CFC / ICAC / 11 Project Technical Report on Research Activities Page 177

C.5. Effects of relative humidity on the spinning process and yarn quality

C.5.1. Objective

It is possible, through measurement of the stickiness of raw cotton, to predict the disruption

that may occur during spinning. Now, this experiment is designed to answer the question:

what is the effect of relative humidity on the spinning process and the quality of the yarn ?

C.5.2. Materials and methods

Seven cottons were selected from the 24 cottons spun at ITF during the industrial spinning

study to cover a range of stickiness. These cottons were obtained from the Laroche mix. One

spinning test was performed for each cotton with two types of spinning – open-end or rotor

spinning (OE) and ring spinning (RS) in three relative humidity conditions (40, 45, 55%).

For industrial carded varieties of cotton, the procedure is as follows: first opening and

blending of cotton, then carding, condensation of the web in a sliver, drawing steps, flyer and

spinning. As far as the micro-spinning is concerned, the previous procedure was adapted in

line with the quantity of the cotton fibers to be spun (Frydrych and Dréan, 2000).

The micro-spinning stages for an amount of cotton ranging from 50 to 500g are shown in

Figure C-1.

Cirad uses Platt micro-spinning equipment which consists of a mini-card, a drawing frame

and an eight-spindles spinning frame with double drawing, as well as six Suessen open-end

rotors.

C.5.2.1. General micro-spinning steps

The full set of spinning tests were to be conducted in three steps (Figure C-1).

C.5.2.1.1. First step: opening and carding

Fiber preparation consisted of blending, cleaning, disentangling fibers. It could be split into

the two following stages:

- cotton opening and blending on the Cirad cotton opener for samples of 50 g and over;

samples of 250 g to 500 g were split into 5 parts of 50 or 100g.

- carding operation provided the cleaning, disentangling and paralleling of fibers while

eliminating a part of the neps and short fibers. Depending on the starting weight of the

sample, i.e. 50 or 100 g, the outgoing web of a weight of 5g/m² was taken by the cylinder,

with respective lengths 0.77 m or 1.57 m. In our case, the 5 sub-samples were carded into

5 fleeces.

C.5.2.1.2. Second step: drawing

The drawing consisted in passing the fibrous flow (fleece or sliver) between four pairs of

pressing cylinders, driven at different tangential speeds. In all cases, it was necessary to

perform three drawing operations. The first passage changed the card outgoing fleece into a

sliver. The two other operations correspond to those performed in an industrial plant. Two

methods:

- sliver from the sample of 50 g is collected on a drum;

- sliver from the sample of 250 g and over is collected in cans.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 178

In our case, we ran our 5 fleeces of 100 g on the first pass of the drawing frame to produce 5

slivers. These 5 slivers altogether (for a doubling) fed the second passage on the drawing

frame to produce 10 slivers. For the third passage, the 10 slivers altogether (for a doubling)

fed the drawing frame to produce 4 cans (one can per spinning position for both OE and RS

spinning).

C.5.2.1.3. Third step: ring spinning and rotor spinning

Spinning consists of winding the yarn on a support. The two main types were being used: ring

spinning (RS) and rotor spinning (OE).

The micro-spinning methodology for the relative humidity study is described in

Figure C-2.

For this study we used methodology based on 500 g of cotton per test, with the two types of

spinning (OE and RS). This methodology was duplicated for each of the three ambient

conditions: 40%RH and 27 °C, 45

%

RH and 22 °C; 55

%

RH and 27 °C.

During industrial spinning at ITF, eight kilograms of fibers per cotton were taken from the

Laroche opening machine for the seven selected cottons. One kilogram from each was

sampled for each relative humidity condition, 40%, 45%, 55% per type of spinning.

For each humidity condition and for each cotton, 10 samples of 100 g were worked out per

spinning. Different yarn counts were performed depending on the spinning process: 20 tex for

the ring spinning process, and 27 tex for the open-end process.

The randomization designated work at 45

%

humidity first, then at 55

%

, and finally at 40

%

RH.

The order in which the seven cottons were spun in each humidity experiment was randomly

organized.

The organization of this experiment is illustrated in

Figure C-2 and discussed below.

C.5.2.1.4. Opener

Twenty samples of each cotton (100 g x 10 for RS, 100 g x 10 for OE) were prepared one

after the other. No notes were taken since this was simply an opening / blending operation of

the raw material.

C.5.2.1.5. Mini-card

Stickiness level was evaluated during the carding on the small cylinder (perimeter = 0.77m).

The evaluation was made fleece after fleece, and also taking care to the time. Four grades of

stickiness were defined:

- grade 1; non sticky, no deposit on the 2 cylinders (upper and lower);

- grade 2; slight stickiness; some deposits, some rising, possible rolling up;

- grade 3; medium stickiness; rising and many deposits, rolling up;

- grade 4; high stickiness; high rising, many deposits, high rolling up, web break.

The evaluation time was up to rolling-up while recording the time required to get them. Then,

in case of sticky cottons, after 3 rolling up, the cotton was considered as highly sticky, and the

upper cylinder of the card was removed to continue the carding process of the remaining

cotton sample.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 179

The outcome products at the card level are 20 fleeces (100 g each, Slide C-1). In order to

produce two replicates of RS and OE yarns, this set of 20 fleeces is divided into 2 groups of

10 fleeces, each group being processed by a doubling of 5 fleeces. Thus 4 groups of fleeces

were processed on the drawing frame: 5 fleeces for RS, repetition 1; 5 fleeces for RS,

repetition 2; 5 fleeces for OE, repetition 1, 5 fleeces for OE, repetition 2 respectively.

C.5.2.1.6. Drawing

For each spinning repetition, 5 fleeces were transformed to form sliver (Slide C-2 to Slide

C-4). The drawing roller was cleaned between each 500 g or following accumulation of

stickiness which led to breakage of the sliver. All the incidents, interventions concerning the

rolling-up were noted. The slivers from each repetition were collected in 4 cans for the ring-

spinning and 2 cans for the open-end spinning.

C.5.2.1.7. Ring spinning

The four slivers of stickiness for each repetition were spun on 4 independent spindles (Slide

C-5).

Each spindle produced 8 cops (1 cop at each doffing).

Observations made during spinning, and mainly at the back drawing of the spinning

concerned:

- spinning disruptions or breakages (induced or not by stickiness);

- presence or absence of sticky points deposited on the back draught roller (in some case,

we also noted deposits on the front roller) causing the fiber to wrap around the roller;

- manual interventions or cleanings to prevent spinning from being interrupted.

C.5.2.1.8. Open-end

Two slivers were used per repetition. Each sliver fed one rotor and gave 1 bobbin per

repetition. Observations made during spinning concern:

- number of spinning disruptions or yarn breakages (induced or not by stickiness)

- number of rotor cleanings.

C.5.2.2. Yarn quality characterization

C.5.2.2.1. UT3 evenness tester

The following evenness tester machine settings were used:

- RS: speed 100 m/min, thin (-50%), thick (+50%), neps (200%), slot 1 (20 tex)

- OE: speed 100 m/min, thin (-50%), thick (+50%), neps (280%), slot 2 (>21 tex)

The tests were conducted as follows:

- Yarn tests in ring spinning

Every cop produced was UT3 tested (i.e. 64 cops * 250 m/cops = 16000 m tested).

- Yarn in open-end

2 repetitions x 2 bobbins x 1 km x 4 measurements, i.e 16000 m.

- Detailed analysis of RS yarn: a detailed neps analysis was performed using a method

CFC / ICAC / 11 Project Technical Report on Research Activities Page 180

developed at Cirad to identify the different types of neps observed. During this measurement,

the evenness tester stops the flow of the yarn at the appropriate position so that every nep is

examined in detail through a magnifying lens under intense light and classified as seed coat

fragment, fiber neps, (entangled and sticky neps), fragments such as leaves or sticky neps.

Percentages obtained for each type of imperfection were adjusted to total neps on 1000 m to

obtain the number of neps per type of imperfection on 1000 m. This detailed analysis was

performed on 1/8th of the cops produced on 1000 m of yarn (first doffing of 4 cops per

repetition) for a total of 2000 m.

- Detailed analysis of OE yarn: the same method as for ring spun yarns was employed to

characterize the neps on OE yarn on 4 bobbins with 2 measurements (1000 m each) for a total

of 8000 m.

C.5.2.2.2. Tenacity using Tensorapid 3

Yarn strength took account of the yarn count as determined by UT3 measurement.

- Ring spinning

Only 3/8th of the 64 cops were tested on Tensorapid because testing time was long

(20 seconds per break, 40 breaks / cop) for a total of 960 breaks. The cops chosen

corresponded to the first, fourth and eighth produced at each single spinning position. Thus,

12 cops were tested per repetition.

- Open-end

Two bobbins * 2 repetitions x 40 breaks x 4 measurements = 640 breaks.

C.5.3. Results and discussion

C.5.3.1. Effect on the spinning process

C.5.3.1.1. At the card level

The figures below only show a fitted line if a significant relation was detected between the

measured criteria and the stickiness level of the given cottons.

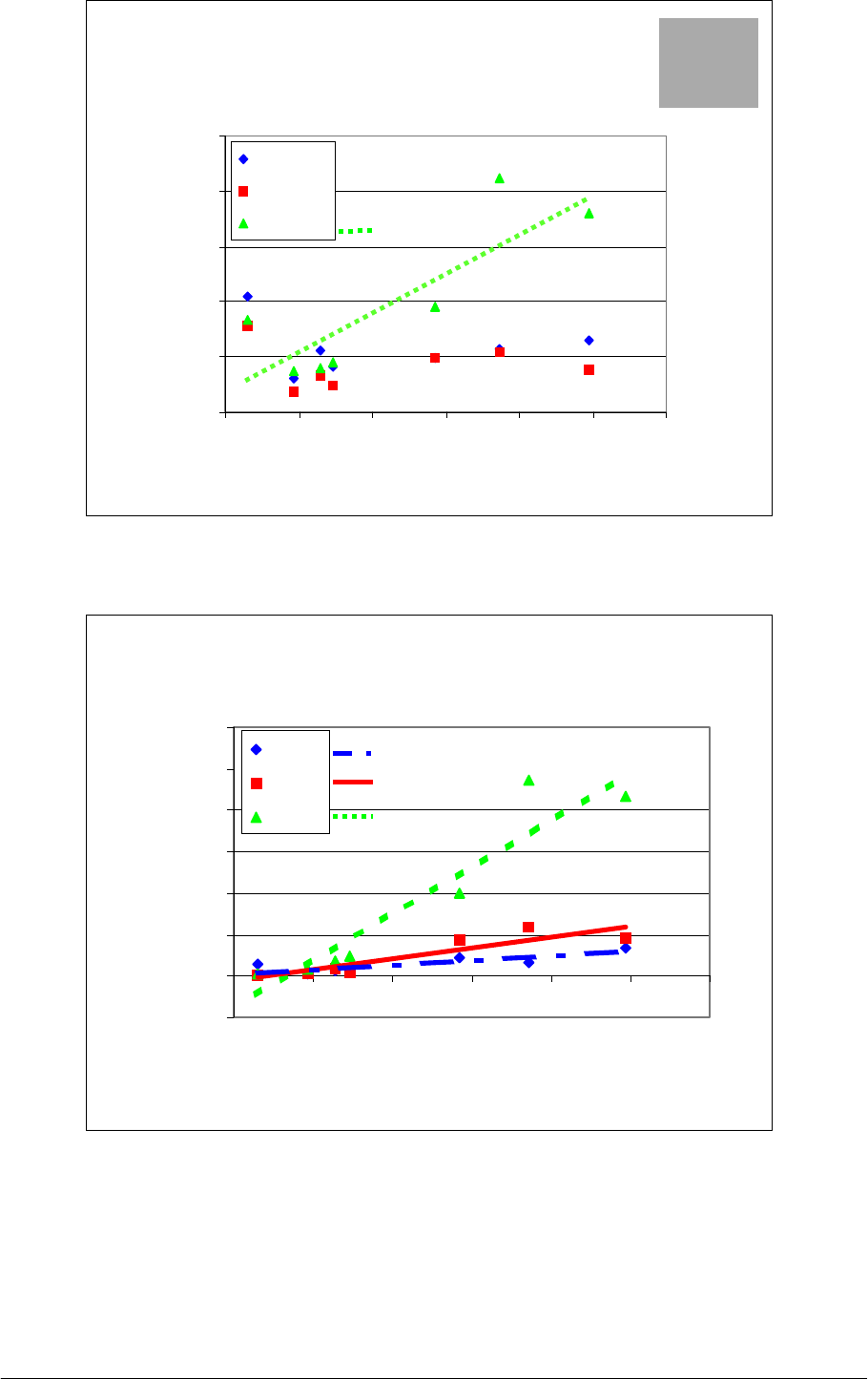

Figure C-3 shows that stickiness had a significant effect on the rolling-up at the card level

when RH was 45%, while no trend was noted at 55%RH since it appeared to bring immediate

troubles for any cotton stickiness level. None of the cottons caused disruption at 40

%

RH. A

saturation effect was noted in the number of rolling-up at 55%RH because the operating

procedure employed did not record any rolling-ups after the third occurence. Some examples

of the effect of stickiness at the card level are given in Slide C-6 to Slide C-9.

It should be noted that these results take account of the accumulation of stickiness

phenomena occuring for a complete set of 10 fleeces except when more than 3 rollings-up

occured.

As far as time till onset of rolling-up is concerned, the highest relative humidity levels (45

and 55% RH) were seen to have a significant effect, as illustrated in figure C-67. Any rolling-

up at 40% occurred after a very long time (as shown in figure C-66 for the most sticky

cotton).

C.5.3.1.2. At the drawing frame level

A significant relation was noted between the number of rollings-up and the stickiness level at

55%RH (Figure C-5). However, the number of interventions (where production did not need

CFC / ICAC / 11 Project Technical Report on Research Activities Page 181

to be halted, Figure C-6) and cleaning (the machine is stopped for this operation, Figure C-7)

on the drawing frame increased with stickiness as soon as the relative humidity increased.

Some stickiness-induced problems are shown in Slide C-10 and Slide C-11.

C.5.3.1.3. At the OE spinning level

A trend was noted between breakages and stickiness for the highest RH (Figure C-8), while

no significant relation was found concerning the cleaning of the machinery (Figure C-9).

It should be noted that cleaning operations were only performed after a breakage, and only if

a sticky deposit was observed in the rotor (Slide C-12 and Slide C-13).

C.5.3.1.4. At the Ring Spinning frame level

Figure C-10 shows the number of cleanings required to render the machine productive. These

cleanings were performed when yarn production was stopped (the yarn was broken) unless

this cleaning was required to maintain yarn production (for instance, when too many breaks

were observed in a short time due to stickiness accumulation).

At 40

%

RH, almost no cleaning was required to maintain production, whatever the stickiness

level of the raw cotton. At 45 and 55% RH, cleaning was required to maintain yarn

production.

The overall increase in the number of interventions, as a function of RH and stickiness levels

during these experiments on all machines we used, probably had an effect on the quality of

the yarn. Thus, the cleaning and intervention operations removed some potential irregularities

from the yarn. In other words, our interventions were performed to maintain yarn production,

but they also indirectly improved the final quality of the yarn. Thus, the yarn quality results in

this experiment were not only dependent on stickiness and RH% conditions but also on the

number of cleaning/interventions. We will have to take this into consideration when looking

at yarn quality results below.

C.5.3.2. Effect on yarn quality

Depending on the type of spinning (RS or OE), different categories of neps were counted on

the yarn by the evenness tester as defined in standards: neps 200

%

for RS yarns, and neps

280

%

for OE yarns.

C.5.3.2.1. Quality of Ring Spun yarns:

An analysis of variance of the results of this study was performed in a split-plot factorial

(1/2*3) design for the main yarn quality characteristics. The results are presented in Table

C-1. Data for the counts were assumed to follow a Poisson distribution because their

distribution should be even within the yarn because of the mixing process conducted while

spinning. Thus, to normalize their variance, these counts were transformed through a square

root calculation. However for clearer understanding of the results, the charts use raw and real

scale data.

Table C-1: Analysis of variance of the data collected in the RH experiment on RS yarns.

RH SUDAN YARN ANALYSIS, 3 HUMIDITIES, 7 COTTONS, Ring Spinning, 2 SETS

File: RH UT3 Title: RH SUDAN UT3

NUMBER of OBSERVATIONS: 84

DISPOSITIF DE L'ESSAI: SPLIT-PLOT 1/2

CFC / ICAC / 11 Project Technical Report on Research Activities Page 182

FACTEUR 1: 3 HUMIDITES 40% (40%), 45% (45%), 55% (55%)

FACTEUR 2: 7 COTONS 1 (AS02), 2 (AS09), 3 (AC1), 4 (AS04), 5 (AS10), 6 (AS20), 7

(AS05)

FACTEUR 3: 2 BLOCS BLOC 1 (B1 ), BLOC 2 (B2 )

CVM RAC.

THIN

RAC.

THICK

RAC.

NEPS

200%

Hairiness

Yarn

Elong.

Yarn

TEN.

Yarn

CV TEN.

Res.

Suspects

00022000

F Hum. 0,0056 0,0021 0,0056 0,0306 0,1501 0,0010 0,0111 0,0853

ETR 1 0,19 0,69 0,48 1,33 0,19 0,04 0,16 0,37

CV 1 (%) 0,8 2,5 1,3 4,2 3,1 0,8 1,3 2,8

F Cot. 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000

Int. H×C 0,0000 0,0012 0,0000 0,0000 0,0000 0,1042 0,1272 0,0273

ETR 2 0,23 1,19 0,86 1,22 0,06 0,10 0,29 0,78

CV 2 (%) 1,0 4,4 2,3 3,9 0,9 2,0 2,3 5,9

Gen.

Mean

23,05 26,95 37,25 31,28 6,11 5,21 12,53 13,21

40

%

45

%

55

%

23,75a

22,70b

22,72b

30,74 a

25,93 b

24,18 c

38,99 a

36,33 b

36,43 b

32,43 a

29,04 b

32,37 a

6,23

6,13

5,98

5,57 a

5,11 b

4,97 c

12,22 b

12,44 b

12,94 a

13,55

12,89

13,19

1 (AS02)

2 (AS09)

3 (AC1)

4 (AS04)

5 (AS10)

6 (AS20)

7 (AS05)

23,76b

24,13a

20,28d

23,64b

24,01ab

21,72c

23,84ab

29,32 bc

32,62 a

15,68 e

29,96 b

30,44 b

22,50 d

28,14 c

40,49 a

40,02 a

29,40 d

38,48 b

39,94 a

32,17 c

40,25 a

37,97 a

29,35 c

27,52 d

29,21 c

32,87 b

24,98 e

37,08 a

6,13 d

6,42 b

5,21 f

6,57 a

6,40 b

5,81 e

6,26 c

5,34 b

4,94 d

5,59 a

4,79 e

5,02 d

5,61 a

5,20 c

12,43 c

11,42 e

14,16 a

11,86 d

12,05 d

13,21 b

12,59 c

12,82 cd

14,14 ab

10,94 e

14,89 a

13,59 bc

12,34 d

13,75 abc

As stated in many publications, yarn quality is dependent upon fiber quality. In this study,

stickiness had difference effects on yarn quality depending on the relative humidity in the

spinning room. However, since most of the cottons used in the study were of similar quality,

most of the effects observed were considered to be due to stickiness. Nevertheless, care

should be taken when considering the results and a check should be performed to verify

whether the effect is due to stickiness or fiber quality parameters.

Relative humidity had a critical effect on yarn quality characteristics, and in particular by a

change in the evenness counting for irregularities.

The figures in Table C-29 illustrate the relations described. A fitted line is only displayed in

the figures below if a significant relation exists between the measured criteria and the

stickiness level of the given cottons. In some figures, no significant relationship was detected

CFC / ICAC / 11 Project Technical Report on Research Activities Page 183

for any of the cottons, but one may appear to be highly significant for the cottons considered

to show ‘low to medium’ stickiness. In these cases, the fitted line were drawn for these

cottons. We give the analysis of variance results (drawn from Table C-1) in the upper right

hand corner of the picture.

Figure C-11 shows a significant increase in Thin places in the RS yarn spun using cottons

with a low stickiness level. For all humidity levels, the number of thin places showed a

similar trend toward saturation when stickiness exceeded 20 sticky points. However, it was

noted that more thin places occurred at lower humidities compared to other conditions.

Figure C-12 shows the relation the number of thick places plotted against RH% and

stickiness. The only significant relationship was noted at 55% RH between the number of

thick places and stickiness.

Figure C-13 shows that RH and stickiness had a significant impact on the number of neps

(200

%

) in the yarn. However, a significant interaction induced a greater sensitivity to

stickiness at higher humidity. It was also observed that the number of neps was higher when

slightly sticky cotton was spun at 40% RH compared to the results when the same cotton was

spun in 45 and 55% RH.

Moreover, a detailed analysis showed that stickiness increased the number of sticky neps

(Stk, Figure C-14, Slide C-14), and also the number of fiber neps at all RH values (F, Figure

C-15) under 45 and 55

%

RH conditions.

A significant relationship was noted solely between yarn strength and stickiness at 40

%

RH,

even though the pattern at other humidities was similar (Figure C-16). This trend can be

explained by the fact that stickiness induces irregularities that creates weak points in the yarn

(as well as seed coat fragments, Krifa, 2001). This can be proven by counting the seed coat

fragments present in the card fleeces (Figure C-17), where both counts (on yarn and on card

fleeces) follow the same trend.

Figure C-18 shows that the cotton which appeared to show little stickines contained many

seed coat fragments that significantly affect yarn strength. Thus, the trend observed in Figure

C-16 for the lower stickiness level cannot be considered as significant.

In most of the figures, a saturation effect was observed in the relations with stickiness. As

stated above, interventions were made during the experiment to allow yarn production (these

interventions were mainly performed for heavily contaminated cottons, Figure C-7 for

instance), but was assumed indirectly to improve yarn quality. This hypothesis cannot be

proven since it is impossible to predict what kind of defect we avoid by cleaning the spinning

frame. However, this assumption can be proven by looking at the relationships between the

main criteria (such as the number of thin and thick places and yarn strength) and stickiness:

when few interventions are required to spin (non sticky cottons), we observe significant

relations between the ‘yarn quality criteria’ and stickiness; as soon as the number of

interventions increases, the relation between ‘yarn quality criteria’ and stickiness becomes

non-significant and a saturation effect occurs.

The trend observed on the left of Figure C-16 does not continue to the higher level of

stickiness since interventions and cleaning were performed to allow yarn production. Thus,

we can assume that the number of irregularities was decreased artificially by the cleaning, and

the number of weak points in the yarn decreased accordingly. However, this assumption

should be checked using the new Tensorapid testing methodology and a new way to analyze

the dataset (empirical quantile / quantile plot method, Krifa, 2000, 2001). This methodology

can be used to analyze the interaction between fiber quality and/or contaminant on yarn

CFC / ICAC / 11 Project Technical Report on Research Activities Page 184

quality parameters.

C.5.3.2.2. Quality of Open End spun yarns:

An analysis of variance based on in the same design as for RS yarns was performed on the

data. The results of this analysis are given in Table C-1. Counting data are assumed to follow

a Poisson distribution because they should be evenly spread within the yarn because of all the

mixing processes conducted while spinning. Thus, to normalize their variance, these counts

transformed through a square root calculation.

Table C-1: Analysis of variance of the data collected in the RH experiment on OE yarns.

RH SUDAN YARN ANALYSIS, 3 HUMIDITIES, 7 COTTONS, Open End , 2 SETS

File: RH UT3 TITLE: RH SOUDAN UT3

NUMBER OF OBSERVATIONS: 84

DISPOSITIF DE L'ESSAI: SPLIT-PLOT 1/2

FACTEUR 1: 3 HUMIDITES 40% (40%), 45% (45%), 55% (55%)

FACTEUR 2: 7 COTONS 1 (AS02), 2 (AS09), 3 (AC1), 4 (AS04), 5 (AS10), 6 (AS20), 7

(AS05)

FACTEUR 3: 2 BLOCS BLOC 1 (B1 ), BLOC 2 (B2 )

CVM RAC.

THIN

RAC.

THICK

RAC.

NEPS.

280%

Hairiness

YARN

ELONG

YARN

TEN.

YARN

CV TEN.

Rés.

Suspects

22222002

F Hum. 0,1196 0,0287 0,0530 0,0037 0,2111 0,0093 0,6067 0,1901

ETR 1 0,75 0,55 0,85 0,41 0,66 0,23

,42

0,59

CV 1 (%) 4,8 11,1 9,0 5,3 12.2 ,3,2 4,2 5,6

F Cot. 0,0823 0,0124 0,0006 0,0000 0,1473 0,0000 0,0000 0,0000

Int. H×C 0,2529 0,0102 0,0014 0,0000 0,3342 0,0000 0,4137 0,2329

ETR 2 0,57 0,57 1,16 0,55 0,41 0,08 0,17 0,66

CV 2 (%) 3,7 11,4 12,2 7,2 7,5 1,1 1,8 6,4

Moy.

Gén.

15,49 4,99 9,46 7,73 5,47 7,20 9,90 10,41

40

%

45

%

55

%

15,16

16,12

15,20

4,39 b

5,94 a

4,65 b

8,40

9,72

10,26

7,43b

6,33c

9,42a

5,56

5,76

5,09

7,86 a

6,78 b

6,95 b

9,80

9,97

9,94

10,26

10,18

10,78

CFC / ICAC / 11 Project Technical Report on Research Activities Page 185

CVM RAC.

THIN

RAC.

THICK

RAC.

NEPS.

280%

Hairiness

YARN

ELONG

YARN

TEN.

YARN

CV TEN.

1 (AS02)

2 (AS09)

3 (AC1)

4 (AS04)

5 (AS10)

6 (AS20)

7 (AS05)

15,51

16,15

15,33

15,40

15,64

15,01

15,36

4,96 ab

5,83 a

5,21 ab

4,68 b

5,16 ab

4,50 b

4,64 b

10,77 a

9,54 ab

10,71 a

8,18 bc

9,57 ab

7,42 c

10,01 ab

9,80a

6,47c

9,39a

5,97cd

7,95b

5,31d

9.22a

5,53

5,22

5,13

5,73

5,71

5,42

5,54

7,43 c

6,69 f

7,19 d

6,99 e

6,76 f

7,76 a

7,57 b

9,89 c

9,19 e

11,06 a

9,39 de

9,52 d

10,21 b

10,06 bc

10,42 ab

11,41 a

8,59 c

11,10 a

11,44 a

9,84 b

10,06 b

The relationship was only significant at 55%RH (Figure C-19).

Figure C-20 shows a significant relationship between the number of thick places and

stickiness at 55

%

RH, while no significant relationship was noted for other RH conditions.

Figure C-21 shows a significant relationship between the number of neps and stickiness at

55%RH, while no significant relationship was noted for other RH conditions. The detailed

analysis of the neps present in the yarn provided more information concerning the type of

neps that had increased. Figure C-22 and Figure C-23 indicate that both fiber neps (F) and

sticky neps (Stk) contribute to the increase in the total number of neps in the OE yarn. It

should be mentioned that the number of neps also increased significantly with stickiness at

40%RH but to a lesser extent.

Figure C-24 shows that the cotton appearing as no sticky contains a lot of seed coat fragments

that significantly affects yarn strength. Thus the observed trend in Figure C-25 for lower

stickiness level cannot be considered as significant.

Similar trends were observed for yarn strength and stickiness relations in both OE and RS

yarns (Figure C-25). Again, stickiness increased the number of irregularities in the yarn,

causing an increase in the number of weak points, which decreased yarn strength.

Figure C-26 and Figure C-27 show the percentages of each type of nep in RS and OE yarns

respectively. Seed coat fragment contribute for a large part to the neps observed. Sticky neps

also increase as RH% increases.

C.5.4. Conclusion

As proven in the real-scale experiment, stickiness affects both productivity and quality

parameters. Thus, stickiness increases the number of cleanings and interventions during

spinning.

The data collected during this experiment also provide new information about the effect of

ambient conditions on yarn production. Stickiness increases the number of human

intervention, especially when spinning is conducted at high relative humidities. During this

experiment, our interventions were designed to allow yarn production to continue, and thus

affected some yarn quality parameters. Trends were nevertheless noted for most of the

parameters vs stickiness. The slopes of these relations are clearly affected by ambient

conditions during spinning.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 186

As a global conclusion, spinning under low humidity conditions will avoid most of the

problem induced by stickiness, even if some yarn quality parameters are affected by such

conditions.

Slide C-1: Mini-carding and collecting

system.

Slide C-2: Drawing-frame and collecting

system in cans.

Slide C-3: Feeding system on the 2nd pass

of the drawing frame.

Slide C-4: Drafting zone of the drawing

frame.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 187

Slide C-5: Ring spinning frame during a

stickiness observation phase.

Slide C-6: Example of a stickiness-

induced problem.

Slide C-7: Example of a stickiness-

induced problem.

Slide C-8: Example of a stickiness-

induced problem.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 188

Slide C-9: Example of a stickiness-

induced problem.

Slide C-10: Example of a stickiness-

induced problem.

Slide C-11: Rolling-up at the drawing

frame level.

Slide C-12: One sticky point on a rotor.

Slide C-13: One sticky point on a rotor.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 189

Slide C-14: Examination of a nep on the

evenness tester.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 190

OPENING CARDING

Raw cotton

A1 =50 g

or

A2 = 100 g

850g/m2

Fleece

280g/m2

A

1-- L=0.77m

A

2 --L=1.57m

560g/m2

A

1

or

A

2

A

1 -- L=0.38m

A

2 -- L=0.76m

260g/m2

A

1 -- L=0.77m

A

2 -- L=1.57m

DRAWING

Sample = 50 g = A1 case Sample = 250 g = A1 x 5 fleeces

Sample = 500 g = A2 X 5 fleeces

First drawing

Fleece transformed in sliver

Drawing ratio = 10.9

1 sliver

Sli

collected on

taken drum

5 slivers

Sli

collected in

cans

1 sliver

10 slivers

2500 tex

Count = 5450 tex

t 5450 t

Second drawing

count = 5450 tex

Third drawing

10

Doubling = 5

Drawing ratio = 10.9

Doubling = 10

Drawing ratio = variable

Count 2500 tex

sliver count

2300 tex to 3500 tex

x cans

sliver count

2300 tex 3500 tex

RING SPINNING

ROTOR SPINNING

1km < yarn length < 1.7 km

37 tex < count < 20 tex

Sample 250 g:

5km < yarn length < 9 km

37 tex < count < 20 tex

Sample 500 g: 5km < yarn length < 9 km

37 tex < count < 20 tex

Fleece Fleece

to

Figure C-1: Spinning procedure in a micro-spinning test.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 191

Cotton 1 to ...

Card

20 fleeces of 100 g each

5 * 100 g.

rep 1

5 * 100 g.

rep 2

5 * 100 g.

rep2

5 * 100 g.

rep 1

Drawing

frame

Drawing

frame

Drawing

frame

Drawing

frame

RS RS OEOE

Recording problems

Tensorapid : 480 breaks

UT3 : 8000 m

Detailed analysis : 1000m

Recording problems

Tensorapid : 320 breaks

UT3 : 8000 m

Detailed analysis : 4000m

Recording problems Recording problems

Tensorapid : 480 breaks

UT3 : 8000 m

Detailed analysis : 1000m

Tensorapid : 320 breaks

UT3 : 8000 m

Detailed analysis : 4000m

Figure C-2: Organization of the test from raw cotton to yarn testing.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 192

Humidity effect : card

0

10

20

30

40

50

60

70

0 102030405060

H2SD Mean

Rolling-up (nb)

c40%

c45%

c55%

Figure C-3: Effect of stickiness on rolling-up at the card level.

Humidity effect : card

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

0 102030405060

H2SD Mean

Time before rolling-up (h)

c40%

c45%

c55%

Figure C-4: Time to onset of rolling-up at different RH% values.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 193

Humidity effect : drawing frame

0

2

4

6

8

10

12

14

16

0 102030405060

H2SD Mean

Rolling-up (nb)

E40%

E45%

E55%

Figure C-5: Number of rollings-up at the drawing frame level vs stickiness.

Humidity effect : drawing frame

0

1

2

3

4

5

6

7

8

9

0204060

H2SD Mean

Interventions (nb)

E40%

E45%

E55%

Figure C-6: Number of interventions on the drawing frame vs stickiness.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 194

Humidity effect : drawing frame

0

2

4

6

8

10

12

14

16

0 102030405060

H2SD Mean

Cleaning (nb)

E40%

E45%

E55%

Figure C-7: Number of cleanings required on a drawing frame vs stickiness.

Humidity effect

0

5

10

15

20

25

30

0 102030405060

H2SD Mean

Breakage (nb)

OE 40%

OE 45%

OE 55%

Figure C-8: Breakages vs stickiness on the OE machine.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 195

Humidity effect

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

0 102030405060

H2SD Mean

Cleaning (nb)

OE 40%

OE 45%

OE 55%

Figure C-9: Number of cleanings on the OE machine vs stickiness.

Humidity effect

0

50

100

150

200

250

300

0 102030405060

H2SD Mean

Cleaning (nb)

RS 40%

RS 45%

RS 55%

Figure C-10: Number of cleanings on the RS machine vs stickiness.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 196

Humidity effect

0

50

100

150

200

250

300

350

0 102030405060

H2SD Mean

Thin places (nb/km)

RS 40%

RS 45%

RS 55%

HR : *

Cot : *

Int : *

Figure C-11: Number of thin places vs stickiness under different RH% conditions.

Humidity effect

0

50

100

150

200

250

300

350

400

450

500

0 102030405060

H2SD Mean

Thick places (nb/km)

RS 40%

RS 45%

RS 55%

HR : **

Cot : ***

Int : ***

Figure C-12: Number of thick places under different RH% conditions and stickiness levels.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 197

Humidity effect

0

500

1000

1500

2000

0 204060

H2SD Mean

Nb of neps200%/ km

Neps 40

Neps 45

Neps 55

HR : *

Cot : ***

Int : ***

Figure C-13: Number of neps under different RH conditions and stickiness levels.

Detailed analysis : Ring spun yarns

-50

0

50

100

150

200

250

300

0 102030405060

Stickiness H2SD

Nb of sticky neps / km

Stk40

Stk45

Stk55

Figure C-14: Number of sticky neps, detailed analysis.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 198

Detailed analysis : Ring spun yarns

0

100

200

300

400

500

600

700

0 204060

Stickiness H2SD

Number of fiber neps

/ km

F40

F45

F55

Figure C-15: Number of fiber neps, detailed analysis.

Humidity effect

8

9

10

11

12

13

14

15

16

0 102030405060

H2SD Mean

Yarn strength (cN/tex)

RS 40%

RS 45%

RS 55%

HR : *

Cot : ***

Int : NS

Figure C-16: Effect of RH% and stickiness on yarn strength.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 199

6

7

8

9

10

11

0 102030405060

H2SD

Scf on fleeces (Trashcam)

scf40

scf45

scf55

Figure C-17: Number of seed coat fragments in the card fleeces as counted by Cirad’s

Trashcam device.

Detailed analysis : Ring spun yarns

0

50

100

150

200

250

300

350

400

0204060

Stickiness H2SD

Nb of SCF / km

SCF40

SCF45

SCF55

Figure C-18: Detailed analysis on RS yarns: seed coat fragments content.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 200

Humidity effect

0

10

20

30

40

50

60

0 102030405060

H2SD Mean

Thin places (nb/km)

OE 40%

OE 45%

OE 55%

HR : **

Cot : ***

Int : **

Figure C-19: Effect of stickiness and RH% on the number of thin places.

Humidity effect

0

50

100

150

200

250

0 102030405060

H2SD Mean

Thick places (nb/km)

OE 40%

OE 45%

OE 55%

HR : NS

Cot : ***

Int : **

Figure C-20: Number of thick places for different RH% and stickiness values.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 201

Humidity effect

0

50

100

150

200

250

0 102030405060

H2SD Mean

Neps 280 % (nb/km)

OE 40%

OE 45%

OE 55%

HR : **

Cot : ***

Int : ***

Figure C-21: Number of neps 280% at different RH and stickiness values.

Detailed analysis : OE yarns

-20

0

20

40

60

80

100

120

0 102030405060

Stickiness H2SD

Number of sticky neps / km

Stk40

Stk45

Stk55

Figure C-22: Number of sticky neps, detailed analysis.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 202

Detailed analysis : OE yarns

0

10

20

30

40

50

60

0 102030405060

Stickiness H2SD

Number of fiber neps /

km

F40

F45

F55

Figure C-23: Number of fiber neps, detailed analysis.

Detailed analysis : OE yarns

0

10

20

30

40

50

60

70

80

0 102030405060

Stickiness H2SD

Number of SCF / km

SCF40

SCF45

SCF55

Figure C-24: Detailed analysis of OE yarns: seed coat fragments content.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 203

Humidity effect

8.0

8.5

9.0

9.5

10.0

10.5

11.0

11.5

0 102030405060

H2SD Mean

Yarn strength (cN/tex)

OE 40%

OE 45%

OE 55%

HR : NS

Cot : ***

Int : NS

Figure C-25: Yarn strength at different RH and stickiness values.

0%

20%

40%

60%

80%

100%

1234567

F40

Stk40

Div.

Long F

SCF40

0%

20%

40%

60%

80%

100%

1234567

F45

Stk45

Div.

Long F

SCF45

0%

20%

40%

60%

80%

100%

1234567

F55

Stk55

Div.

Long F

SCF55

40 %RH

45 %RH

55 %RH

Detailed analysis

on RS yarns :

results for cotton

ordered by

increasing

stickiness

Figure C-26: Results for RS yarn neps: detailed analysis at different RH%.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 204

40 %RH

45 %RH

55 %RH

Detailed analysis

on OE yarns :

results for cotton

ordered by

increasing

stickiness

0%

20%

40%

60%

80%

100%

1234567

F40

Stk40

Div.

Long F

SCF40

0%

20%

40%

60%

80%

100%

1234567

F45

Stk45

Div.

Long F

SCF45

0%

20%

40%

60%

80%

100%

1234567

F55

Stk55

Div.

Long F

SCF55

Figure C-27: Results for OE yarn neps: detailed analysis at different RH%.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 205

C.6. General conclusion for component B

Component B was designed to evaluate the impact of stickiness on spinning productivity and

quality parameters. The hope was to highlight a stickiness limit below which only manageable

problems would occur during spinning while above it spinners would encounter real problems

that could lead to financial losses. The intention was to use this ‘spinning limit’ as an

evaluation threshold to fix rules in the commercial trading of cotton. Here the results from

component A: the cotton producers being able to fix his own litigation risk as deduced from

the within-bale and within lot variability, it would have been possible to fix the classification

threshold to be respected in the classing offices.

From component A, we learned that it is difficult to derive a statistical law to match the data

observed for all cotton produced in Sudan.

An industrial spinning test confirmed that stickiness induces disruption during spinning and

leads to both productivity and quality losses. In general, this was already well known.

However, we did expect to encounter a flat zone, even if a low degree of stickiness is present

in the fibers, no significant disruption would occur. This is illustrated in Figure C-1. Then,

above a given stickiness limit, which could serve as evaluation threshold, increasing problems

would appear as stickiness increased.

Degree of stickiness (arbitrary scale)

Degree of disruption during spinning

Disruption-free zone Disruption zone

Stickiness limit

Figure C-1: Expected relation between stickiness and disruptions.

From a practical standpoint, it was first necessary to find the best estimator of stickiness. This

was done by taking account of the principle, the precision, the cost and the time consumption

of the measuring method available in this project. Three methods, SCT, HPLC and H2SD

were compared for their ability to predict problems during spinning both in terms of

productivity and yarn quality.

The H2SD measuring device was retained because its results correlate more closely with all

quality and productivity parameters. However, it should be noted that some sugar contents as

measured by HPLC also correlated well with some parameters since they are directly related

to the sugars that cause specific problems during spinning. SCT was not chosen, even if some

relations are shown in this report, since a substantial operator effect was possible on the

reading as seen in ‘Component a’ of this project.

After classification of the sticky points into size classes corresponding to “small”, “medium”

and “large” on H2SD, these experiments did not show any significant trend with the criteria

CFC / ICAC / 11 Project Technical Report on Research Activities Page 206

recorded. This does not mean that this variable has no effect on the spinning process. Further

development work is ongoing to improve the H2SD’s image analysis system so that the

measured size will be closer to that actuelly in the cottons. A more accurate measure of sticky

point size might mean that all the conclusion of this research work would have to be revised.

Indeed, it is probable that a change in sticky point size distributions may appear, and that this

change may affect the existing relations with the spinning process. In this case, it may be

possible that the different sticky point size classes will explain specific productivity or quality

problems in the spinning mill.

The conclusions drawn in this document are highly dependent on the testing conditions of

industrial scale experiments. Thus, the type of machines, their brand (assuming specific

know-how by each textile machinery manufacturer), their settings, the ambient conditions, the

type of work (extensive or intensive labor), the automation level, … can all play important

roles in the way stickiness affects their operation, and therefore in the relations that have been

described.

NB: Any deductions made from the graphs given in this report, are only representative

of our test conditions on specific samples.

From the industrial scale experiment and its specific, restricted operating conditions, we

learned that, as expected, the flat disruption free zone may exist for some quality and

productivity parameters. However, its range may vary in width on the stickiness scale as

measured by H2SD. This means that some productivity and quality parameters may be

affected at low stickiness levels, while other parameters will not be as sensitive to a change in

stickiness.

A specific stickiness level was found at the card where the fibers are cleaned almost

individually. Here, the efects of stickiness were most marked and rendered impossible the

carding of highly contaminated cottons.

This research cannot result in setting a critical threshold for worldwide spinning since the

machine used are so different that some countries are specialized in processing heavily

contaminated cottons, while other do not accept even traces of stickiness among the processed

fibers.

Thus, if a classification procedure is implemented, classification threshold(s) will have to be

set for every customer at a level that depends on his ability to process fibers of a given

stickiness. This would be described in some kind of agreement between two parties. The

organization of such a classification will lead to changes in the way bales are grouped

according to homogeneous stickiness level.

Complementary experiments based on changes in relative humidities (RH) indicated possible

solutions to combat stickiness. These experiments showed that productivity parameters

improved by lowering the relative humidity level and some quality parameters were also

improved or stabilized compared to the normal conditions met in the spinning mills. A clear

effect of RH and stickiness on the micro-spinning process was observed as expected. An

increasing first effect is observed on some productivity parameters for both ring and open-end

micro-spinning when ambient conditions are becoming more humid in the spinning

laboratory. It also exists an increasing effect of stickiness on yarn quality parameters which

goes in the direction of worse quality for almost well-known parameters.

Since it is difficult to choose a range of cotton that differ only by their stickiness level, fiber

quality parameters may interact with the conclusions drawn in this experiment. However,

fiber quality was fairly homogeneous and most of the effects observed in this study can

therefore be considered as mainly dependent on stickiness and the ambient conditions.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 207

Yarn production sometimes required human interventions which had consequences on yarn

quality. This is why we observed some saturation effects in the relationships between

stickiness characteristics and RH conditions.

Nep numbers increased with stickiness and relative humidity as shown by the evenness tester

that separated the different categories of neps: this increase was mainly induced by the

creation of sticky and fiber neps in the yarn.

Mixing a sticky cotton with a non-sticky cotton is an approriate method to decrease the

stickiness level of the mix. A simple formula was derived from the data. However, this

formula is limited since it is no longer predictive when stickiness becomes high. Two

questions remain unsolved:

- large sticky points can be split into different smaller parts during the mixing operations:

do these smaller points have the same behavior as ‘natural’ small points in terms of

consequences on the spinning process ?

- is this formula valid for more than 2 constituants in the mix ?

This experiment was based on relatively small amounts of fibers which, after the mixing

operation, showed comparable sticky points distributions (dispersion index 1.7) to that

observed in industry (dispersion index 1.9).

It is essential to take this information into account when preparing cottons with a range of

stickiness levels to check and/or calibrate the measuring devices. The mixing operation is

increasingly difficult when cottons with low stickiness levels are mixed with a non-sticky

cotton.

To sum up, it is now possible to relate the results from the two first components of this

project. Methodologies were developed to evaluate the within-bale variability of stickiness,

then evalulate, if conditions remain stable, the number of samples taken per bale and the

number of readings required on the measuring devices.

Next, statistical methodology was described to establish thresholds to categorize bales in

different lots according to their stickiness level. In this report, the methodology was applied to

2 category classification for the separation of sticky cottons from non-sticky cottons. The

method can also be applied to form more than 2 stickiness classes.

From the spinning experiment, we learned that no typical, single threshold can be set since

each mill in the world has its own typical machinery and/or knowledge and/or economical

conditions that enable some to process heavily contaminated fibers while others cannot.

In conclusion, classification thresholds can only be defined between producers and users in

accordance with negociated agreements where the most important classification procedure

steps can be discussed depending on the price of the material, the classification, etc … with

respect to standards (meaning: documented methods). This approach complies with the fact

that all standards mention that if test conditions differ from the recommended method, this

must be mentioned in agreements between the parties.

CFC / ICAC / 11 Project Technical Report on Research Activities Page 208