Sync-Rite Plus

™

System

Motors | Automation | Energy | Transmission & Distribution | Coatings

www.electricmachinery.com

Sync-Rite Plus

™

System2

Sync-Rite Plus

™

System

The WEG Electric Machinery Sync-Rite Plus

™

System integrates synchronization controls and rotor

telemetry to provide the information you need to keep your motor up and running.

Less Downtime

Information is the key to reducing downtime. When a motor

won’t synchronize or has a component failure, it is often

difficult to know where to start in addressing the issue. The

typical solution is trial and error until the problem is resolved.

The Sync-Rite Plus

™

System eliminates this slow and costly

process by providing you with the telemetry data required to

immediately identify the issue. With this information,

problems can be solved quickly and motors put back into

service with minimal downtime.

Wireless and Data Logging

J

Data logging capability insures that valuable telemetry

data is always saved.

J

Wireless capability allows access to data without shutting

down the machine.

J

No slip rings, external antennas or wireless receivers

needed in close proximity to rotating transmitter.

Integration

Unlike other telemetry options, the Sync-Rite Plus

™

System

does not require the installation of a separate telemetry

system. By integrating the telemetry system into the

synchronization controller you get the following benefits:

J

High reliability and easy installation due to less components

and less complexity.

J

Ability to correlate the controller’s actions with actual

measurements.

J

Cost savings from only purchasing a single system.

Availability

J

Components of the Sync-Rite Plus

™

System are standard

products for WEG Electric Machinery and are stocked

domestically within the USA.

J

Field tested for multiple industries.

J

System solutions available including NEMA 4X enclosures for

hazardous areas.

Features and Benefits

Sync-Rite Plus

™

Hardwire Data Retrieval

www.electricmachinery.com

3Sync-Rite Plus

™

System

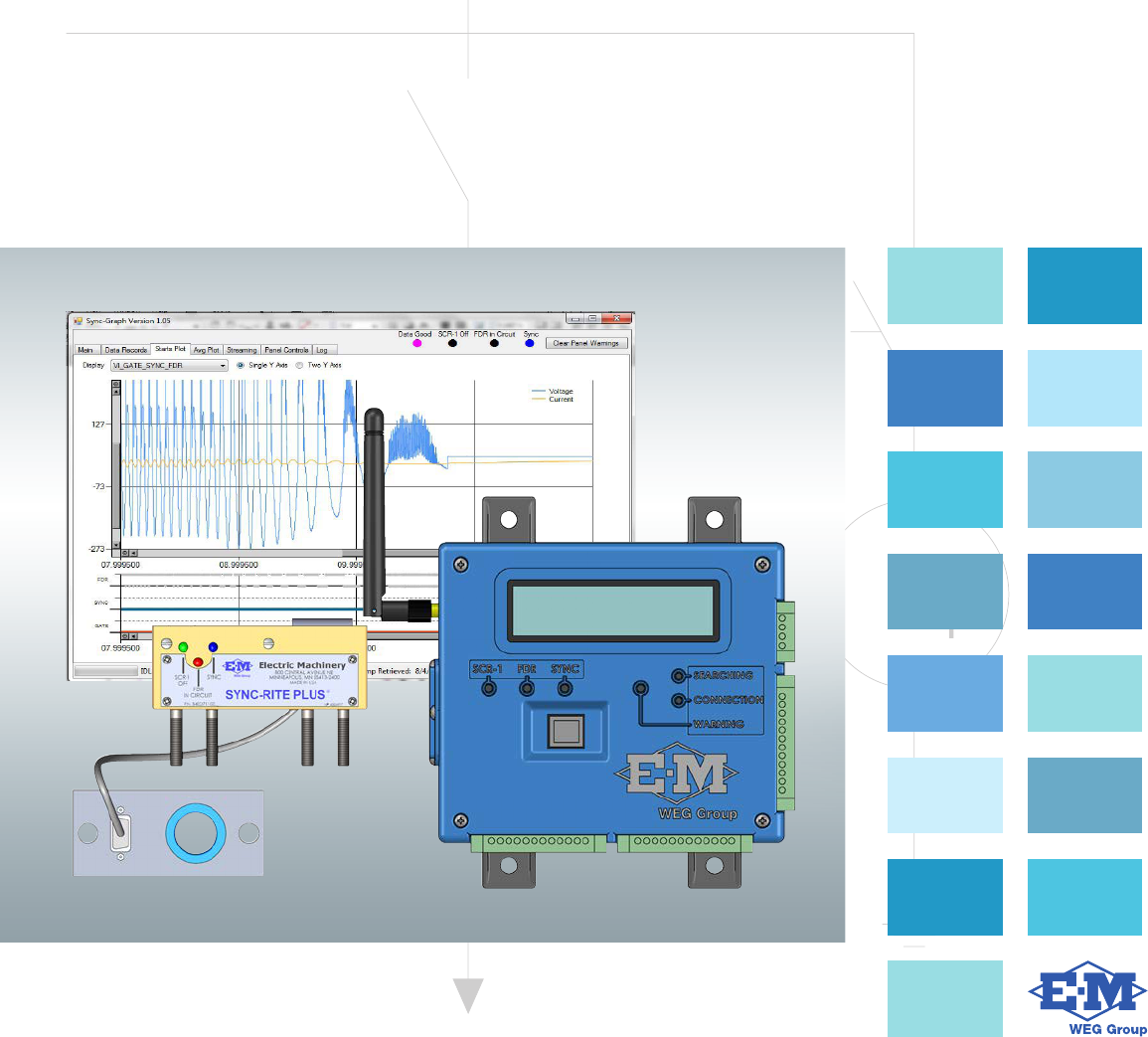

Typical Synchronization Waveforms

Sync-Rite Plus

™

System - Standard Components

Industry leading synchronous motor starting control, now with the added benefits of data logging and

wireless streaming technology.

Sync-Rite Plus

™

Sync-Rite Plus™ Benefits

J

Reliably synchronizes any brushless synchronous

motor.

J

Interchangeable with all legacy Sync-Rite

™

models.

J

Monitors and records the following:

J

Field Voltage

J

Field Current

(with Sync-Rite Plus™ Current Sensor)

J

FDR status (in or out of circuit)

J

Firing of SCR-1

J

Customizable control settings allow controller to be

optimized for various motors and loads.

J

Slip sync speeds from 90% to 99.5%

J

Zero slip sync times from 2 to 5.5 seconds

J

Wireless transceiver for streaming data and

downloading data records without shutting the

machine down.

J

USB port allows data to be gathered from the

machine during outages when the machine is

not running.

J

Starting Records provide an invaluable tool for solving

synchronization issues should they occur.

J

Average Records track changes in the operating

conditions of the machine to identify issues early,

and allows users to take corrective actions before

the issues become serious.

J

Original Sync-Rite

™

Control’s green and red indicators

and a new blue indicator that gives positive

confirmation that the motor has been synchronized.

Sync-Rite Plus

™

Filter

Sync-Rite Plus

™

www.electricmachinery.com

Sync-Rite Plus

™

System4

Sync-Rite Plus

™

Current Sensor

Sync-Rite Plus™ Current Sensor Benefits

The ability to measure and record a synchronous

motor’s field current greatly increases the diagnostic

capabilities of the Sync-Rite Plus

™

System.

Protect Field Windings

Calculation of rotor winding temperature from the

field current and resistance. With this temperature

calculation, it’s possible to detect problems such as

clogged filters or dirty windings. This prevents

serious failures such as failed field windings, and

helps with planning outages for maintenance.

Detect Failed SCRs and Controller

Recording field current during starting makes it easy

to detect failed components.

Identify Loading Issues during Starts

Recording field current during starting also allows

loading issues during starting to be quickly identified

and corrected. This leads to fewer start attempts and

reduced downtime.

The Sync-Rite Plus

™

Current Sensor works with the Sync-Rite Plus

™

to measure and record a

synchronous motor’s field current.

Sync-Rite Plus

™

Current Sensor

Example where a Sync-Rite Plus

™

& Current Sensor were used to monitor a competitor’s controller. The current wave-

form above clearly shows the point at which the controller incorrectly stopped gating the SCR, causing major issues.

Sync-Rite Plus

™

System - Standard Components

Installed Sync-Rite Plus

™

Current Sensor

www.electricmachinery.com

5Sync-Rite Plus

™

System

Sync-Rite Plus

™

Display Panel

Sync-Rite Plus™ Display Panel Benefits

Monitoring Capabilities

J

Convenient and continuous display of field current, voltage,

and temperature

J

Displays easy to understand operating mode messages

along with warning messages

J

Real-time indicators that replicate the LEDs on the

Sync-Rite Plus

™

J

Customizable warning indicator, which can be configured by

the user

J

Proprietary algorithm for detecting open diodes, shorted

diodes, or exciter phase-to-phase shorts

Flexible Data Acquisition Interface

The Panel provides flexible output options for interfacing with

user equipment and data acquisition systems.

J

Three double throw relays that can be configured to

energize based on warnings, synchronization, or wireless

connection state

J

Digital outputs (5V logic) that correspond to relays

J

Three 0 to 5V or 1 to 5V (user selectable range) output

voltages corresponding to the motor’s field voltage, field

current, and estimated field temperature

J

Three 0 to 20mA or 4 to 20mA (user selectable range) output

currents corresponding to the motor’s field voltage, field

current, and estimated field temperature

The Sync-Rite Plus

™

Display Panel is a convenient device for monitoring and downloading data wirelessly from a

Sync-Rite Plus

™

. Whether used as a stand-alone monitoring device, interfaced to a computer, interfaced to user

equipment, or any combination of these, the Sync-Rite Plus

™

Display Panel provides the functionality you need.

Sync-Rite Plus

™

System - Standard Components

Wireless Repeater Benefits

By adding WEG EM’s Wireless Repeaters, the

Sync-Rite Plus

™

Display Panel can be located in control

room or next to data acquisition equipment. This

reduces noise and saves money on interconnections.

J

Each Wireless Repeater extends the wireless range

typically by 200 feet

J

Multiple Wireless Repeaters can be wirelessly linked

together to further extend the wireless range

J

USB port and free, easy to use software makes setting

up the wireless connection easy and hassle free

Wireless Repeater and Power Supply

Wireless Repeater

In some applications, locating the panel close to the machine is either impractical

or inconvenient.

Sync-Rite Plus™ Display Panel

www.electricmachinery.com

Sync-Rite Plus

™

System6

The Online Monitoring Package is Ideal for:

J

Users interested in limiting downtime by utilizing

real-time monitoring and wireless downloads

J

Infrequently starting motors where retrieving records via

USB is impractical since motor is rarely taken offline

J

Frequently starting motors where Starting Records

are invaluable for detecting and solving starting

issues quickly

J

Adding rotor telemetry to existing data acquisition or

monitoring systems

J

Generating alarm based on specific rotor conditions

Requirements

J

Sync-Rite Plus

™

Display Panel Powered by WEG EM

Power Supply 10189104

J

Usable input range: 25-264 VAC or 30-375 VDC

J

Typical wireless range between Sync-Rite Plus

™

and

Sync-Rite Plus

™

Display Panel is 50’

Online Monitoring Package

The Online Monitoring Package includes all the components to take full advantage of all the

Sync-Rite Plus

™

System benefits.

Sync-Rite Plus

™

System - Standard Packages

Sync-Rite Plus

™

Display Panel

Located within 50 feet of the Machine

Sync-Rite Plus

™

Current Sensor

Located on the Rectifier Wheel

Sync-Rite Plus

™

Located on the Rectifier Wheel

Sync-Rite Plus

™

Filter

Located on the Rectifier Wheel

www.electricmachinery.com

7Sync-Rite Plus

™

System

Additional Benefits of the Extended Online

Monitoring Package

J

Allows Sync-Rite Plus

™

Display Panel to be located in

locations where personnel can easily view and access data

such as control rooms

J

Especially valuable for mounting the Sync-Rite Plus

™

Display Panel outside of hazardous areas

J

Ability to locate Panel next to data acquisition equipment

produces cleaner signal waveforms and substantially

reduces wiring

Requirements

J

Sync-Rite Plus

™

Display Panel powered by

included wall adapter power supply

J

Repeater powered by WEG EM Power Supply 10189104

J

Usable input range: 25-264 VAC or

30-375 VDC

J

Typical wireless range between Sync-Rite Plus

™

and Repeater is 50’

J

Typical wireless range between Repeater(s) and

Panel is 200’

Sync-Rite Plus

™

System - Standard Packages

Extended Online Monitoring Package

The Extended Online Monitoring Package provides the freedom to mount the Sync-Rite Plus

™

Display

Panel where it is most convenient. One or more Wireless Repeaters are used in this option to extend

the distance between the Sync-Rite Plus

™

and Display Panel. This allows the Display Panel to be

located in a control room, next to data acquisition equipment, or in any other practical location.

Sync-Rite Plus

™

Located on the Rectifier Wheel

Sync-Rite Plus

™

Display Panel

Located in Control Room, etc.

Wireless Repeater and Power Supply

Located within 50 feet of the Machine

Current Sensor

Located on the Rectifier Wheel

Sync-Rite Plus

™

Filter

Located on the Rectifier Wheel

www.electricmachinery.com

Sync-Rite Plus

™

System8

Sync-Rite Plus

™

System - Standard Packages

Data Logging Package Allows:

J

Data downloads of Starting and Average Records that can be

sent to WEG EM for analysis

J

A lower cost solution that still enables WEG EM to use logged

data for assisting with motor problems

J

Customizable control settings and positive visual confirmation of

synchronization

Requirements

J

Direct USB connection to Sync-Rite Plus

™

for data downloads

Data Logging Option

For customers who don’t want to install an entire Sync-Rite Plus

™

System. WEG EM offers the option of only installing the

Sync-Rite Plus

™

and Sync-Rite Plus

™

Current Sensor

Handheld Preventive Maintenance Package is

Ideal for:

J

Periodically checking motor conditions

J

Troubleshooting

J

Users who want the convenience of a mobile

handheld device

J

Users without data acquisition equipment

Requirements

J

Sync-Rite Plus

™

Display Panel Powered by USB

J

Typical wireless range between Sync-Rite Plus

™

and

Sync-Rite Plus

™

Display Panel is 50’

J

Wireless range can be extended by 200’ with

addition of Wireless Repeater

Handheld Preventive Maintenance Package

A convenient handheld device for periodic maintenance checks and for troubleshooting motor

problems. This is the same package WEG EM Service personnel use in the field.

www.electricmachinery.com

9Sync-Rite Plus

™

System

Sync-Graph Software

Sync-Graph Features

J

Sync-Graph makes it easy to visualize Starting and

Average Records via graphs

J

Track changes in load conditions

J

View conditions that may be preventing

synchronization

J

View changes in field voltage and current over time

J

Track changes in the estimated field temperature

J

The streaming and graphing capabilities of Sync-Graph can

eliminate the need for additional data acquisition equipment

J

Monitor a motor’s field voltage, current, and estimated

temperature along with displaying the Sync-Rite Plus

™

control settings

*Sync-Graph requires the purchase of a Sync-Rite Plus

™

Display Panel.

The Sync-Graph program is a powerful software tool that interfaces with the Sync-Rite Plus

™

Display Panel

for monitoring and downloading data from the Sync-Rite Plus

™

.

Sync-Rite Plus

™

System - Standard Software

Sync-Fetch Features

J

Ability to view Sync-Rite Plus

™

history

J

View the Sync-Rite Plus

™

control settings

J

Allows you to send WEG EM Service both Starting

Records and Average Records if you encounter

a problem

J

All records are time stamped to help correlate

information

J

Records include information about field voltage,

current, FDR’s state (in or out of the circuit), and SCR

gate state (being fired or not)

Sync-Fetch Software

Sync-Fetch Main Information Display

Sync-Fetch is designed to allow users to download data to their computer. This data can then be sent to

WEG EM Service for analysis, carried out according to the current rates.

Example Plot of Sync-Graph Starting Record

www.electricmachinery.com

Sync-Rite Plus

™

System10

Sync-Rite Plus

™

System - Part Ordering Information

Item

No.

Part No. Description

Online

Monitoring

Package

Extended

Online

Monitoring

Package

Handheld

Preventive

Maintenance

Package

Data Logging

Option

1 840D711G02 Sync-Rite Plus

™

X X X X

2 10198852 Sync-Rite Plus

™

Filter X X X X

3 10187117 Sync-Rite Plus

™

Current Sensor X X X X

4 10189104G01

Sync-Rite Plus

™

Display Panel

(External Power Supply, AC or DC)

X

5 10189104G02

Sync-Rite Plus

™

Display Panel

(Wall Mounted Power Supply)

X

6 10189104G03

Sync-Rite Plus

™

Display Panel

(USB Powered)

X

7 10189352G01 Wireless Repeater X Optional

8 - Sync-Graph X X X

9 - Sync-Fetch X

10 10189351G01 Power Supply X X

11 10189460G01 Universal Tester Optional Optional Optional Optional

12 10199579

NEMA 4x Enclosure for

Sync-Rite Plus™ Display Panel

Optional Optional

13 10199577

NEMA 4x Enclosure for

Wireless Repeater

Optional Optional

14 - Data AnalysisReport Optional Optional Optional Optional

Contact WEG Electric Machinery for more information.

www.electricmachinery.com

11Sync-Rite Plus

™

System

Sync-Rite Plus

™

G01 G02

Size

4-1/2” x 2 x 1-3/4”

Weight

24 ounces

Mounting

4 HHCS bolts

Voltage

19-75V 45-250V

Connection Type

Winchester- style screw connector USB

Sync-Rite Plus

™

Current Sensor

G01 G02 G03 G04 G05 G06 G07 G08 G09

Size

4” x 1.2” x 1.825”

Weight

10 ounces

Mounting

2 SHCS bolts and 2 spring lock washers

Maximum Sensing Current

200* 250 300* 400 500 600 800 1000 1200

*Standard Sensor

Sync-Rite Plus

™

Display Panel

G01 G02 G03

Size

6.02” x 5.65” x 1.57”

Weight

14 OUNCES 12 OUNCES

Mounting

4 mounting holes for 1/4” bolts

Power Supply

10189104G01

Included Wall

Adapter

USB 2.0

Additional Electrical Connections

3 DPDT Relays (250 VAC 10 AMP)

3 Analog Voltage Outputs (0-5V or 1-5V)

3 Analog Current Outputs (0-20 mA or

4-20 mA)

4 Digital Outputs (0/5V)

None

Sync-Rite Plus

™

System - Technical Specifications

ELECTRIC MACHINERY COMPANY

800 Central Avenue NE - Minneapolis, MN 55413 USA

Phone: +1 (612) 378 8000, Fax: +1 (612) 378 8050

www.electricmachinery.com

www.weg.net

For those countries where there is not a WEG own operation, find our local distributor at www.weg.net.

6200-BRO-021.1/0316| Rev: 02 | Date (m/y): 03/2016

The values shown are subject to change without prior notice.

For more information, please contact service-[email protected] or 24 Hour Customer Support +1 (612) 247 9232

WEG Worldwide Operations

ARGENTINA

WEG EQUIPAMIENTOS

ELECTRICOS

San Francisco - Cordoba

Phone: +54 3564 421 484

info-ar@weg.net

www.weg.net/ar

WEG PINTURAS - Pulverlux

Buenos Aires

Phone: +54 11 4299 8000

AUSTRALIA

WEG AUSTRALIA

Victoria

Phone: +61 3 9765 4600

www.weg.net/au

AUSTRIA

WATT DRIVE - WEG Group

Markt Piesting

Phone: +43 2633 404 0

watt@wattdrive.com

www.wattdrive.com

BELGIUM

WEG BENELUX

Nivelles - Belgium

Phone: +32 67 88 84 20

www.weg.net/be

BRAZIL

WEG EQUIPAMENTOS ELÉTRICOS

Jaraguá do Sul - Santa Catarina

Phone: +55 47 3276-4002

www.weg.net/br

CHILE

WEG CHILE

Santiago

Phone: +56 2 784 8900

www.weg.net/cl

CHINA

WEG NANTONG

Nantong - Jiangsu

Phone: +86 0513 8598 9333

www.weg.net/cn

COLOMBIA

WEG COLOMBIA

Bogotá

Phone: +57 1 416 0166

www.weg.net/co

ECUADOR

WEG ECUADOR

Quito

Phone: 5144 339/342/317

www.weg.net/ec

FRANCE

WEG FRANCE

Saint Quentin Fallavier - Lyon

Phone: +33 4 74 99 11 35

www.weg.net/fr

GERMANY

WEG GERMANY

Kerpen

Phone: +49 2237 9291 0

www.weg.net/de

WEG BALINGEN

Balingen

Phone: +49 7433 9041 0

info@weg-antriebe.de

www.weg-antriebe.de

GHANA

ZEST ELECTRIC GHANA -

WEG Group

Accra

Phone: +233 30 27 664 90

info@zestghana.com.gh

www.zestghana.com.gh

INDIA

WEG ELECTRIC INDIA

Bangalore - Karnataka

Phone: +91 80 4128 2007

www.weg.net/in

WEG INDUSTRIES INDIA

Hosur - Tamil Nadu

Phone: +91 4344 301 577

www.weg.net/in

ITA LY

WEG ITALIA

Cinisello Balsamo - Milano

Phone: +39 02 6129 3535

www.weg.net/it

JAPAN

WEG ELECTRIC MOTORS

JAPAN

Yokohama City - Kanagawa

Phone: +81 45 550 3030

www.weg.net/jp

MALAYSIA

WATT EURO-DRIVE - WEG Group

Shah Alam - Selangor

Phone: 603 78591626

info@wattdrive.com.my

www.wattdrive.com

MEXICO

WEG MEXICO

Huehuetoca

Phone: +52 55 5321 4231

www.weg.net/mx

VOLTRAN - WEG Group

Tizayuca - Hidalgo

Phone: +52 77 5350 9354

www.voltran.com.mx

NETHERLANDS

WEG NETHERLANDS -

Oldenzaal - Overijssel

Phone: +31 541 571 080

www.weg.net/nl

PERU

WEG PERU

Lima

Phone: +51 1 209 7600

www.weg.net/pe

PORTUGAL

WEG EURO

Maia - Porto

Phone: +351 22 9477705

www.weg.net/pt

RUSSIA and CIS

WEG ELECTRIC CIS

Saint Petersburg

Phone: +7 812 363 2172

www.weg.net/ru

SOUTH AFRICA

ZEST ELECTRIC MOTORS

WEG Group

Johannesburg

Phone: +27 11 723 6000

info@zest.co.za

www.zest.co.za

SPAIN

WEG IBERIA

Madrid

Phone: +34 91 655 30 08

www.weg.net/es

SINGAPORE

WATT EURO-DRIVE - WEG Group

Singapore

Phone: +65 6 862 2220

www.wattdrive.com

WEG SINGAPORE

Singapore

Phone: +65 68589081

www.weg.net/sg

SCANDINAVIA

WEG SCANDINAVIA

Kungsbacka - Sweden

Phone: +46 300 73 400

www.weg.net/se

UK

WEG ELECTRIC MOTORS U.K.

Redditch - Worcestershire

Phone: +44 1527 513 800

www.weg.net/uk

UNITED ARAB EMIRATES

WEG MIDDLE EAST

Dubai

Phone: +971 4 813 0800

www.weg.net/ae

USA

WEG ELECTRIC

Duluth - Georgia

Phone: +1 678 249 2000

www.weg.net/us

ELECTRIC MACHINERY -

WEG Group

Minneapolis - Minnesota

Phone: +1 612 378 8000

www.electricmachinery.com

VENEZUELA

WEG INDUSTRIAS VENEZUELA

Valencia - Carabobo

Phone: +58 241 821 0582

www.weg.net/ve