Fruit and Vegetable

2013 RESEARCH REPORT

PR-673

RESEARCH

AGRICULTURAL EXPERIMENT STATION

UNIVERSITY OF KENTUCKY COLLEGE OF AGRICULTURE, FOOD AND ENVIRONMENT, LEXINGTON, KY, 40546

University of Kentucky • Lexington, Kentucky 40546

Acknowledgments

Grants from the Agricultural

Development Board through the

Kentucky Horticulture Council have

allowed an expansion of the eld

research and demonstration program to

meet the informational and educational

needs of our growing vegetable and fruit

industries.

Important note to readers:

The majority of research reports in this

volume do not include treatments with

experimental pesticides. It should be

understood that any experi-mental

pesticide must rst be labeled for the

crop in question before it can be used by

growers, regardless of how it might have

been used in research trials. The most

recent product label is the nal authority

concerning application rates, precautions,

harvest intervals, and other relevant

information. Contact your county’s

Cooperative Extension oce if you need

assistance in interpreting pesticide labels.

This is a progress report and may

not reect exactly the nal outcome

of ongoing projects. Please do not

reproduce project reports for distribution

without permission of the authors.

2013 Fruit and Vegetable Crops Research Report

Edited by Shubin K. Saha, John Snyder and Chris Smigell

CONTRIBUTORS

Horticulture

Chair

Robert L. Houtz

Faculty

Doug Archbold

Shubin K. Saha

John Snyder

John Strang

Patsy Wilson

Area Extension Associates

Ty Cato, Shelbyville, Louisville metro area

(vegetables)

Chris Smigell, Lexington, central Kentucky

(small fruits)

Dave Spalding, Lexington, central Kentucky

(vegetables)

Horticulture Farm Manager

Mark Williams (Interim)

Horticulture Organic Farming Research

and Education Unit and CSA Manager

Tiany Thompson

Horticulture Professional Sta assisting

with projects included in this report

Dave Lowry

Sean Lynch

Joseph Tucker

Je Wheeler

Neal Wilson

Dwight Wolfe

Lucas Hanks

Entomology

Faculty

Ric Bessin

Graduate Students

Amanda Skidmore

Rachelyn Dobson

Plant Pathology

Faculty

Kenny Seebold

Nicole Ward

Professional Sta

Julie Beale

Brenda Kennedy

Sara Long

Nutrition and Food Science

Faculty

Pam Sigler

Food Systems Innovation Center

Angela Anandappa

Extension Agents

Agriculture and Natural Resources and

Horticulture (county research sites)

Caldwell Co., Shane Bogle

Campbell Co., DJ Scully, David Koester,

Clark Co., David Davis

Fayette Co., Nick Carter, Jamie Dockery

Franklin Co., Keenan Bishop, Lora Bailey

Gallatin Co., David Hull

Garrard Co., Jay Hettmansperger

Jeerson Co., Wayne Long, Sarah Stolz

Madison Co., Brandon Sears, Amanda Sears

Oldham Co., Tracy M. Missun

Shelby Co., Corinne Kephart

Spencer Co., Bryce Roberts

Kentucky State University

College of Agriculture Food Science and

Sustainable Systems

Dean

Dr. Teferi Tsegaye

Faculty

George F. Antonious

John D. Sedlacek

Maifan Silitonga

Kirk Pomper

Professional Sta

Jon Cambron

Karen Friley

Sherry Crabtree

Irina Howard

Jeremiah Lowe

Joni Nelson

Anthony Silvernail

Berea College

Agriculture and Natural Resources Program

Faculty

Sean Clark

Assistant Farm Manager

Janet Meyer

Cover: Trellised seedless cucumbers grown in

a high tunnel.

Several of the research reports presented in

this document were partially funded by the

Kentucky Agricultural Development Board

through a grant to the Kentucky Horticulture

Council.

Mention or display of a trademark,

proprietary product, or rm in text or gures

does not constitute an endorsement and

does not imply approval to the exclusion of

other suitable products or rms.

Contents

e 2013 Fruit and Vegetable Crops Research Program ................................................................. 3

Demonstrations

On-Farm Commercial Vegetable Demonstrations ...........................................................................4

On-Farm Commercial Vegetable Demonstrations ...........................................................................6

Diagnostic Laboratory

Fruit and Vegetable Disease Observations

from the Plant Disease Diagnostic Laboratory—2013 ......................................................... 7

Tree Fruits

Rootstock Effects on Apple and Peach Tree Growth and Yield ...................................................9

Feasibility Study of Organic Apple Production in Kentucky ...................................................... 11

Small Fruit and Grapes

e ‘Prime-Jan®’ and ‘Prime-Ark®45’ orny

Primocane-fruiting Blackberry Trial ...................................................................................... 13

Organic Grape Cultivar Evaluation Trial in Kentucky .................................................................. 14

Leafhoppers Associated with Newly Established

Primocane Blackberry and Raspberry Plantings in Central Kentucky ....................... 16

Wine and Seedles Table Grape Cultivar Evaluation Trial ........................................................... 18

Rabbiteye Blueberry Variety Evaluation, 2013 ................................................................................. 21

Advanced orny and ornless

Primocane-fruiting Blackberry Selection Trial ................................................................... 22

Vegetables

Bell Pepper Bacterial Spot Variety Trial, Central Kentucky ........................................................ 23

Spring Red and Savoy Cabbage Variety Evaluation ....................................................................... 25

Managing Brown Marmorated Stink Bug

using Selective Exclusion Screening Materials .................................................................... 29

Developing More Resilient Cantaloupe Production Systems .................................................... 30

Financial Comparison of Organic Potato Production Using

Different Integrated Pest Management Systems ................................................................. 33

Effect of Municipal Refuse Compost and Chicken Manure

Applications on Kale and Collard Green Yields and Quality.......................................... 37

Asparagus Variety Evaluation ................................................................................................................ 40

Appendix A: Sources of Vegetable Seeds .......................................................................................... 41

3

INTRODUCTION

6

7

8

1. C ampbell

2. Caldwell

9. Madison

10. Oldham

7. Gallatin

8. Jeerson

1

3

2

4

10

5

9

11

12

3. Clark

4. Fayette

11. Shelby

12. Spence

r

5. Franklin

6. Garrard

Fruit and vegetable research

sites in 2013.

The 2013 Fruit and Vegetable Crops Research Program

Shubin K. Saha, Department of Horticulture

Fruit and vegetable production in Kentucky continues to

grow. e 2013 Fruit and Vegetable crops research report in-

cludes results for more than 15 field research plots and multiple

demonstration trials. is year fruit and vegetable research and

demonstration trials were conducted in more than 12 counties

in Kentucky (see map, right). Research was conducted by fac-

ulty and staff from several departments within the University

of Kentucky College of Agriculture including: Horticulture,

Plant Pathology, and Entomology. is report also includes

collaborative research projects conducted with faculty and staff

at Kentucky State University and Berea College.

Variety trials included in this year’s publication include:

cabbage, asparagus, bell peppers, blueberries, blackberries,

raspberries, apples, peaches, and grapes. Additional research

trials include organic management of cucumber beetles, finan-

cial comparison of organic potato integrated pest management

systems, and effect of organic fertilizer materials for production

of kale. Variety trials provide us with much of the information

necessary to update our recommendations in our Vegetable

Production Guide for Commercial Growers (ID-36). However,

when making decisions about what varieties to include in ID-

36, we factor in performance of varieties at multiple locations

in Kentucky over multiple years. We may also collaborate with

researchers in surrounding states to discuss results of variety

trials they have conducted. Only then after much research and

analysis will we make variety recommendations for Kentucky.

e results presented in this publication often reflect a single

year of data at a limited number of locations. Although some

varieties perform well across Kentucky year after year, others

may not. Here are some helpful guidelines for interpreting the

results of fruit and vegetable variety trials:

Our Yields vs. Your Yields

Yields reported in variety trial results are extrapolated from

small plots. Depending on the crop, individual plots range from

8 to 200 plants. Our yields are calculated by multiplying the

yields in these small plots by correction factors to estimate per-

acre yield. For example, if you can plant 4,200 tomato plants per

acre (assuming 18” within row spacing) and our trials only have

10 plants per plot, we must multiply our average plot yields by a

factor of 420 to calculate per acre yields. us, small errors can

be greatly amplified. Furthermore, because we do not include

factors such as drive rows in our calculations, our per-acre yields

are typically much higher than what is found on an average farm.

Due to the availability of labor, research plots may be harvested

more often than would be economically possible. Keep this in

mind when reviewing the research papers in this publication.

Statistics

Often yield or quality data will be presented in tables

followed by a series of letters (a, ab, bc, etc.). ese letters

indicate if the yields of the varieties are statistically different.

Two varieties may have average yields that appear to be quite

different. For example if tomato variety 1 has an average yield

of 2000 boxes per acre and variety 2 yields 2300 boxes per acre

one would as-sume that variety 2 had a greater yield. However,

just because the two varieties had different average yields, does

not mean that they are statistically or significantly different. In

the tomato example, variety 1 may have consisted of four plots

with yields of 1800, 1900, 2200, and 2100 boxes per acre. e

average yield would then be 2000 boxes per acre. Tomato variety

2 may have had four plots with yields of 1700, 2500, 2800, and

2200 boxes per acre. e four plots together would average

2300 boxes per acre. e tomato varieties have plots with yield

averages that overlap, and therefore would not be considered

statistically dif-ferent, even though the average per acre yields

for the two varieties appear to be quite different. is example

also demonstrates variability. Good varieties are those that not

only yield well, but have little variation. Tomato variety 2 may

have had similar yields as variety 1, but also had much greater

variation. erefore, all other things being equal, tomato variety

1 may be a better choice, due to less variation in the field.

Statistical significance is shown in tables by the letters that

follow a given number. For example, when two varieties have

yields followed by completely different letters than they are

significantly different; however, if they share even one letter

then statistically they are no different. us a variety with a yield

that is followed by the letters ‘bcd’ would be no different than

a variety followed by the letters ‘cdef,’ because the letters ‘c’ and

‘d’ are shared by the two varieties. Yield data for followed by the

letters ‘abc’ would be different yield data followed by ‘efg.’

Lastly when determining statistical significance we typically

use a ‘P’ value of 0.05. In this case, P stands for probability and the

0.05 means that we have a 5% chance that our results are real and

not simply due to chance or error. Put another way, if two variet-

ies are said to be different at P<0.05, then at least 95% of the time

those varieties will be different. If the P value is 0.01, then 99% of

the time those varieties will be different. Different P values can

be used, but typically P < 0.05 is considered standard practice.

is may be confusing, but without statistics our results

wouldn’t be useful. Using statistics ensures that we can make

more accurate recommendations for farmers in Kentucky.

4

DEMONSTRATIONS

On-Farm Commercial Vegetable Demonstrations

Ty Cato, Department of Horticulture

Introduction

Five on-farm commercial vegetable production demonstra-

tions were conducted in the north central part of the state, in

Oldham, Jefferson, and Spencer Counties. ese locations were

chosen due to the recent surge in commercial vegetable pro-

duction to supply the Louisville area demand for locally grown

food. ree growers in Jefferson County, one grower in Spencer

County, and one grower in Oldham County were chosen for

this demonstration. e Oldham County grower produced

mixed vegetables on 0.62 acres for local farmers markets and

a CSA (Community Supported Agriculture.) e growers in

Jefferson County grew 1.53 acres, 1.54 acres, and 0.87 acres of

mixed vegetables, respectively. e first grower operated a CSA

and sold to farmers markets. e second grower provided his

Louisville-based restaurant with produce from the plot. e

third grower sold at an on-farm store and farmer’s markets, as

well as producing value added products for sale, such as salsas

and sauces. e Spencer County grower grew 0.43 acres of

mixed vegetables and sold at a farmers market.

Materials and Methods

e growers were provided with plastic mulch and drip tape

for up to one acre of production. e University of Kentucky

Horticulture Department also provided a bed-shaper/plastic

layer, a water-wheel transplanter, and a plastic mulch lifter to

remove the mulch at the end of the growing season. All other

inputs including fertilizer, pesticides, irrigation pumps, and

labor (both manual and mechanical) were provided by the

grower. e grower recorded basic information such as yield

data, input costs, etc. An extension associate from the Depart-

ment of Horticulture made weekly visits to provide assistance

with disease management, harvesting practices, and any other

production issue needing attention. e extension associate was

also involved in setting up demonstration field days to display

commercial vegetable production techniques to other growers

interested in producing vegetables.

Conventional, certified organic, and all natural growing

practices were used in the demonstration plots. ree plots

were conventional, relying on synthetic fertilizer, herbicides,

insecticides, and fungicides. One plot was certified organic and

the last plot was maintained using organic practices, without

organic certification. e five demonstrations used raised beds

with plastic mulch sealed on top of the beds. e height of the

beds ranged from six to eight inches and the plastic used was

either black 1 mil for early season crops or white on black 1 mil

for late season crops. e black plastic provides transplants with

the heat that they need early in the growing season, whereas the

white on black plastic reflects the heat of the sun away from the

bed, reducing heat stress on transplants set in the heat of the

summer.

Results and Discussion

e 2013 growing season presented some problems for com-

mercial producers in north central Kentucky. e first problem

was very cool spring temperatures that delayed the transplant-

ing date of early spring crops. While not a huge problem, it did

delay yields on certain crops by one to two weeks.

Second, a period of heavy rain, lasting approximately five

to seven days in early June promoted the development of

Septoria leaf blight on tomatoes. e disease did not become

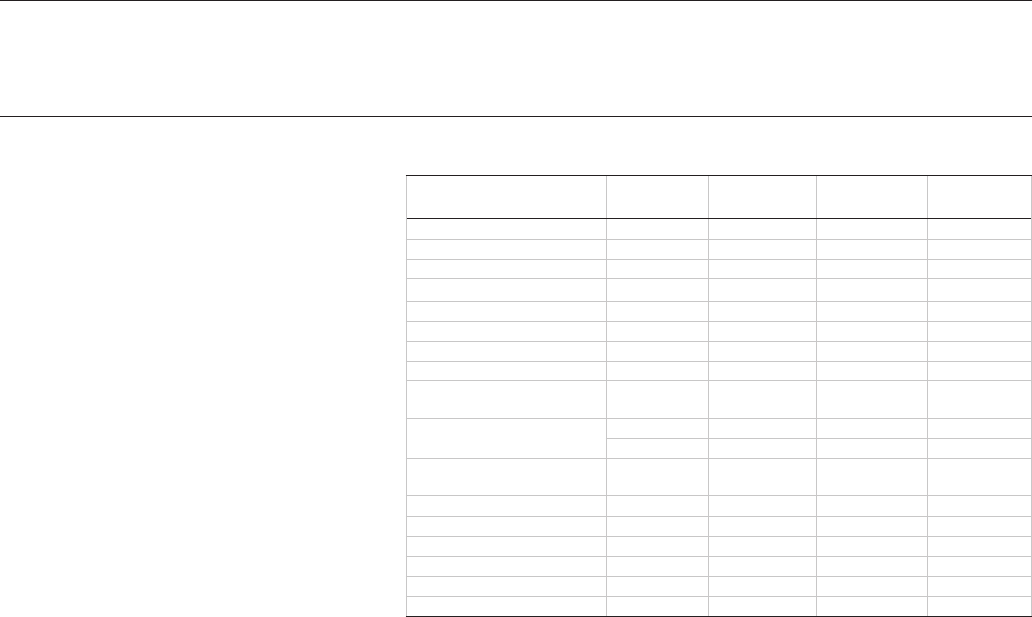

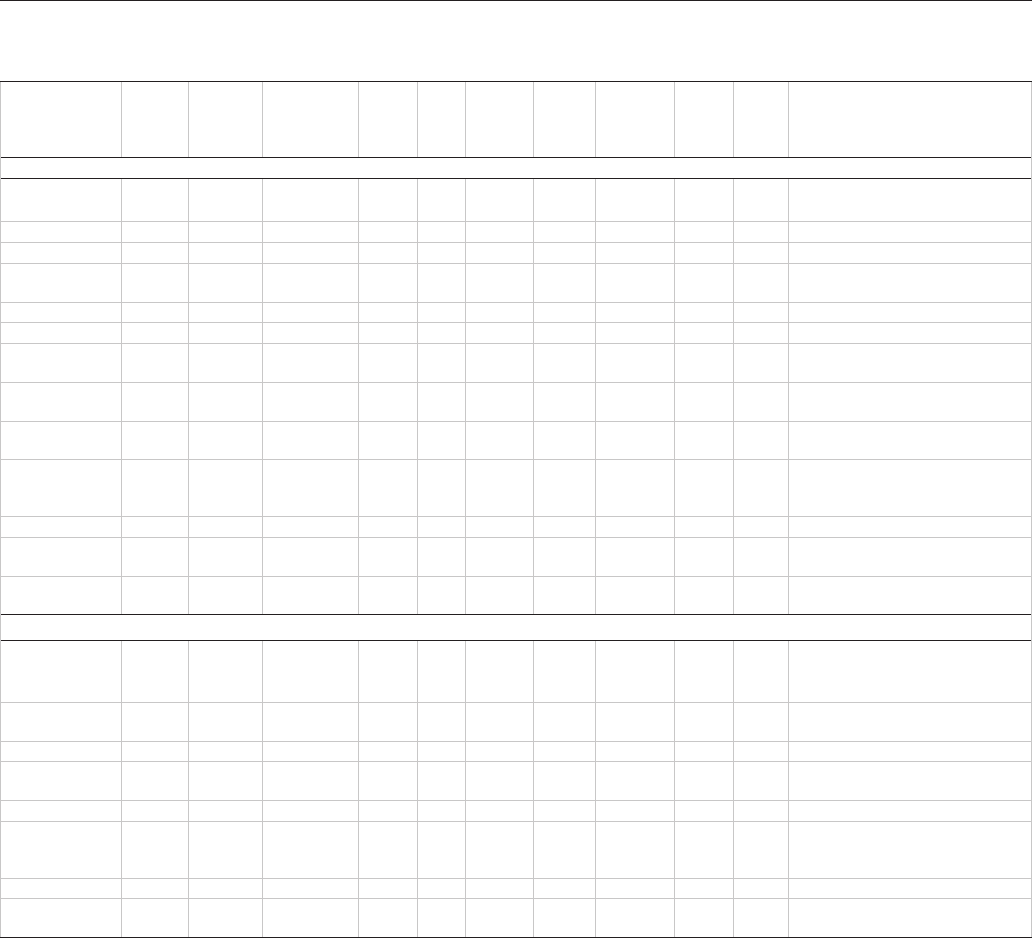

Table 1: Costs and prots for mixed vegetable plots, Jeerson, Oldham, Spencer Counties, 2013

Jeerson

Conventional 1 Oldham All Natural

Spencer

Conventional

Jeerson

Conventional 2 Jeerson Organic

Plot Acreage 0.9 0.6 0.4 1.5 1.5

Inputs

Plants and Seeds $1013.00 $280.00 $112.26 $2534.42 $700.00

Fertilizer 487.00 82.76 43.75 120.00 1100.00

Plastic Mulch 189.00 86.40 69.30 204.00 180.00

Drip Lines 126.00 57.60 46.20 136.00 119.00

Fertilizer Injector and Irrigation Fittings 728.00 N/A 841.14 175.00 N/A

Herbicide N/A N/A N/A 100.00 N/A

Insecticide 110.00 8.00 N/A 100.00 110.00

Fungicide N/A 20.00 N/A N/A N/A

Water 900.00 154.80 Pond 200.00 900.00

Manual Labor 1450.00 2024.29 1240.00 1218.10 8000.00

Machine Labor (Fuel cost) 125.00 38.25 74.25 1488.55 1400.00

Marketing N/A 166.50 109.75 2086.39 N/A

Total Expenses 5128.00 2918.60 2536.65 8362.46 12509.00

Yield * * * * *

Revenue 4744.00 10140.75 483.50 14540.00 8600.00

Prot -$384.00 $7222.15 -$2053.15 $6177.54 -$3458.00

*

Yields for mixed vegetable production varybased on crops

5

DEMONSTRATIONS

a significant problem until another soaking rain about a week

later, in which the disease spread rapidly, as the Septoria fungus

spreads by splashing rain. Combined with early blight, Septoria

severely damaged tomato plants, thus limiting yields. Organic

growers tried to prevent the spread by removing infected foliage

from the field and applying preventative fixed copper sprays.

Conventional growers tried to slow disease development and

dispersal of inoculum using fungicides such as azoxystrobin,

within a rotational schedule including chlorothalonil.

Powdery mildew became a problem later, affecting pump-

kins, summer squash, and cucumbers primarily. is disease

could be managed with a myclobutanil fungicide, in a rotation

of other preventative sprays. Most heavily damaged summer

squash plantings were removed and replanted, because of rapid

plant growth and quick fruit set.

One of the biggest problems for the cooperating growers this

season was deer feeding damage. One Jefferson County grower’s

entire tomato crop was devastated by deer. e Spencer County

grower lost all of his sweet potatoes and most of his bush beans

to deer damage. is onslaught of deer was limited by installing

various types of fencing around the plots. Some of the fencing

was far more effective than others. Eight foot tall mesh fencing

seemed more effective than various heights of stranded fishing

line spaced four to five feet apart. e organic grower installed a

twelve foot tall barbed wire fence around his entire farm. While

this was by far the most effective, it was also cost prohibitive for

most growers.

Weed pressure was only a major problem with one grower,

due to a miscommunication regarding what herbicides can be

applied between the beds. is issue was rectified mid-summer

and the weeds were no longer at an unacceptable level for the

remainder of the season.

Other issues reduced the profitability of the demonstra-

tion plots. Whether it was not having access to a market soon

enough, delayed and/or greatly diminished yields due to abiotic

and biotic factors, or post-harvest loss due to bacterial soft rot,

all of these contributed to low profits by some of the growers

(Table 1). Labor issues affected growers as well. Not having

enough help for harvest caused some crops to be lost with no

profit seen. Initial start-up costs for conventional growers greatly

reduced profitability as well. ese initial costs were for one time

investments (e.g. equipment) that could be amortized over the

useable life of the product, thus leading to increased profits in

the years to come.

6

DEMONSTRATIONS

On-Farm Commercial Vegetable Demonstrations

Dave Spalding, Department of Horticulture

Introduction

Four on-farm commercial demonstra-

tions were conducted in central and northern

Kentucky in 2013. Grower/cooperators were

from Campbell, Clark, Gallatin, and Garrard

counties. e grower/cooperator in Campbell

County grew 0.50 acre of mixed cut flowers

and fall vegetables (including squash, gourds

and pumpkins) for local farmers markets. e

grower/cooperator in Clark County grew ap-

proximately 1.0 acre of mixed vegetables for the

local farmers market. e grower/cooperator in

Gallatin County grew 3.0 acre of tomatoes, 1.0

acre of cantaloupe, 1.0 acre of watermelon, 1.0

acre of pumpkins and 3.0 acres of sweet corn

for the local wholesale and retail markets. e

Garrard County grower/cooperator grew about

0.50 acre of mixed vegetables for a local CSA

market. Two demonstration plots, one in Clark

and one in Madison County were abandoned in

mid-summer due primarily to a lack of available

labor.

Materials and Methods

Grower/cooperators were provided with black plastic

mulch and drip lines for up to 1 acre and the use of the University

of Kentucky horticulture department’s equipment for raised–

bed preparation and transplanting. e cooperators supplied

all other inputs, including labor and management of the crop.

In addition to identifying and working closely with cooperators,

county extension agents took soil samples from each plot and

scheduled, promoted, and coordinated field days at each site.

An extension associate made regular weekly visits to each plot

to scout the crop and make appropriate recommendations.

e plots were planted into raised beds covered with black

plastic mulch and drip tape under the plastic in the center of the

beds. e mixed vegetable plots were planted at the appropri-

ate spacing for the vegetable being grown (i.e. tomatoes were

planted in a single row 18 inches apart; beans were planted in

double rows 12 inches apart, etc.). e bell pepper only plot

was planted into raised beds with the bell peppers planted in

double rows 18 inches apart in the row. Except for the organic

plots, the others were sprayed with the appropriate fungicides

and insecticides as needed, and cooperators were asked to fol-

low the fertigation schedule provided.

Results and Discussion

Weather conditions in 2013 were less than ideal for veg-

etable production. An abnormally wet and cool spring gave way

to a wet and mostly cool summer for much of Central Kentucky.

Despite the wet conditions, most crops were planted at typical

times. After most crops were planted and growing, the weather

stayed relatively cool and wet for most of the summer. e cool

and wet conditions that persisted for most of the growing season

were conducive to increased disease and fertility problems.

However the biggest problem for most growers, particularly

the organic growers, was weeds.

e grower/cooperator in Gallatin County used a white

plastic mulch for part of his production. White plastic use in

early season production did not appear to perform as well as

the traditional black plastic. is is likely a result of the black

plastic warming the soil for good early season establishment of

transplants. However, when used in later plantings the results

were better with most of the improvement coming from a higher

survival rate of transplants, as a result of maintaining cooler

soil temperatures. ese findings were essentially the same as

observed the previous year.

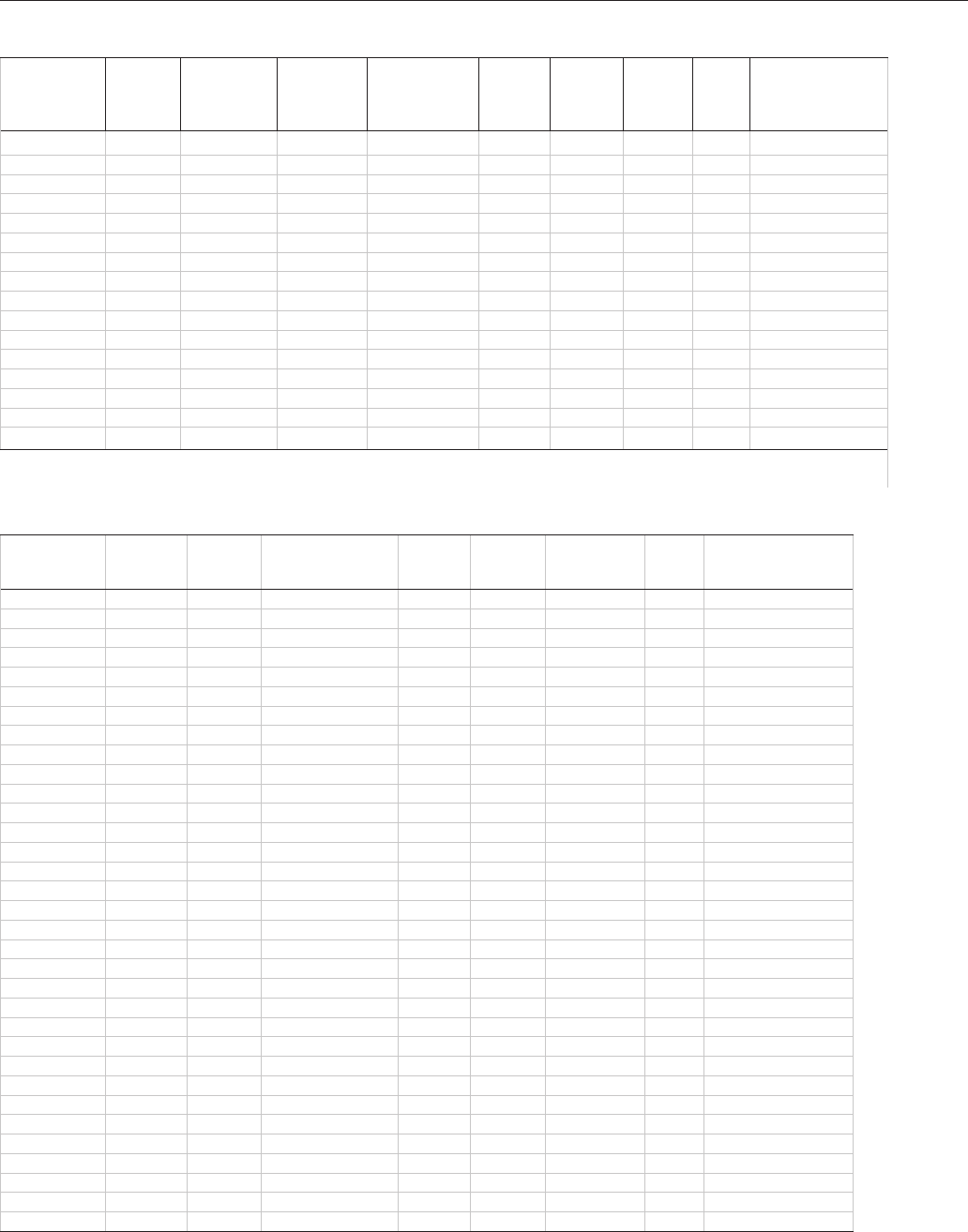

Table 1. Costs and returns of grower/cooperators, Central Kentucky, 2013.

Inputs

Campbell

(0.50 acre)

Clark

(1.0 acre)

Gallatin

(3.0 acre)

Garrard

(0.50 acre)

Plants and Seeds $210.00 $400.00 $3,300.00 $110.00

Fertilizer 300.00 431.00 1,800.00 240.00

Black Plastic 86.00 186.00 558.00 86.00

Drip Lines 81.00 162.00 486.00 81.00

Fertilizer Injector 0 60.00* 60.00* 0

Herbicide 0 31.98 120.00 0

Insecticide 0 56.22 475.00 0

Fungicide 0 179.08 581.00 85.00

Water 105.00

( 80,00 gal )

419.11

(186,000 gal)

3,200.00**

(550,000 gal)

125.00

(70,000 gal)

Labor 0 0 18,210.00 0

(300 hrs)**** (327 hrs )**** (29,450 hrs)*** (240 hrs )****

Machine 230.40

(24 hrs)

128.20

(13 hrs)

4,500.00

(420 hrs)

87.12

(9.50 hrs)

Marketing 250.00 977.10 3,350.00 25.00

Total Expenses 1,262.40 3,030.69 36,640.00 839.12

Income 1,950.00 11,942.00 72,279.45 900.00

Net Income 687.60 8,911.31 35,639.45 60.88

Net Income/Acre 1,375.20 8,911.31 11,879.82 121.76

Dollar Return /Dollar Input 1.54 3.94 1.97 1.07

*

Costs amortized over three years.

**

Cost of electric usage and 5 year amortized cost of pump.

***

Includes unpaid volunteer or family labor.

****

All unpaid family labor.

7

DIAGNOSTIC LABORATORY

Fruit and Vegetable Disease Observations

from the Plant Disease Diagnostic Laboratory—2013

Julie Beale, Paul Bachi, Brenda Kennedy, Sara Long, Kenny Seebold, and Nicole Ward, Department of Plant Pathology

Introduction

Plant disease diagnosis and formulation of disease man-

agement recommendations are the result of U.K. College of

Agriculture Research (Agricultural Experiment Station) and

Cooperative Extension Service activities through the Depart-

ment of Plant Pathology. We maintain two branches of the

Plant Disease Diagnostic Laboratory (PDDL), one on the U.K.

campus in Lexington, and one at the U.K. Research and Educa-

tion Center in Princeton. Two full-time diagnosticians and a

full-time diagnostic assistant are employed in the PDDL; exten-

sion specialists Drs. Kenny Seebold and Nicole Ward provide

diagnostic and disease management expertise in vegetable and

fruit crops, respectively.

Most plant samples are submitted to the PDDL by county

extension agents on behalf of their local growers and home

gardeners. Fruit and vegetable samples comprised roughly one-

third of the approximately 3,500 plant specimens examined in

2013. One-half of fruit and vegetable samples were from com-

mercial growers (1).

Materials and Methods

Fruit and vegetable disease diagnosis involves a great deal

of investigation into the possible causes of disease symptoms.

Most visual diagnoses include microscopy to determine plant

parts that are affected and to identify the pathogen(s) involved.

In addition, many specimens require specific tests such as moist

chamber incubation, isolation onto culture media, enzyme-

linked immunosorbent assay (ELISA), polymerase chain reac-

tion (PCR) assay, nematode extraction, or soil pH and soluble

salts tests. Fruits and vegetables are high value crops for which

a high proportion of diagnostic samples require specialized

testing and/or consultation with U.K. faculty plant pathologists

and horticulturists. Computer-based laboratory records are

maintained to provide information used in conducting plant

disease surveys, identifying new disease outbreaks, and formu-

lating educational programs. All diagnoses of plant diseases are

reported to a national repository.

Results and Discussion

Abundant rain throughout much of the 2013 growing

season and generally cool temperatures favored development

of many plant diseases, particularly those caused by fungi and

oomycetes. e following summary includes the predominant

diseases submitted as diagnostic samples, as well as a description

of several unusual or significant diseases of fruit and vegetable

crops.

New, Emerging, and Problematic Fruit and

Vegetable Diseases in Kentucky

Phytophthora root rot on blueberry (Phytophthora

cinnamomi) has been seen more and more frequently in

Kentucky in recent years and was a serious problem for blue-

berry producers in 2013. Wet soils favor disease development

and spread, and the pathogen can survive in soil for extended

periods. Extension programs to educate growers on disease

prevention and management were initiated in response to this

increasing problem.

Strawberry viruses were a source of concern for some

growers in Kentucky and elsewhere in the eastern U.S. this

spring. Plants with dual infections of strawberry mottle virus

(SMoV) and strawberry mild yellow edge virus (SMYEV) were

released from a Nova Scotia nursery. Symptomatic plants from

this source that had been planted on a Kentucky farm were

sent to the USDA-ARS Horticulture Crops Research Unit in

Corvallis, OR, for testing, and presence of the two viruses was

confirmed. Infected plants exhibited symptoms of stunting,

slight leaf distortion and mild yellowing, particularly at leaf

margins. General recommendations for management were

removal of infected plants in order to reduce the risk of spread

to nearby healthy plants, implementation of an insect-control

program to reduce the aphid vector and weed management to

minimize risk of virus carryover in weed hosts.

Tomato spotted wilt virus (TSWV) was not observed

as commonly as in 2012 but was still an important disease in

tomato. Incidence was typically low in a given field, but when

the virus was detected in tomatoes in greenhouse/high tun-

nel structures, incidence tended to be quite high. A range of

symptoms was observed.

Late blight (Phytophthora infestans) was not widespread

in Kentucky but was diagnosed in tomato in four counties and

did cause significant plant loss where it occurred. Kentucky

isolates of P. infestans were submitted for strain identification

as part of a regional project at Cornell University and were

determined to belong to clonal lineage US-23.

Cucurbit downy mildew (Pseudoperonospora cubensis)

developed earlier than usual this year (first confirmation in

Kentucky on July 25) and resulted in severe canopy loss in some

areas.

Tree Fruit Diseases

Pome fruits. Cedar-apple rust (Gymnosporangium

juniperi-virginianae) occurred at high levels on susceptible

apple varieties; frequent rains in spring favored infection.

Levels of scab (Venturia inaequalis) and frogeye leaf spot

8

DIAGNOSTIC LABORATORY

(Botryosphaeria obtusa) were moderate. Although fire blight

(Erwinia amylovora) was seen, cooler temperatures during

bloom reduced incidence of infections. Fruit rots—especially

bitter rot (Glomerella cingulata)—were common in late sum-

mer. read blight (Corticium stevensii) was diagnosed on pear.

is disease is rarely seen except in wet years and in humid/

shaded locations.

Stone fruits. Brown rot (Monilinia fructicola) was the

most commonly observed stone fruit disease and affected

peach, nectarine and cherry. Limited incidence and severity of

bacterial leaf spot (Xanthomonas campestris pv. pruni) and

scab (Venturia carpophila) were recorded on peach.

Small Fruit Diseases

Grapes. Anthracnose (Elsinoe ampelina) and black rot

(Guignardia bidwellii) were common. Bitter rot (Melanco-

nium fuligineum) was also diagnosed several times in western

Kentucky on ‘Cabernet Franc’ from commercial vineyards and

‘Concord’ from home fruit plantings. Superficial symptoms of

this fruit rot are similar to those of black rot or Phomopsis fruit

rot. Downy mildew (Plasmopara viticola) was first diagnosed

in July, which is fairly typical in our area, and was a full month

later than in 2012. Several cases of leaf blight (Isariopsis clav-

ispora) were diagnosed as a late-season foliar disease.

Brambles. Cane and leaf rust (Kuehneola uredinis) was

diagnosed on multiple blackberry samples, as well as a few cases

of cane blight (Leptosphaeria coniothyrium) and spur blight

(Didymella applanata). Raspberry ringspot virus (RpRSV)

was confirmed via ELISA on both black raspberry and black-

berry.

Blueberries. Root and collar rot (Phytophthora cinna-

momi) was extremely common on blueberry. Various fungal

stem canker/blight diseases were also seen (Botyrosphaeria

sp., Phoma sp., Phomopsis sp.)

Strawberries. Leaf blight (Phomopsis obscurans) was

seen frequently on strawberry. Strawberry mottle virus (SMoV)

and strawberry mild yellow edge virus (SMYEV) were con-

firmed in Kentucky (see above).

Vegetable diseases

Beans and peas. Foliar/pod diseases, including angular leaf

spot (Phaeoisariopsis griseola) and anthracnose (Glomerella

lindemuthiana), were common due to frequent rains. Com-

mon bacterial blight (Xanothomonas campestris pv. phaseoli)

on bean and bacterial blight (Pseudomonas syringae pv. pisi)

on pea were both diagnosed on home garden samples.

Cole crops. Few diseases were observed on cole crops.

White leaf spot (Mycosphaerella capesllae) was diagnosed

on turnip and Chinese cabbage in autumn.

Cucurbits. Bacterial wilt (Erwinia tracheiphila) was a

problem on cantaloupe early in the season in areas where striped

cucumber beetle pressure was high. Angular leaf spot (Pseudo-

monas syringae pv. lachrymans) also developed on melon and

squash in early summer. Downy mildew (Pseudoperonospora

cubensis—see above) and powdery mildew (Sphaerotheca

fuliginea) became a problem later in the season on cucumber

and pumpkin. Gummy stem blight (Didymella bryoniae) was

diagnosed frequently, particularly on watermelon. A few cases

of Phytophthora blight (Phytophthora capsici) were diagnosed

on pumpkin and winter squash.

Peppers. Bacterial spot (Xanthomonas campestris pv.

vesicatoria) was common on pepper. Few other pepper diseases

were observed.

Tomatoes. e foliar diseases early blight (Alternaria

solani) and Septoria leaf spot (Septoria lycopersici) were com-

mon in field production and home gardens. ese diseases plus

leaf mold (Fulvia fulva) were prevalent in greenhouse/high

tunnel systems. Timber rot (Sclerotinia sclerotiorum) and

tobacco mosaic virus and tomato spotted wilt virus (see above)

were also common in structures. Late blight (Phytophthora

infestans) affected tomato plantings in certain areas (see above).

Other vegetables. Root-knot nematode (Meloidogyne

incognita) was seen frequently on potato, and severe scurf

(Monilochaetes infuscans) was diagnosed on sweet potato

from several locations.

Fruits and vegetables are high value crops. Because many

of them are new or expanding crops in Kentucky and involve

production systems unfamiliar to Kentucky growers, disease

diagnosis and management are even more critical. e PDDL

is an important resource for extension agents and the growers

they assist. e PDDL encourages county extension agents to

include in their programming the importance of accurate dis-

ease diagnosis and timely sample submission. e information

gained from diagnostic analyses will help improve production

practices and reduce disease occurrences and epidemics.

e PDDL relies on funds from the National Plant Diagnostic

Network and IPM grants to help defray some of the laboratory

operating costs.

Literature Cited

Bachi, P., J. Beale, D. Hershman, B. Kennedy, S. Long, K. Seebold,

P. Vincelli and N. Ward. 2014. Plant Diseases in Kentucky -

Plant Disease Diagnostic Laboratory Summary, 2013. U.K.

Department of Plant Pathology (in press).

9

TREE FRUITS

Rootstock Eects on Apple and Peach Tree Growth and Yield

Dwight Wolfe, Doug Archbold, June Johnston, and Ginny Travis, Department of Horticulture

Introduction

Although apple and peach are the principal tree fruits grown

in Kentucky, the hot and humid summers and heavy clay soils

make their production more difficult here than in some neigh-

boring tree fruit producing regions. e hot, humid summers

lead to high disease and insect pressure in Kentucky orchards.

Despite these challenges, orchards can offer high per-acre in-

come and are suitable for rolling hills and upland soils.

Identification of improved rootstocks and cultivars is

fundamental for advancing the Kentucky tree fruit industry.

For this reason, Kentucky cooperates with 39 other states and

three Canadian provinces in the Cooperative Regional NC-140

Project entitled “Improving Economic and Environmental Sus-

tainability in Tree Fruit Production through Changes in Root-

stock Use.” e NC-140 trials are critical to Kentucky growers,

allowing access to and testing of new rootstocks from around

the world. e detailed and objective evaluations allow growers

to select the most appropriate rootstocks for Kentucky.

e NC-140 orchards are research trials that also serve as

demonstration plots for visiting fruit growers, extension person-

nel, and researchers. e data collected from these trials helps

establish baseline production and economic records for the

various orchard system/rootstock combinations that can be

used by Kentucky fruit growers.

Materials and Methods

Grafts of known cultivars on the various rootstocks were

produced by nurseries on the West Coast and distributed to

cooperators. Kentucky’s NC-140 rootstock plantings are lo-

cated at the UK Research and Education Center (UKREC) at

Princeton. ey are:

1. e 2009 peach rootstock trial compares fourteen root-

stocks with ‘Redhaven’ as the scion cultivar. Eight trees of

each rootstock were planted in a randomized complete

block design with eight replications (blocks). Trees were

planted in March 2009 on a 16 ft x 20 ft spacing.

2. e 2010 apple rootstock trial is a planting of ‘Aztec Fuji’

apple on thirty-one different rootstocks with four blocks

per rootstock and up to three trees per rootstock per block.

It was planted in March 2010. e experimental design was

a randomized complete block design, and trickle irrigation

was installed a month after planting. Heavy spring rains

resulted in many of the graft unions sinking below ground

level. Many of the trees were dug up, reset, and allowed to

resettle through the summer. e heights of the graft unions

above the soil line now average five inches with a range of

from three to seven inches.

Orchard floor management for these trials consists of

6.5 ft bare ground, herbicide-treated strips with mowed sod

alleyways. Trees are fertilized and sprayed with pesticides

according to local recommendations (1, 2). Yield and trunk

circumference measurements are recorded for both trials and

trunk cross-sectional area (TCSA) is calculated from the trunk

circumference measurements taken 12 inches above the graft

union for apple, and six inches above for peach. Cumulative

yield efficiency is the cumulative yield (total of all the annual

yields) divided by the current year’s trunk cross-sectional area

of the tree. e TCSA is an indicator of the proportion of nutri-

ent resources a tree is putting into fruit production relative to

vegetative growth. Tree height and canopy spread (the average

of the within-row and across-row tree widths) are recorded at

the end of the fifth and the final (usually the tenth) seasons of

each trial. Fruit size is calculated as the average weight (oz) per

fruit. All data is statistically analyzed using SAS v.9.3

3

.

Results and Discussion

e 2013 growing season in Kentucky started late with be-

low normal temperatures and above normal rainfall. Monthly

temperature averages were 6

o

F and 5°F above normal for

December and January, respectively. Temperatures were 6°F

below normal for March and 2°F below normal for July and

August. Princeton had 16 days at or above 90°F compared to

54 in 2012. Monthly precipitation averages across the state for

2013 were above normal for all but February and May. June and

July monthly averages were 1.6 and 1.8 inches above normal,

respectively. In Princeton, temperatures dipped to 29

o

F on the

mornings of April 2, 3, and 5, and just below freezing on April

20 and 25. Peaches bloomed and matured about 25 days later

than in 2012.

1. 2009 Peach Rootstock Trial

e first year yield data was collected from this trial was

in 2011 (4). e yield in that year was poor due to weather

conditions (hail damage, etc.) and the emergence of the cicada

brood XIX. Most of the peaches harvested would not have

been considered commercial quality even though they met

the commercial size requirements for this trial. In 2012, a crop

that was of commercial size and quality was harvested, in spite

of the early season and season-long drought. In 2013, the third

crop of peaches from this trial was harvested.

Mortality, Julian date of 90% bloom and 10% fruit maturity,

cumulative yield (2011-2013), yield (2013), size, number of

root suckers, trunk cross-sectional area (TCSA), and cumula-

tive yield efficiency varied significantly among the fourteen

rootstocks in this trial (Table 1). Trees on Bright’s Hybrid and

Viking have had the highest mortality rates, 50% and 25%, re-

spectively. e date of 90% bloom averaged less than two days

from first to last with scions on Bright’s Hybrid and Krymsk

86 being the earliest and those on P. americana and Controller

5 being the latest to reach 90% bloom. Fruit maturity was the

latest for scions on Lovell, and earliest by about six days for

scions on Krymsk1 and P. americana. Scions on P. americana

and Krymsk1 averaged the greatest number of root suckers, as

10

TREE FRUITS

Table 1. 2013 results for the 2009 NC-140 peach rootstock planting, Princeton, KY.

Rootstock

1

Tree

Mortality

(% lost)

Julian Date

of 90%

Bloom

Julian Date

of 10%

Maturity

Cumulative

Yield

(2011-2013)

(lbs/tree)

2013

Yield

(lbs/tree)

Fruit

Weight

(oz/fruit)

Number

of Root

Suckers

TCSA

(sq. in)

Cumulative Yield

Eciency

(2011-2013)

(lbs/ sq in TCSA)

Microbac 0 99.6 192.6 113 55.7 6.7 9.6 17.9 6.39

Guardian 0 99.6 191.9 121 72.8 6.5 0.5 16.8 7.24

Krymsk 86 0 99.5 192.0 111 59.8 7.1 0.1 16.5 6.81

Viking 25 100.2 193.2 118 65.6 6.7 0.2 16.2 7.24

Bright’s Hybrid 50 99.5 191.3 77 27.5 6.6 0.5 15.9 4.83

Lovell 0 99.9 196.1 131 76.1 6.9 0.3 15.7 8.37

KV010-127 0 99.9 194.5 118 68.0 6.5 1.0 14.9 7.95

Atlas 0 100.0 190.8 144 89.3 7.1 0.0 14.8 9.37

KV010-123 12.5 100.3 192.6 126 77.4 7.0 0.4 14.4 8.80

HBOK 32 12.5 100.1 194.7 103 62.0 6.5 0.0 12.6 8.23

HBOK 10 0 100.0 192.6 104 65.8 7.0 0.0 11.4 8.94

Controller 5 0 100.9 190.6 87 46.0 6.3 0.0 10.5 8.52

P. americana 12.5 100.9 190.2 71 32.8 6.1 14.0 9.2 7.66

Krymsk 1 12.5 100.3 190.1 38 13.0 6.4 12.7 5.8 6.81

Mean 8.9 100.0 192.4 105 58.1 6.7 2.8 13.7 7.66

LSD (5%) 26.5 0.8 1.66 33 26.0 NS 4.5 2.3 2.13

1

Arranged in descending order of trunk cross-sectional area (TCSA) for each rootstock.

Table 2. 2013 results for the 2010 NC-140 apple rootstock trial, Princeton, KY.

Rootstock

1

Initial

Number

of Trees

Tree

Mortality

(% lost)

Cumulative Yield

(2012-2013)

(lbs/tree)

2013

Yield

(lbs/tree)

Fruit

Weight

(oz/fruit)

Number of

Root Suckers

TCSA

(sq. in.)

Cumulative Yield

Eciency

(lbs/sq in TCSA)

PiAu 9-90 4 0 15.0 7.7 5.1 2.9 9.5 2.04

B.70-20-20 12 0 16.7 10.6 5.1 3.8 9.4 1.80

PiAu 51-11 11 0 22.9 11.0 5.4 0.6 7.2 3.18

B.70-6-8 12 0 22.4 9.0 5.4 0.0 6.8 3.21

B.7-3-150 12 0 26.4 14.7 5.1 0.2 6.6 4.07

B.67-5-32 12 0 20.0 13.2 4.7 1.3 6.5 2.87

G.202 N 8 0 37.4 20.2 6.0 1.0 6.0 6.32

B.64-194 7 0 18.0 9.0 5.1 1.0 5.4 3.29

M.26 EMLA 11 0 27.9 15.2 6.0 0.1 5.3 5.21

G.5222 8 0 39.5 19.8 5.2 3.0 5.3 7.76

G.935 N 10 0 39.6 20.5 6.0 0.3 5.1 7.81

G.4814 4 0 31.0 16.3 5.2 6.5 5.0 6.05

G.3001 3 0 24.2 11.2 5.9 0.1 4.6 4.73

G.4004 4 0 27.5 20.7 5.2 1.3 4.5 6.12

M.9 Pajam2 9 11 24.0 15.2 5.8 8.7 4.4 5.17

G.935 TC 4 0 20.9 12.1 6.0 0.9 4.3 4.93

G.11 8 13 31.7 17.4 6.7 0.4 4.2 7.57

G.202 TC 12 0 26.8 13.2 5.7 0.7 4.2 6.56

Supp.3 5 0 30.4 18.3 7.8 0.5 4.0 7.74

M.9 NAKBT337 12 17 27.1 13.0 6.1 1.6 4.0 6.56

B.10 1 0 16.9 8.4 5.8 0.0 3.6 4.85

G.4013 2 0 6.1 4.4 4.3 0.0 3.2 1.89

G.4214 2 0 13.0 8.6 5.4 0.6 3.1 4.66

G.5087 4 0 20.2 12.1 4.9 0.2 3.0 6.07

G.41 TC 12 0 12.8 12.8 6.0 0.3 2.8 4.44

G.4003 7 0 18.7 9.9 5.7 0.2 2.3 8.19

G.41 N 3 0 9.0 5.9 5.0 0.4 2.1 4.30

B.9 12 8 6.2 3.1 5.9 2.1 1.5 3.87

G.2034 2 0 10.6 7.0 6.1 0.1 1.5 5.32

B.7-20-21 12 0 1.8 1.1 4.9 0.2 1.3 1.28

B.71-7-22 10 20 0.7 0.2 5.2 0.7 0.8 0.33

Means NA 3 20.7 11.7 5.6 1.3 4.4 4.78

LSD (0.05) NS NS 13.9 9.0 NS 3.3 1.7 2.77

1

Arranged in descending order of the fall trunk cross-sectional area (TCSA) for each rootstock.

11

TREE FRUITS

they did in 2012. Microbac continues to be the most vigorous

rootstock and Krymsk 1 the least vigorous in this trial. Yield

per-tree was highest for scions on Atlas and lowest for scions on

Krymsk 1. Cumulative yield was highest for Atlas, but was not

significantly different from that of Lovell, KV010-123, Viking,

Guardian, KV010-127, Microbac, or Krymsk86. Scions on Atlas

also had the highest cumulative yield efficiency. Fruit size did

not differ significantly among rootstocks.

2. 2010 Apple Rootstock Trial

In 2013, no significant differences were observed for mor-

tality or average weight per fruit, but cumulative yield per tree

(2012-2013), yield per tree (2013), number of root suckers,

TCSA, and yield efficiency varied significantly among the 31

rootstocks (Table 2). Trees with PiAu 9-90 and B70-20-20 root-

stocks are the largest, and trees with B.7-20-21 and B.71.7-22

are the smallest. is was the second year that these trees were

harvested, and yield was greatest for scions on G.4004, G.935N,

and G.202N and lowest for B.7-20-21 and B.71-7-22. Root sucker

growth was highest for M.9 Pajam 2, followed by G.4814 and

B.70-20-20. G.4003, followed by G935N, G.5222, Supp.3, and

G.11 had the highest cumulative yield efficiency.

Literature Cited

1. Bessin, R.T., J.G. Strang, S. Wright, and N. Ward. 2013 Mid-

west Tree Fruit Spray Guide. University of Kentucky College

of Agriculture Cooperative Extension Service, Publication

ID-92.

2. Midwest Tree Fruit Pest Management Handbook. Uni-

versity of Kentucky College of Agriculture Cooperative

Extension Service, Publication ID-93.

3. SAS Institute Inc., Cary, NC, USA.

Feasibility Study of Organic Apple Production in Kentucky

Doug Archbold, Mark Williams, John Strang, Department of Horticulture; and Ric Bessin, Department of Entomology

Introduction

Nationally, there is a growing market for organically grown

apples. However, there are no research studies from the mid-

South that extension specialists can refer to that have identified

the challenges that organic apple growers in Kentucky might

face, or that have assessed currently recommended techniques

to address those challenges. Organic apple production tech-

niques (Hinman and Ames, 2011) have never been assessed

under Kentucky growing conditions. e challenges to organic

apple production in Kentucky and the mid-South need to be

clearly identified, so that solutions can be studied, developed,

and recommended. Existing and especially newly emerging

technologies may make organic apple production increasingly

possible.

To determine the feasibility of, and identify the challenges to

organic apple production in Kentucky, a high-density, certified

organic apple orchard was established in 2007 on the University

of Kentucky Horticultural Research Farm in Lexington. is

orchard was managed using organically certified techniques

and materials for disease and insect control since its inception.

is report summarizes the performance of the maturing trees

from 2011 through 2013.

Materials and Methods

Trees of the apple scab resistant cultivars ‘Redfree’, ‘Crimson

Crisp’ and ‘Enterprise’ on B9 rootstocks were planted in April

2007 in three rows. Each row contained four blocks of three

trees of each cultivar per block with border trees at both ends

of each row and a guard row of trees on both sides of the group

of three research rows. Trees were set at a 6 ft by 18.5 ft spacing

within and between rows, respectively. ere are a total of 215

trees on about a half acre. Trickle irrigation was installed soon

after planting. A grass groundcover was established between

rows, and the ground beneath the rows was periodically tilled

with a Weed Badger 4000-NST (Weed Badger Division, Marion,

ND 58466).

Each tree was staked to a metal pole in year 1. Trees were

pruned to a slender spindle until year 6 (2012). However, lower

branches were often pulled downwards due to their fruit load,

impeding weed tillage. us, in 2012 a low wire at 3 ft above the

ground was attached to the poles, and the lower branches and

trickle irrigation line were tied to it. In 2013, an upper wire was

attached at 5.5 ft above the ground and upper branches were

tied to it.

Trees were fertilized with Nature Safe fertilizer at 100 lb

N/A each spring and were sprayed with organically-approved

compounds which were reported and/or recommended for

controlling the major apple diseases and insect pests (Table 1).

Fruit were thinned by spraying a mixture of lime-sulfur plus

Organocide (fish oil/sesame oil), each at 2.5% v/v, at petal fall

across cultivars, followed by hand thinning.

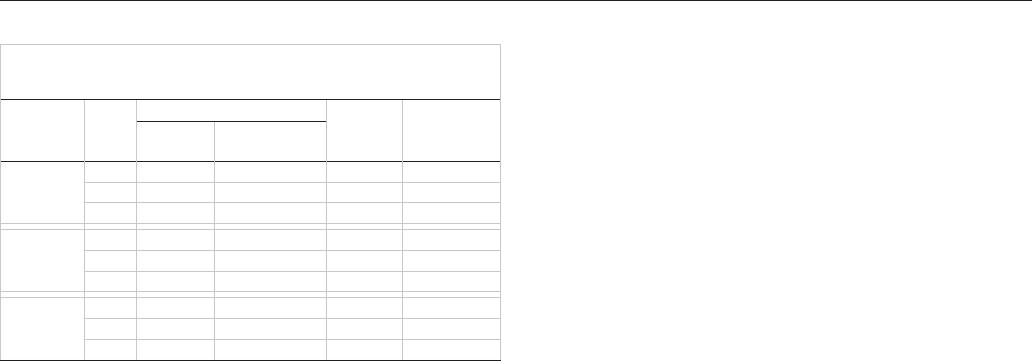

Table 1. Organically approved compounds used for disease and insect

control, 2011-2013.

Problems

Diseases Compounds

reblight xed copper, streptomycin

apple scab, rusts, fruit rots,

sooty blotch, yspeck, leaf

spots, powdery mildew

Microthiol sulfur, lime sulfur, xed

copper, Regalia, Kaligreen

Insects Compounds

scale dormant oil

plum curculio, codling

moth, oriental fruit moth

Entrust, Surround, Carpovirusine, Neem

oil, codling moth pheromone mating

disruption lures

aphids, tarnished plant

bugs, leafrollers, stink bug

pyrethrum

dogwood borers nematodes (Heterohabditis

bacteriophora)

12

TREE FRUITS

e total and marketable yield and fruit count were recorded

for each tree. Fruit were considered marketable if they had no

significant disease or insect injury and were of acceptable size.

A spring freeze during bloom in 2012 reduced the expected

crop.

Results and Discussion

Total yield. e total yields included all fruit on the tree,

whether marketable or not. e total 2013 yields were higher

than those in 2011 and 2012. However, the lighter crop in 2012

due to the spring freeze likely contributed to a greater bloom

intensity in 2013 and thus a higher yield than in the previous

years. Enterprise had the greatest yield each year. Redfree yield

increased appreciably in 2013, while that of Crimson Crisp

did not.

Marketable yield. A portion of the crop was not market-

able each year, due to both insect and disease damage. Redfree

yielded the highest marketable percent of the total crop, around

70%. Crimson Crisp and Enterprise ranged from 40-55% and

42-48% over the three-year period, respectively. It is worth not-

ing that Redfree was the first cultivar harvested each season, in

early August, with the shortest time for exposure to diseases and

insects, and had the highest marketable yield each year. e data

suggest that disease resistant cultivars with earlier harvest dates

like Redfree may be more appropriate for organic production.

e marketable yields of Crimson Crisp and Enterprise must be

appreciably increased to make organic production with them

economically sustainable.

Fruit size. Fruit size was comparable within each cultivar in

2011 and 2013. However, the thinning effect of the spring freeze

led to a light crop with larger fruit for Redfree and Enterprise in

2012. Generally, Enterprise was the largest, followed by Crimson

Crisp, then Redfree.

It is clear that economically significant marketable organic

apple yields will not be easy to achieve, but critical limiting fac-

tors have been identified. As expected, the major limitations are

diseases and insects. Brown marmorated stink bug movement

into the area is expected to present problems as currently there

are no organically certified pesticides that effectively control

this insect. Fruit thinning with lime sulfur/fish+sesame oil plus

hand-thinning was successful. Weed management under the

trees with periodic, shallow tillage was successful once the lower

limbs were pulled up and away from the path of the equipment.

However, vole damage has continued to be a problem despite

cultivation to remove habitat. Fertility was sufficient. e proj-

ect will continue for a few more years to determine if total and

marketable yields can be increased as the trees age and with

modified and/or new insect and disease control strategies.

References

Hinman, T. and G. Ames. 2011. Apples: Organic Production

Guide. National Sustainable Agriculture Information Ser-

vice, National Center for Appropriate Technology, 40 pp.

Acknowledgments

e authors would like to thank Delia Scott, Neil Wilson,

and Nicole Ward for their hard work and assistance in this

project.

Funding for this project was provided by a Kentucky Department of

Agriculture Specialty Crop Block Grant.

Table 2. Yield per tree and fruit size (mean ± SE) of organically-grown

apples at the Horticultural Research Farm, Lexington, Kentucky, 2011-

2013.

Cultivar Year

Yield (lbs/tree)

All MarketableTotal

Marketable

(% of total)

Redfree 2011 4.9 ± 1.1 3.6 ± 0.7 (73) 4.1 ± 0.1 4.3 ± 0.1

2012 3.0 ± 0.5 2.0 ± 0.4 (67) 6.6 ± 0.3 7.0 ± 0.4

2013 13.4 ± 1.5 9.9 ± 1.2 (74) 4.1 ± 0.1 4.2 ± 0.1

Crimson

Crisp

2011 4.7 ± 0.9 1.9 ± 0.5 (40) 5.2 ± 0.2 5.7 ± 0.2

2012 7.1 ± 1.0 3.3 ± 0.5 (46) 4.8 ± 0.2 5.4 ± 0.2

2013 8.0 ± 0.7 4.4 ± 0.4 (55) 5.2 ± 0.1 5.4 ± 0.1

Enterprise 2011 9.1 ± 0.9 4.4 ± 0.7 (48) 6.8 ± 0.2 7.3 ± 0.2

2012 8.1 ± 1.1 3.5 ± 0.6 (43) 9.0 ± 0.4 9.4 ± 0.4

2013 18.4 ± 1.4 7.8 ± 0.8 (42) 7.7 ± 0.3 7.8 ± 0.2

13

SMALL FRUIT AND GRAPES

The ‘Prime-Jan®’ and ‘Prime-Ark®45’ Thorny

Primocane-Fruiting Blackberry Trial

Kirk W. Pomper, Jeremiah D. Lowe, and Sheri B. Crabtree, College of Agriculture, Food Science, and Sustainable Systems, Kentucky State University;

John R. Clark, Department of Horticulture, University of Arkansas; and John G. Strang, Department of Horticulture, University of Kentucky

Introduction

e climate of Kentucky is well-suited for blackberry pro-

duction Blackberry plants are unusual among fruit crops in

having perennial root systems but having biennial canes. ere

are two cane types: primocanes, or first year canes, which are

usually vegetative, and floricanes, which are the same canes and

flower and produce fruit the next growing season. Floricanes

then die after fruiting and need to be removed. Primocane-

fruiting blackberries can produce two crops per year, with a

normal summer crop (floricane) and a later crop on the current

season primocanes. Primocane-fruiting blackberries flower and

fruit from mid-summer until frost, depending on temperatures,

plant health, and location. Growers can reduce pruning costs by

mowing canes in late winter to obtain a primocane crop only.

is also provides anthracnose, cane blight and red-necked cane

borer control without pesticides. Relying only on a primocane

crop also avoids potential winter injury of floricanes.

e thorny primocane-fruiting blackberry varieties, ‘Prime-

Jim®’ and ‘Prime-Jan®,’ were released by the University of Arkan-

sas in 2004 (Clark et al., 2005; Clark, 2008). In Kentucky trials,

‘Prime-Jan®’ has higher yields and larger fruit than ‘Prime-Jim®’.

‘Prime-Ark®45’ was recently released for commercial produc-

tion, but has not been tested in Kentucky (Clark and Perkins-

Veazie, 2011). Fruit size and quality of primocane-fruiting

blackberries can be affected by the environment. Summer

temperatures above 85°F can greatly reduce fruit set, size and

quality on primocanes. is results in substantial reductions

in yield and fruit quality in areas with this temperature range

in summer and fall (Clark et al., 2005; Stanton et al., 2007). e

objective of this study is to compare yields and fruit quality of

‘Prime-Ark®45’and ‘Prime-Jan® under Kentucky growing condi-

tions. Here we report the results of the trial in its third year after

establishment.

Materials and Methods

In April 2010, plants of the commercially available, thorny,

primocane-fruiting cultivars ‘Prime-Jan®’ and ‘Prime- Ark®45,’

were planted at the KSU Research and Demonstration Farm,

in Frankfort, Kentucky. Plants were arranged in a randomized

complete block design, with four blocks, including five plants

of each cultivar per block (total of 20 plants of each cultivar) in

a 10 foot plot. Spacing was two feet between each plant, and

five feet between groups of five plants, with each row 125 feet

long. Rows were spaced 14 feet apart. is trial was planted on

certified organic land and managed with organic practices fol-

lowing the National Organic Program standards. Weeds were

controlled by placing a six- to eight-inch-deep layer of straw

around plants, adding straw when necessary, and hand weed-

ing. Plants were irrigated weekly with t-tape laid in the rows.

In 2013, dormant canes were mowed in mid-March. erefore,

only primocane fruit were harvested in 2013. Primocanes began

producing fruit in late July. ey were harvested each Monday

and ursday until a killing frost of 26°F on October 25.

Results and Discussion

Primocane fruit were harvested from late July until frost

in late October (Table 1). Primocane production of ‘Prime-

Ark®45’ out yielded ‘Prime-Jan®’ by almost a threefold margin,

and berry size was also larger for ‘Prime-Ark®45.’ Growing

conditions in 2013 were mild compared to 2012; there were

40 out of 122 days with a high temperature above 85°F from

June through September. e average high in July was 81.9°F.

In June 2012 there were three days that the temperature was

over 100°F and only five days with high temperatures below

85°F. e lower temperatures in 2013 led to a higher yield for

both varieties compared to 2012. e University of Arkansas

Blackberry Breeding Program already recommends that pro-

ducers plant ‘Prime-Ark®45’ instead of ‘Prime-Jan®,’ due to the

superior shipping quality of the firmer fruit of ‘Prime-Ark®45.’

Year-to-year yield characteristics will need to be further evalu-

ated; however, the 2013 data suggests that in Kentucky ‘Prime-

Ark®45’ yields should be higher than ‘Prime-Jan®’ and similar to

some floricane varieties. ‘Prime-Ark®45’ should be considered

by commercial growers interested in producing primocane

fruiting blackberries.

Table 1. Yields and berry weights for

‘Prime-Jan®’

and

‘Prime-

Ark®45’

from the University of Arkansas Blackberry Breeding

Program at the Kentucky State University Research Farm, 2013.

Selection

Fruit Weight

(g)

Yield

(lb/acre)

Harvest

Dates

‘Prime-Jan®’ 3.50 b

z

3305 b 7/18-10/22

‘Prime-Ark®45’ 4.69 a 8812 a 8/1-10/22

Z

Numbers followed by the same letter are not signicantly dierent

(Least Signicant Dierence P ≤ 0.05)

Literature Cited

Clark, J.R., J. N. Moore, J. Lopez-Medina, C. Finn, P. Perkins-

Veazie. 2005. ‘Prime-Jan’ (‘APF-8’) and ‘Prime-Jim’ (‘APF-12’)

Primocane-fruiting Blackberries. HortScience, 40:852-855.

Clark, J.R. 2008. Primocane-fruiting Blackberry Breeding.

HortScience, 43:1637-1639.

Clark, J.R. and P. Perkins-Veazie. 2011. ‘APF-45’ Primocane-

fruiting Blackberry. HortScience April 2011 46:670-673.

Stanton, M.A., J.C. Scheerens, R.C. Funt, and J.R. Clark. 2007.

Floral Competence of Primocane-fruiting Blackberries

Prime-Jan and Prime-Jim Grown at ree Temperature

Regimens. HortScience, 42: 508-513.

14

SMALL FRUIT AND GRAPES

Organic Grape Cultivar Evaluation Trial in Kentucky

Jeff Wheeler, Sean Lynch, Kristi Durbin, and Patsy Wilson, Department of Horticulture

Introduction

Little if any grape acreage is dedicated to organic produc-

tion in Kentucky largely due to climatic conditions conducive

to recurring pest problems during the growing season. Grape

growers have expressed interest in organic production; however,

there are limited resources and recommendations for this type

of production system. Although organic grape production

methods have been developed in other regions, they have not

yet been tested under the climatic conditions of Kentucky. is

project has been initiated to study the challenges and limita-

tions to organic grape production in Kentucky and attempts

to identify crop protection strategies to maximize vineyard

outputs and vine health.

Materials and Methods

Two identical 0.5-acre experimental blocks were planted in

a randomized complete block design in the spring of 2011. One

block was treated with only OMRI-certified products (organic

block), while the other block (conventional block) received

a spray program consisting of non-OMRI-certified products

currently used to control vineyard pests in most commercial

Kentucky vineyards. Cultivars used in this experiment were

chosen due to their reduced susceptibility to black rot and tol-

erance to sulfur-based fungicides traditionally used to control

powdery mildew in organic production systems. Initial vineyard

site preparation consisted of spading a 4-foot-wide area directly

under each vine row, while allowing natural vegetation to serve

as a ground cover in the row middles. Immediately following

spading in the spring of 2011 vines were established at a vine-

row spacing of 10 feet between rows and 8 feet within each row.

Vines were trained to a 6-foot-high bilateral cordon training

system during the 2011 and 2012 seasons. All but the strongest

cane developed during the 2011 season was removed during

dormant pruning in March 2012 with this cane serving as the

newly established vine trunk. e two strongest shoots arising

from this newly established trunk were trained to the fruiting

wire in 2012.

Herbicides were used to control weeds in the conventional

block; mechanical tillage was used to control weeds in the or-

ganic block using a Weed Badger. Two applications of glyphosate

were applied as an in-row banded spray to the conventional

block in both May and July to prevent the herbicide spray from

contacting the vine foliage; grow tubes were applied around

each vine immediately before spraying and were then removed

the following day. Five tillage passes per year were required to

adequately control weeds directly under each vine row of the

organic block. Although more passes were required to control

weeds in the organic block, this block did not require the appli-

cation or removal of grow tubes used in the conventional block,

thus resulting in a significant savings in both labor and materi-

als required to control in-row weeds. Weed control through

mechanical cultivation generally resulted in a more uniform

and pleasing appearance; the herbicide application appeared

scorched and less uniform. Fertilization was not necessary in

either the conventional or organic grape planting.

In order to reduce vine stress during initial vineyard es-

tablishment, all flower clusters were removed as soon as they

appeared in both 2011 and 2012. Cluster thinning was done

shortly after fruit set in 2013. Vines showing sufficient vigor

were allowed to carry one cluster per shoot on shoots derived

from canes tied to fruiting wire.

Results and Discussion

Between treatment blocks there were few differences in

vine vegetative vigor when considering either average shoot

length or average number of nodes per shoot in 2011. After the

first vintage, the average length of the newly established trunk

measured 43 inches at dormant pruning in both the organic

and conventional blocks. Differences in vine vigor were more

apparent during the 2012 growing season with organically

treated vines appearing to have significantly higher vigor than

the vines in the conventional block. is increase in vine vigor

allowed for nearly full establishment of the fruiting wire, while

many vines in the conventional block failed to completely fill

the same space. Differences in vine vigor during the 2012 season

can likely be attributed to the effectiveness of the mechanical

weed control as compared to the herbicide control used in the

conventional block.

Improved vine vigor and vine size expressed by vines in the

organic block during the 2012 season should have resulted in a

larger yield in 2013, the third growing season. However, due to

above average spring and summer rainfall, fruit yield was sub-

stantially limited by black rot infections that occurred on fruit

in the organic block during the 2013 growing season (Tables 1

and 2). Although harvested fruit from the conventional block

expressed marked reductions in cluster rot incidence and sever-

ity, vines were less vigorous than vines in the organic block and

required higher level of cluster thinning which reduced the total

number of clusters and total yield per vine (Tables 1 and 2).

Fungicides were applied prophylactically to the Conven-

tional vines during the 2011-2013 seasons, according to the

protocols established in the Midwest Commercial Small Fruit

and Spray Guide (ID-94). No fungicides were applied to vines

located in the organic block in 2011-2012; copper and sulfur-

based fungicides were used to control powdery and downy

mildew in 2013. ere were no visual signs of fruit or foliar

diseases on vines planted in the conventional block during the

2011-2013 seasons (Table 3). Likewise, there were no significant

signs of foliar disease observed in the organic block during the

relatively dry seasons of 2011 and 2012 (Table 3). During the

2013 season frequent early rains resulted in commercially unac-

ceptable levels of black rot infections on fruit of several cultivars

planted in the organic block including Traminette, Villard blanc,

Mars, Noiret, Corot Noir, and Valvin Muscat (Table 2). Less

15

SMALL FRUIT AND GRAPES

black rot was observed on cultivars: Brianna, Cayuga White,

Edelweiss, Vanessa, and Villard Noir; however, fruit damage

caused by June beetles on these cultivars was substantial (Table

2).

is study has shown the potential advantages of using

organic production practices during establishment of disease

resistant cultivars adapted to the climate of Kentucky. Although

there was a limited need for fungicide application to treat com-

mon foliar diseases during the relatively dry 2011-2012 seasons,

control of foliar and fruit diseases was less than ideal on some

vines receiving organic fungicide treatments in the wet 2013

vintage. Of the cultivars used during this experiment, Brianna,

Cayuga White, Edelweiss, Vanessa, and Villard Noir appear to

be the most promising cultivars for organic grape production in

Kentucky. Further investigation will need to be done to monitor

the long-term performance of such cultivars to determine the

economic potential these may have for Kentucky vineyards.

Table 1. Yield components for the 2013 organic winegrape cultivar

trial, UK Horticulture Research Farm.

Cultivar/

Rootstock

Harvest

Date

Yield per

Shoots

Per

Foot of

Cordon

3

%

Culled

Clusters

4

Cluster

Weight

(lb)

Acre

1

(tons)

Foot

2

(lb)

Organic

Brianna

*

08/07 0.2 0.1 3.7 - 0.12

Cayuga

*

08/26 2.8 1.3 3.4 69 0.32

Corot Noir 09/06 1.3 0.7 3.6 85 0.22

Edelweiss

*

08/07 0.3 0.1 3.6 - 0.14

Mars 08/16 0.0 0.0 4.1 100 -

Noiret 08/19 0.0 0.0 3.7 100 -

Traminette/101-14 09/25 0.0 0.0 3.9 100 -

Valvin Muscat/5C

*

09/25 0.0 0.0 4.3 100 -

Vanessa 08/16 0.0 0.0 3.3 100 -

Villard Blanc 09/25 0.0 0.0 4.2 100 -

Villard Noir

*

09/07 0.7 0.5 3.7 73 0.28

Conventional

Brianna

*

08/07 0.5 0.3 3.7 - 0.17

Cayuga

*

08/15 1.2 0.8 3.5 17 0.67

Corot Noir 09/06 1.4 0.8 3.7 5 0.62

Edelweiss

*

08/06 0.7 0.5 3.9 - 0.38

Mars 08/13 1.0 0.9 4.1 45 0.48

Noiret 09/16 0.8 0.5 4.2 2 0.48

Traminette/101-14 09/06 0.4 0.5 5.0 38 0.40

Valvin Muscat/5C

*

- - - 4.3 - -

Vanessa 08/16 0.0 0.0 3.2 100 -

Villard Blanc 09/17 1.5 1.1 4.7 0 0.73

Villard Noir

*

09/20 1.0 0.7 4.0 16 0.49

1

Yield per acre calculated using 8ft x 10ft vine/row spacing, with 545 vines

per acre.

2

Total yield divided by the total length of cordon = yield per linear foot of

cordon.

3

Total number of shoots divided by the total length of cordon = shoots

per linear foot of cordon.

4

Percentage of harvested clusters having ≥ 30% damage

*

Guard row varieties

Table 2. Fruit damage rating August 21st, 2013, organic cultivar

trial, UK Horticulture Research Farm.

Cultivar

Black Rot June Beetle

Instance

1

Severity

2

Instance

1

Severity

2

Cayuga 10 20 18 58

Corot Noir 93 38 30 36

Traminette/101-14 100 98 2 8

Valvin Muscat/5C 98 98 0 0

Villard Blanc 100 88 2 9

Villard Noir 11 9 20 27

1

Instance: Percentage of all clusters with any amount of damage

2

Severity: Percentage of damage on individual clusters

Table 3. Foliar disease rating September

28th, 2013, organic cultivar trial, UK

Horticulture Research Farm.

Cultivar Severity

1

Percentage

2

Organic

Corot Noir 1.8 2.0

Mars 2.4 3.9

Noiret 1.7 1.5

Traminette 1.1 1.4

Vanessa 2.4 3.7

Villard Blanc 1.0 1.0

Conventional

Corot Noir 1.0 1.0

Mars 1.5 1.0

Noiret 1.0 1.0

Traminette 0.5 0.5

Vanessa 1.5 1.5

Villard Blanc 1.0 1.0

1

Severity: 0 to 5 (O = No Damage à 5 =

Leaves Completely Damaged (chlorotic/

necrotic))

2

Percentage: 0 = 0%, 1 = 1-25%, 2 = 26-

50%, 3 = 51-75%, 4 = 76-99%, 5= 100%

16

SMALL FRUIT AND GRAPES

Leafhoppers Associated with Newly Established

Primocane Blackberry and Raspberry Plantings in Central Kentucky

John D. Sedlacek, Jeannie M. Haak, Karen L. Friley, Kirk W. Pomper, Jeremiah D. Lowe and Sheri B. Crabtree, College of Agriculture, Food Science, and

Sustainable Systems, Kentucky State University

Introduction

Growing blackberries and raspberries can be profitable in

Kentucky due to the long summers, warm temperatures and

the demand for locally produced fruit. One of the limiting

factors for high yields is insect pest damage. Some insects and

mites that damage foliage include leafhoppers, spider mites,

raspberry aphids, leaf rollers, climbing cutworms, blackberry

psyllid, western winter moth, raspberry sawfly, stink bugs, scale

insects, white flies, and thrips (Pritts 1991).

Leafhoppers (Hemiptera: Cicadellidae) damage the plants

by feeding on their leaves, causing shoot tip distortion, leaf

margin curling, and yellowing leaves. Leafhoppers can also be

vectors of plant pathogens, causing a variety of diseases. Rubus

stunt is a leafhopper-transmitted disease found in wild and

cultivated Rubus plants in Europe, the Middle East, and Russia

(Converse 1991). It has not been found in North America, but

the primary leafhopper vector Macropsis fuscula occurs in

the western United States (Converse 1991).

Kentucky State University (KSU) horticulture personnel

are examining the suitability of newly released primocane

fruiting blackberries and raspberries in central Kentucky. is

study quantifies leafhoppers during a five-week period in mid-

summer 2012 in central Kentucky.

Materials and Methods

Bushes of six varieties of blackberry and raspberry were

obtained from Indiana Berry and Plant Company (Plymouth,

Indiana). e varieties were Black Magic™, Caroline, Fall Gold,

Heritage, Nantahala, and Prime Ark 45

®

. ese plants were given

to growers in early June at five sites in three Kentucky counties:

Fayette, Franklin, and Shelby. All varieties were also planted

and sampled at the KSU Research Farm (Frankfort, KY). Each

site had 15 plants of each variety except the Montessori school

which had 10 total plants.

Insects for sampling were caught on sticky traps. irty-one

6 x 6 inch yellow sticky traps were stapled to tobacco stakes close

to the main cane of the blackberry or raspberry plants. Traps

were removed from stakes and placed into one gallon plastic

storage bags and labeled with location name, sample number,

date, and variety. ey were then placed into a freezer for a

minimum of 24 hours to kill live insects. Samples were taken

weekly at each site and each variety at each location.

Traps were inspected with a Bausch & Lomb lighted mag-

nifier and Nikon binocular dissecting microscope. Species

and species groups (i.e., unidentifiable species within a genus)

were assigned a reference number, counted, and recorded.

Dr. Paul Freytag, Professor Emeritus, University of Kentucky

Department of Entomology, was consulted concerning species