Waste Reduction Model (WARM)

Data Quality Assessment Report

U.S. Environmental Protection Agency

Office of Land and Emergency Management

Office of Resource Conservation & Recovery

December 2023

EPA-530-R-23-016

WARM Data Quality Assessment 1

Acknowledgements

This WARM data quality assessment report was submitted to the U.S. Environmental Protection Agency,

Office of Resource Conservation and Recovery under Contract: EP‐W‐10‐056, Task Order

68HERH22F0274 by ICF Incorporated, L.L.C. This effort conducted by Deanna Lizas and her team at ICF.

Input and guidance were provided by Priscilla Halloran, Office of Land and Emergency Management,

Office of Resource Conservation and Recovery.

WARM Data Quality Assessment 2

Table of Contents

Acknowledgements ....................................................................................................................................... 1

Table of Contents .......................................................................................................................................... 2

Acronyms and Abbreviations ........................................................................................................................ 3

Executive Summary ....................................................................................................................................... 4

1. Introduction .......................................................................................................................................... 8

2. Approach ............................................................................................................................................. 10

3. Assessment of Material Datasets........................................................................................................ 15

3.1 Plastics and Bioplastics 16

3.2 Metals 19

3.3 Glass 24

3.4 Paper 26

3.5 Electronics 29

3.6 Construction Materials 32

3.7 Tires 45

3.8 Food Waste 48

3.9 Yard Trimmings 52

4. Assessment of Specific Management Pathway Datasets ................................................................... 54

4.1 Landfilling 54

4.2 Composting 56

4.3 Combustion 58

4.4 Anaerobic Digestion 61

5. Conclusion ........................................................................................................................................... 62

6. References .......................................................................................................................................... 64

Appendix: Data Quality Assessment Matrix ............................................................................................... 79

WARM Data Quality Assessment 3

Acronyms and Abbreviations

C&D Construction and demolition

DQ Data quality

DQA Data Quality Assessment

DQG Data Quality Goal

DQI Data Quality Indicator

DQS Data Quality System

EPA U.S. Environmental Protection Agency

GHG Greenhouse gas

HDPE High-density polyethylene

LCA Life Cycle Assessment

LCI Life Cycle Inventory

LDPE Low-density polyethylene

LLDPE Linear low-density polyethylene

MSW Municipal solid waste

ORD EPA Office of Research and Development

PET Polyethylene terephthalate

PP Polypropylene

PVC Polyvinyl chloride

WARM Waste Reduction Model

WARM Data Quality Assessment 4

Executive Summary

This report describes the findings from the detailed assessment of the quality of the data used to

develop the greenhouse gas (GHG) emission and energy factors in the U.S. Environmental Protection

Agency’s (EPA) Waste Reduction Model (WARM).

1

The purpose of this effort is to support EPA in

understanding and improving the data quality in WARM, and to provide additional transparency and

insight on the underlying data for WARM users. The report also offers recommendations for prioritizing

future updates.

This data quality assessment (DQA) involved a comprehensive review of the datasets used in the WARM

modeling for each material type and materials management pathway. The data quality for each data

source used to develop the WARM GHG emission and energy factors was evaluated for each of the flow

and process indicators described in EPA’s “Guidance on Data Quality Assessment for Life Cycle Inventory

Data” (Edelen and Ingwersen 2016). Flow indicators consider the reliability of the measurements, and

the correlation of the age of data, geographical coverage, and technological representativeness with the

study’s data quality goals. Process indicators consider the data review process used and the

completeness of the dataset.

The calculation of averages for each indicator grouping and for each material type and pathway

facilitated the assessment of the overall data quality for a material category or management pathway—

particularly across the large number of datasets and over 60 material types. Average scores were

translated into data quality levels, ranging from low to high. To give additional weight to the key data

sources driving emission and energy factor estimates for a material category, weighted average scores

also were calculated along with average scores.

1

Available at https://www.epa.gov/warm.

WARM Data Quality Assessment 5

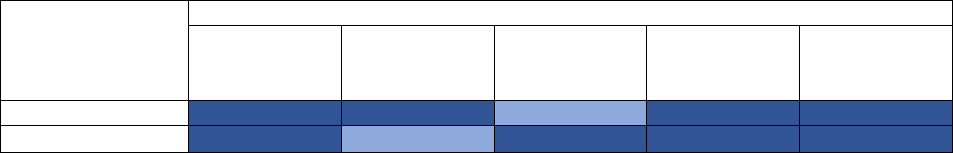

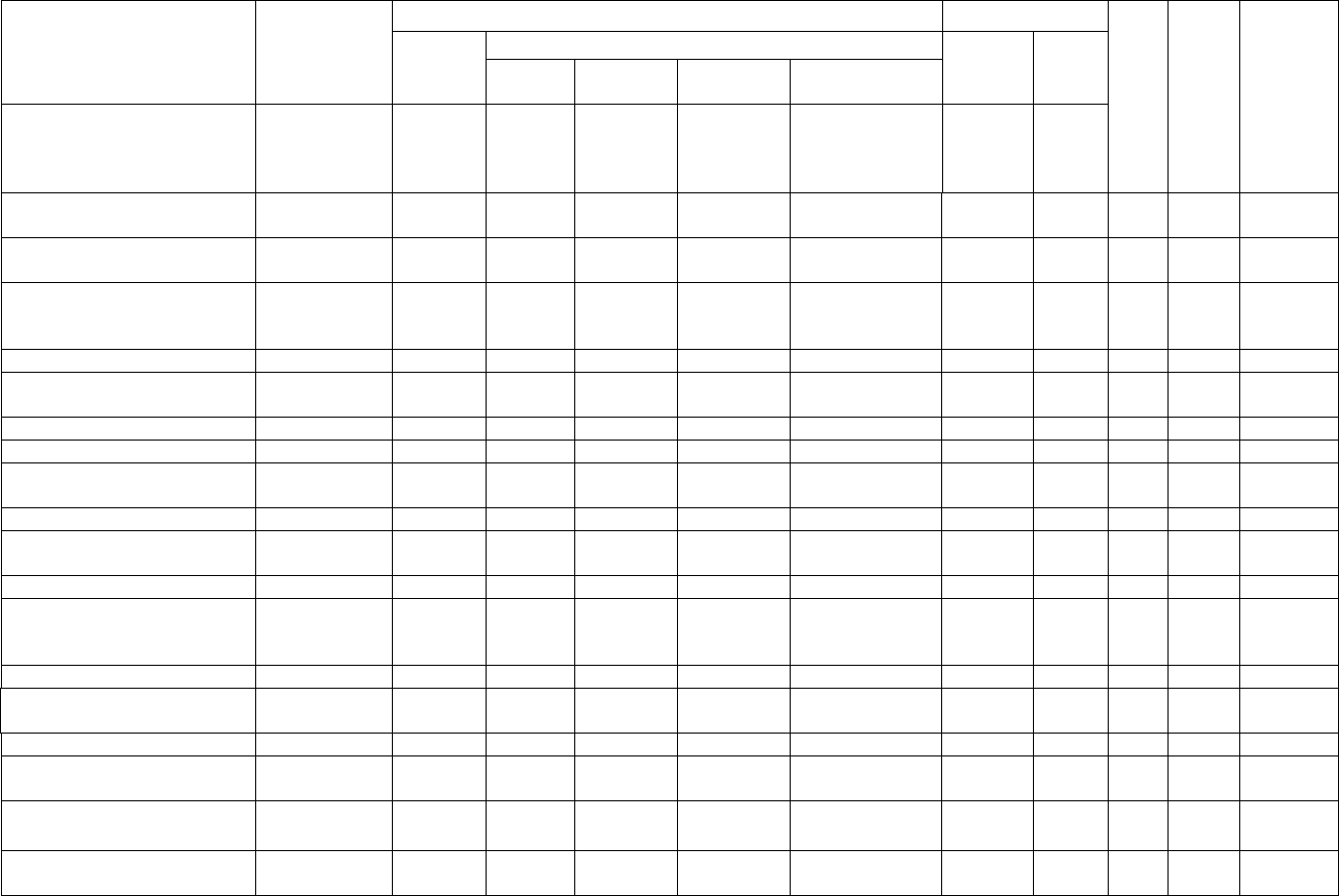

Table 1 summarizes findings on data quality for the data quality indicator groupings by material category

and management pathway. The shading offers a big picture heat-map-like view of the data quality

findings with darker shading indicating higher data quality and lighter shading indicating lower data

quality. The report provides detail on these data quality results, and the Appendix: Data Quality

Assessment Matrix. This Appendix presents the scoring details in a matrix form by material,

management pathway, and dataset.

WARM Data Quality Assessment 6

Table 1: Summary of Data Quality Results by Material Type or Management Pathway

Material or Pathway

DQ Values by Indicator Grouping

Flow

Reliability

a

Flow

Represent-

ativeness

b

Process Review

and

Completeness

c

Average

d

Weighted

Average

e

Material Category

Plastics

Medium-high

Medium-high

Medium

Medium-high

Medium-high

Bioplastics

Medium-high

Medium

Medium-high

Medium-high

Medium-high

Metals

Medium

Medium

Medium

Medium

Medium

Glass

Medium

Medium

Medium

Medium

Medium-low

Paper

Medium-low

Medium

Medium-low

Medium-low

Medium

Electronics

Medium-high

Medium-high

Medium-high

Medium-high

Medium-high

Construction Materials

Medium-high

Medium-high

Medium-high

Medium-high

Medium-high

Asphalt Concrete

Medium-high

Medium

Medium-high

Medium-high

Medium

Asphalt Shingles

Medium-low

Medium

Medium

Medium

Medium

Carpet

Medium

Medium-low

Medium-low

Medium-low

Medium

Clay Bricks

Medium-high

Medium-high

High

Medium-high

High

Concrete

High

Medium-high

Medium

Medium-high

Medium-high

Dimensional Lumber

Medium-high

Medium-high

High

Medium-high

Medium-high

Drywall

Medium-high

Medium-high

Medium-high

Medium-high

Medium-high

Fiberglass Insulation

Medium

Medium

Medium

Medium

Medium

Fly Ash

Medium-high

Medium-high

Medium

Medium-high

Medium-high

Medium-density

Fiberboard

Medium-high

Medium-high

High

Medium-high

Medium-high

Structural Steel

Medium-high

Medium-high

Medium-high

Medium-high

Medium-high

Vinyl Flooring

Medium-high

Medium

Medium-high

Medium

Medium

Wood Flooring

Medium-high

Medium

Medium-high

Medium-high

Medium-high

Tires

Medium

Medium

Medium

Medium

Medium

Food Waste (non-meat)

Medium-high

Medium

Medium-high

Medium

Medium

Food Waste (meat)

Medium-high

Medium-high

Medium-high

Medium-high

Medium-high

Yard Trimmings

Medium-high

Medium-high

Medium-high

Medium-high

Medium-high

Management Pathway

f

Landfilling

Medium-high

Medium-high

Medium-high

Medium-high

Medium-high

Composting

Medium-high

Medium

High

Medium-high

Medium-high

Combustion

Medium

Medium-low

Medium

Medium

Medium

Anaerobic Digestion

Medium-high

Medium

Medium-high

Medium-high

Medium

a

Refers to data generation method and verification.

b

Includes temporal correlation (data year), geographical correlation (region of data), technological correlation (technology type,

scale), and data collection methods (representativeness, sample size).

c

Includes process review (third party or internal reviewers) and process completeness (percent of flows covered).

d

Average of all indicators.

e

Developed to give additional weight to the key data sources informing the emission factor estimates.

f

Separate data quality assessments for source reduction and recycling were not conducted as their data sources were already

captured under the material-specific data assessments.

WARM Data Quality Assessment 7

Key findings from this assessment include the following:

• Overall results: The average and weighted average

2

data quality levels for the WARM data

sources were assessed to be medium to medium-high for most material categories and

management pathways.

• Results by material category: Based on the weighted average of data quality results across the

indicators, medium-high data quality was found for plastics, bioplastics, electronics,

construction materials, food waste (meat), and yard trimmings; medium quality was found for

metals, paper, food waste (non-meat), and tires; and medium-low for glass. Within the

construction materials category, data quality results ranged from medium for asphalt concrete,

asphalt shingles, carpet, fiberglass insulation, and vinyl flooring to high data quality for bricks.

• Results by management pathway: Based on the weighted average of data quality results across

the indicators, medium-high data quality was found for landfilling and composting, and medium

for combustion and anaerobic digestion.

• Results by indicator: Process review and completeness generally had the highest data quality.

While several data sources had lower data quality for the temporal correlation indicator (a sub-

category of flow representativeness) due to age of data, this did not lead to low overall data

quality due to the other data quality considerations.

This assessment informed the following recommendations:

• Identify more recent data sources for select materials.

• Identify published data sources to update certain data inputs.

• Prioritize updates to the modeling of glass, paper, metals, food waste (non-meat), carpet,

asphalt shingles, fiberglass insulation, vinyl flooring, tires, and combustion.

• Improve the archiving and accessibility of the underlying data sources.

• Communicate the DQA findings alongside the WARM documentation.

2

Considers additional weighting for key data sources used in a particular category.

WARM Data Quality Assessment 8

1. Introduction

The U.S. Environmental Protection Agency’s (EPA) Waste Reduction Model (WARM) is a tool for

estimating the life-cycle greenhouse gas (GHG) emission, energy, and economic impacts of various

materials commonly found in municipal solid waste (MSW) under baseline and alternative waste

management scenarios. Currently, the model includes over 60 different materials and the materials

management pathways of source reduction, recycling, composting, combustion, landfilling, and

anaerobic digestion. EPA first developed WARM as a way to quantify the connection between waste

management practices and climate change, and to determine the potential for source reduction and

recycling of MSW to reduce GHG emissions. The first documentation report applying the WARM GHG

and energy factors, entitled Greenhouse Gas Emissions from Management of Selected Materials in

Municipal Solid Waste, was published in 1998. At the time, WARM included 17 material types commonly

found in MSW. Since then, EPA has expanded the model to include dozens of additional material types,

incorporated more sophisticated modeling of the management practice pathways, added the anaerobic

digestion pathway, quantified economic impacts, and made many other updates and improvements. In

addition, EPA organized the WARM documentation into chapters by material and pathway to provide

WARM users with detailed information about the specific materials analyzed in WARM and the

calculations behind the specific material emission, energy, and economic factors in the model. The

currently available online Excel version of the tool is version 15 available at epa.gov/warm.

WARM relies on numerous data sets for the development of material-specific GHG emission, energy,

and economic factors.

3

This report summarizes the detailed review of the data sources behind WARM

and an analysis of the quality of the data used to develop the emission and energy factors in the model.

The purpose of this effort is (a) to support EPA in understanding and improving upon the data quality in

WARM and prioritizing future updates, and (b) to provide additional transparency and insight on the

underlying data for WARM users. This effort is intended to shed light on areas for data quality

improvement, particularly across the numerous and diverse data sets used to develop WARM’s factors.

Importance of Data Quality to EPA

Data quality is critically important to EPA’s programs. Understanding and maintaining the quality of data

is a crucial aspect of the EPA’s scientific process, as outlined in the EPA Order CIO 2105.0 policy on

mandatory agency-wide quality systems (EPA 2000). EPA recognizes that low quality datasets or values

can in turn affect the integrity of values that rely on that data. Through a comprehensive assessment of

data quality, EPA seeks to advance the understanding of data quality, increase transparency, and

ultimately improve upon the data quality. Federal legislation is driving EPA and other federal agencies to

prioritize data accessibility. The Foundations for Evidence-Based Policymaking Act of 2018 mandates that

agencies such as the EPA improve the accessibility of data and use statistical evidence in the

development of policies and evaluation plans (H.R.4174 – 115

th

Congress 2017-2018). EPA implements

internal guidelines to guarantee the collection of data is done correctly and the quality of the data is

3

The methodology used to develop the WARM emission, energy, and economic factors is detailed in the WARM

Documentation, available at https://www.epa.gov/warm/documentation-waste-reduction-model-

warm#documentation.

WARM Data Quality Assessment 9

maintained. These regulations and guidelines exist to establish the credibility and trust of the

information produced by EPA and other federal agencies.

As part of the agency’s efforts to prioritize and carry-out data quality improvements, EPA has invested in

the development of guidance on data quality assessments and comprehensive evaluations of the quality

of data used in its analyses and programs. EPA’s Office of Research and Development (ORD) developed a

systematic methodology for data quality assessment (DQA) for life cycle inventory (LCI) data. This

approach is detailed in the “Guidance on Data Quality Assessment for Life Cycle Inventory Data” (ORD

Guidance) and discussed in further detail in the following Approach section (Edelen and Ingwersen

2016). Life cycle assessments (LCA), which evaluate environmental impacts across the life stages of a

material, product, or system, rely on many data inputs. LCA practitioners often use different

methodologies, tools, and approaches for documentation, and assessment of data quality can become

subjective. The ORD Guidance helps standardize the data quality review process to improve objectivity

in the scoring process, allowing for reproducibility of data quality scores, and improving understanding

of LCI data quality.

What is a Data Quality Assessment?

A data quality assessment (DQA) is a systematic review of a data source to determine its reliability and

level of quality as it relates to the goal and scope of the study or analysis. Rather than deeming a data

source good or bad, a DQA conducts a multi-pronged review based on several key analysis points. For

this DQA, each data source was reviewed based on several flow and process indicators. Flow indicators

consider the reliability of the measurements, and the correlation of the age of data, geographical

coverage, and technological representativeness with the study’s data quality goals (DQGs). Process

indicators consider the data review process used and the completeness of the dataset. As noted in the

ORD Guidance, the goal of a DQA with the use of a pedigree matrix scoring approach is to “see where

potential data quality issues might exist within large datasets and/or models with multiple processes”

(Edelen and Ingwersen 2016).

In understanding the results from a DQA, it is important to recognize a few key elements:

• Certain data quality results are static, while others are dynamic. Reliability of the data, based on

how the data were developed, is a static, unchanging, data quality element. Temporal

correlation is a dynamic data quality element that will change depending on a user’s timeframe

of study and the strength of a dataset’s correlation will change with the passing of time.

• A DQA may not capture all data sources or all data quality elements. Certain data may be

unavailable or inaccessible. Other data may be unknown to a data developer or may not be

possible to quantify.

• The user dimension is an important piece of how data quality results are interpreted. The data

quality can help inform how data are used by a particular user or for a specific purpose (e.g., for

certain uses or applications, a lower data quality dataset may be sufficient). In addition, while a

data developer is responsible for documenting and clearly communicating data quality

elements, a data user is responsible for assessing the appropriateness of the applications and

uses of the data.

WARM Data Quality Assessment 10

In the case of WARM, users of the tool and the emission and energy factors need to be aware that the

development of the factors includes multiple data sources and assumptions. This report describes the

data sources and assesses the quality of each of the data sets, to the extent feasible. A concerted

attempt was made to include all known data sources used for the emission and energy factor

development. The WARM documentation chapters

4

provide additional detail on the data sources and

discuss the boundaries of the analysis, the methodologies used to develop the factors, and limitations

related to the modeling of the emissions and energy use for the various material categories and

management practices.

The remainder of this report is organized as follows:

• Section 2: Approach

• Section 3: Assessment of Material Datasets

• Section 4: Assessment of Specific Management Pathway Datasets

• Section 5Error! Reference source not found.: Error! Reference source not found.Conclusion

• References

• Appendix: Data Quality Assessment Matrix

2. Approach

The scope of this assessment focused on the data used to develop the greenhouse gas (GHG) emission

and energy factors in EPA’s Waste Reduction Model (WARM). The factors are built with life-cycle

inventory and assessment data from various sources with a focus on prioritizing publicly available, peer-

reviewed reports, literature, and databases. The approach used for the data quality assessment (DQA)

follows that described in the “Guidance on Data Quality Assessment for Life Cycle Inventory Data”

developed by EPA’s Office of Research and Development (ORD Guidance) (Edelen and Ingwersen 2016).

The ORD Guidance specifies data review elements at the flow and process levels. The flow level

indicators cover reliability and representativeness of the data, and the process level indicators cover the

review process and completeness of the dataset.

The ORD Guidance provides data quality indicators (DQIs) to accurately assess the “functionality of data

within the boundaries of a particular study or project goal and scope” for life cycle inventory (LCI) data.

The guidance not only provides detailed information on the relevance and applicability of each

identified DQI, but also provides direction for developing a pedigree matrix data quality system (DQS)

with objective and clear scoring parameters. The DQA process involves scoring of five flow indicators

and two process indicators, as described in Table 2.

4

Available at https://www.epa.gov/warm.

WARM Data Quality Assessment 11

Table 2: Indicators Used for Assessing and Scoring the Quality of Data Sources

Indicator

Description

Flow Indicators

Flow Reliability

Used for reviewing if measurements and calculations in a source are verified and

reliable.

Temporal Correlation

Used for measuring the age difference between the temporal data quality goal

(DQG) and the data generation date in a source.

Geographical Correlation

Used for reviewing the relationship between the geographical DQG and the area

of study in a source.

Technological Correlation

Used for reviewing the relationship between the technological DQG and the

technological approach in a source. There are four categories of technological

representativeness reviewed by this indicator: process design, operating

conditions, material quality, and process scale. More information on these

categories can be found in the Appendix.

Data Collection Methods/

Representativeness

Used for identifying if a significant percentage of the relevant market share of an

industry is covered over an adequate time period by a source.

Process Indicators

Process Review

Used for identifying if a source has been reviewed by adequate third-party

reviewers and if proper documentation of the review accompanies the data in a

source.

Process Completeness

Used for identifying the percentage of flows determined for a process that has

been evaluated and assigned a value in a source.

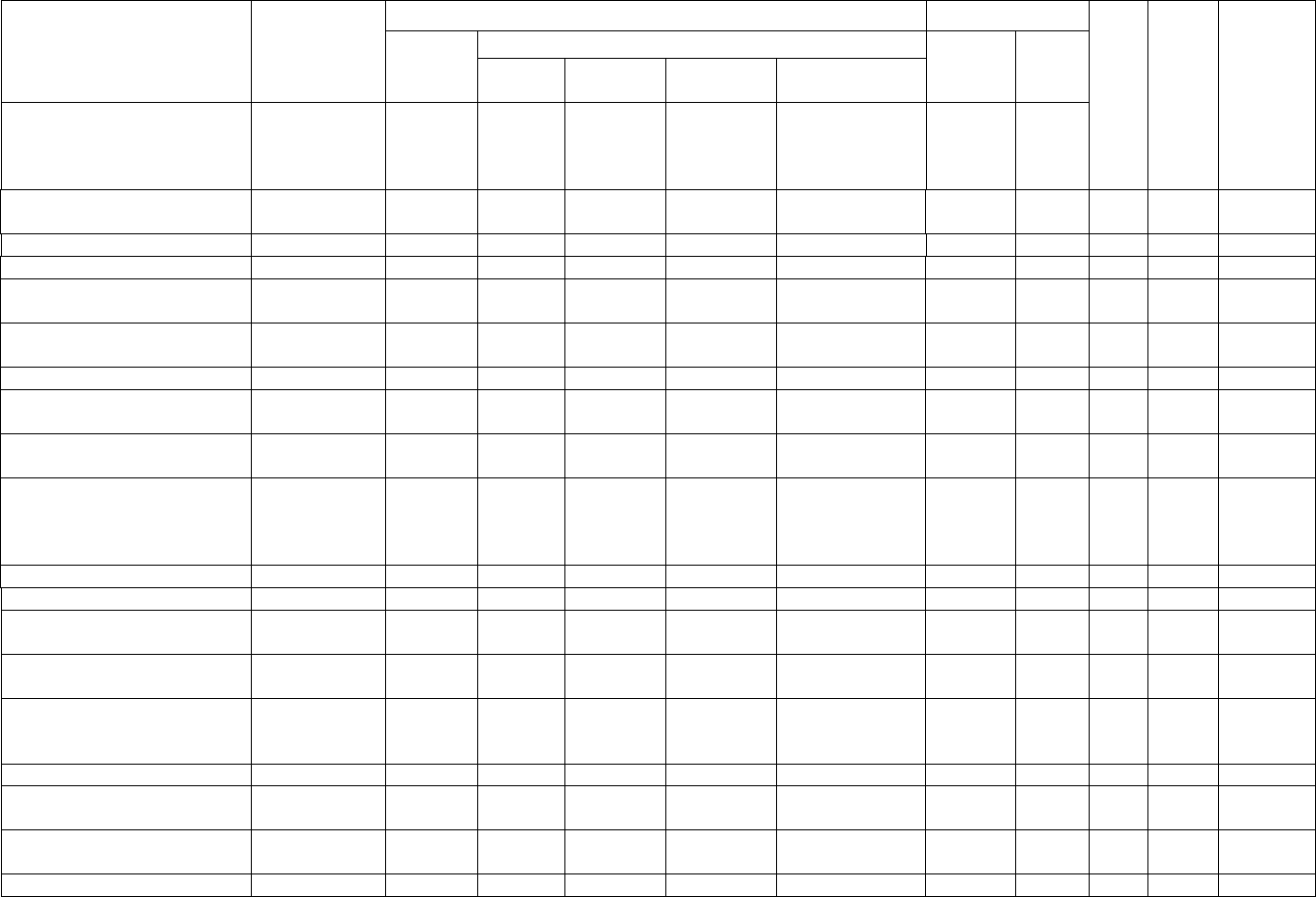

The scoring for each indicator, as described in the ORD Guidance, ranges from 1-5 with the lowest score,

1, representing the highest quality data. A lower cumulative score or average score of all indicators

represents a data source with high quality data and methodology, whereas a higher score indicates

poorer data quality. The Data Quality Pedigree Matrix with the scoring range descriptions for each flow

and process DQI from the ORD Guidance is presented in Table 3.

WARM Data Quality Assessment 12

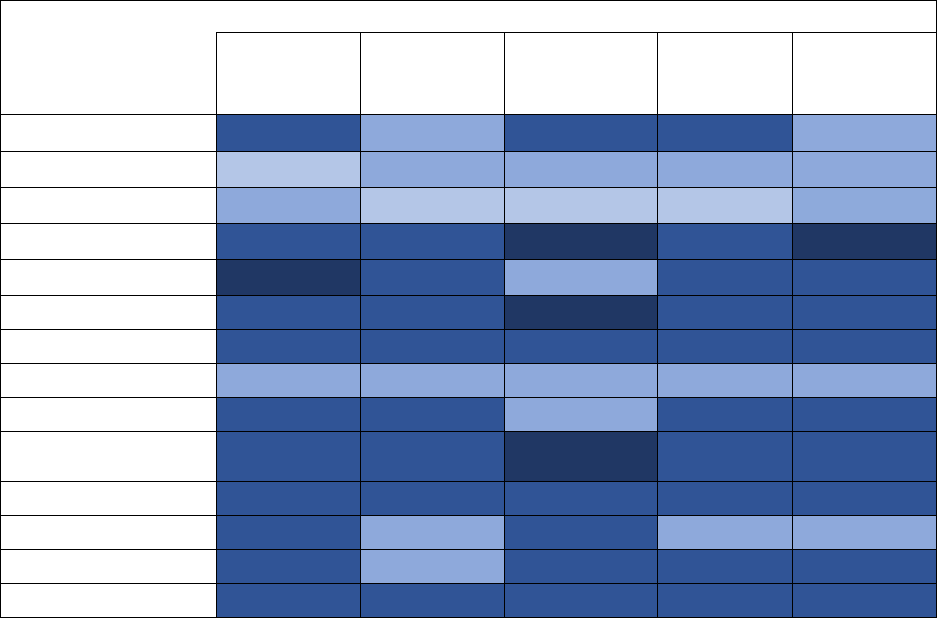

Table 3: Data Quality Pedigree Matrix for Flow and Process Indicators

Highest data quality

Lowest data quality

Indicator

1

2

3

4

5

Flow Indicators

Flow Reliability

Verified data based

on measurements

a

Verified data based

on a calculation or

non-verified data

based on

measurements

Non-verified data

based on a

calculation

Documented

estimate

Undocumented

estimate

Flow Representativeness

Temporal

Correlation

Less than 3 years of

difference

b

3 to 6 years of

difference

Less than 10 years

of difference

Less than 15 years

of difference

Age of data

unknown or more

than 15 years

Geographical

Correlation

c

Data from same

resolution and

same area of study

Within one level of

resolution and a

related area of

study

Within two levels

of resolution and a

related area of

study

Outside of two

levels of resolution

but a related area

of study

From a different or

unknown area of

study

Technological

Correlation

d

All technology

categories are

equivalent

Three of the

technology

categories are

equivalent

Two of the

technology

categories are

equivalent

One of the

technology

categories is

equivalent

None of the

technology

categories are

equivalent

Data Collection

Methods

Representative

data from >80% of

the relevant

market

e

, over an

adequate period of

time

f

Representative

data from 60-79%

of the relevant

market, over an

adequate period or

representative of

data from >80% of

the relevant

market, over a

shorter period of

time

Representative

data from 40-59%

of the relevant

market, over an

adequate period of

time or

representative

data from 60-79%

of the relevant

market, over a

shorter period of

time

Representative

data from <40% of

the relevant

market, over an

adequate period of

time or

representative

data from 50-59%

of the relevant

market, over a

shorter period of

time

Unknown or data

from a small

number of sites

and from shorter

periods

Process Indicators

Process Review

Documented

reviews by a

minimum of two

types

g

of third-

party reviewers

Documented

reviews by a

minimum of two

types of reviewers,

with one being a

third party

Documented

review by a third-

party reviewer

Documented

review by an

internal reviewer

No documented

review

Process Completeness

>80% of

determined flows

have been

evaluated and

given a value

60-79% of

determined flows

have been

evaluated and

given a value

40-59% of

determined flows

have been

evaluated and

given a value

<40% of

determined flows

have been

evaluated and

given a value

Process

completeness not

scored

a

Verification may take place in several ways, e.g., by on-site checking, by recalculation, through mass balances or cross checks with other

sources. For values calculated from a mass balance or another verification method, an independent verification method must be used to

qualify the value as verified.

b

Temporal difference refers to the difference between date of data generation and the date of representativeness as defined by the scope of

the project.

c

Geographical representativeness for this study set is based on EPA data quality goals of national data 1: U.S. data, national in scope; 2: U.S.

data, state or local level in scope; 3: North American data; 4: Global data; 5: Unknown location of data.

d

Technological categories are process design, operating conditions, material quality, and process scale.

e

The relevant market should be documented in the DQG. The default relevant market is measured in production units. If the relevant market

is determined using other units, this should be documented in the DQG. The relevant market established in the metadata should be

consistently applied to all flows within the unit.

f

Adequate time period can be evaluated as a time period long enough to even out normal fluctuations. The default time period is 1 year,

except for emerging technologies (2-6 months) or agricultural projects >3 years.

g

Types are defined as either industry or LCA experts.

WARM Data Quality Assessment 13

Following the ORD Guidance and using the DQIs described above, this assessment involved the following

steps:

➢ Step 1: Review of WARM DQGs: To ensure a systematic review of the various datasets, the process

began with a review of the DQGs for an ideal WARM dataset as they align with the various DQIs.

These WARM DQGs are outlined in Error! Reference source not found. below:

Table 4: WARM Data Quality Goals Aligned to the Indicators

Indicator

WARM Goal

Flow Indicators

Flow Reliability

Documented data are ideally verified by in-person authentication or

repeatable calculation measurements.

Flow Representativeness

Temporal Correlation

Temporal correlation with data collected, measured, or estimated as

recent as possible to the present without compromising in the other data

quality areas.

Geographical Correlation

Data represent U.S. conditions at the national level.

Technological Correlation

Strong technological correlation to the process or technology addressed

for each material or management pathway, with clear information on

inputs. Studies should ideally reflect the current processes employed by

the market.

Data Collection Methods

Representative of the majority of the market over a reasonable period of

time to avoid outlying data, ideally within one year.

Process Indicators

Process Review

Data are reviewed by at least one third-party reviewer, ideally multiple.

Process Completeness

Majority of the determined flows evaluated in the LCI datasets.

➢ Step 2: Creation of a DQA Review Matrix: A comprehensive data quality review matrix in Excel

covering the DQIs within the ORD Guidance was created and used to review each dataset in a

systematic way.

➢ Step 3: Identification of Data Elements and References: Multiple data sources are used to develop

the emission and energy factors for each material type in WARM. For this DQA effort, each material

type and management pathway in WARM, the key unit process data elements and corresponding

data sources and source years were identified. To do so, each source referenced in the WARM

documentation and emission and energy factor calculations spreadsheet used to develop the latest

version of WARM was included in the DQA review matrix.

➢ Step 4: Collection of the Data Sources: The ORD Guidance describes the importance of using and

assessing the original documentation. The original data sources for each data element as referenced

in the WARM documentation were identified and gathered to the extent feasible within archives. As

part of this effort, a comprehensive archive of the underlying data resources by material category

and end-of-life pathway was created. A few sources for specific material types and management

pathways could not be located, particularly documentation of prior conversations with industry

experts. These sources were given the lowest data quality scores.

WARM Data Quality Assessment 14

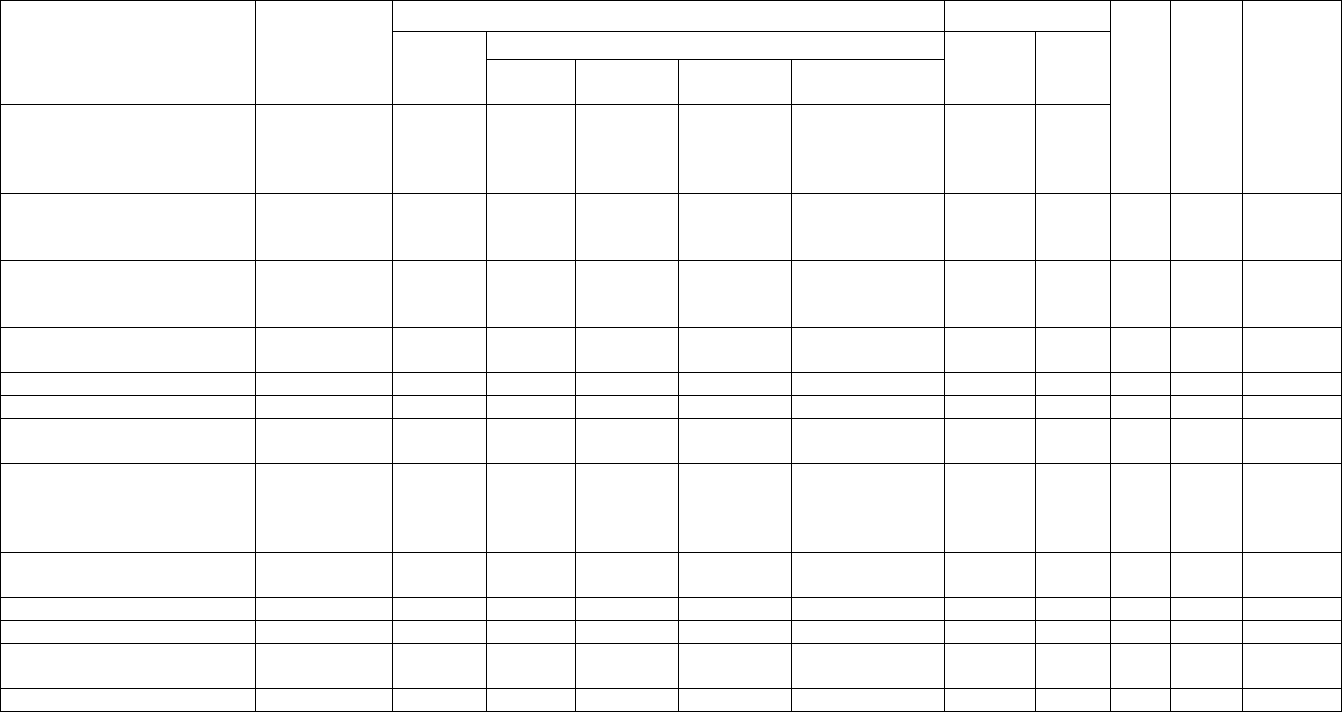

➢ Step 5: Review of Data Sources and Scoring Assessment of Data Quality: The gathered data sources

were reviewed against the different DQIs and the data quality findings were noted. For each data

source, each indicator was scored based on the ORD Guidance criteria in Table 3 and the totals

across the indicators were summed to obtain a total score, ranging from 7 (highest quality) to 35

(lowest quality). The average across the indicators was also taken and ranged from 1 to 5. For an

example of this process, a plastic data source received the scores shown in Table 5 for the five flow

indicators and two process indicators, which sum to the total score of 16 and average to 2.3.

Table 5: Example of DQ Scoring Assessment for a Single Data Source

Flow Indicators

Process Indicators

Total

Score

Average

Score

Flow Reliability

Flow representativeness

Process

Review

Process

Completeness

Temporal

correlation

Geographical

correlation

Technological

correlation

Data collection

methods

Data generation

method &

verification

Data year

Region of

data

Technology

type, scale

Representativeness,

sample size

Third party

or internal

reviewer(s)

% of flows

covered

1

5

1

2

1

5

1

16

2.3

To give additional weight to the key data sources driving emission and energy factor estimates for a

material category, a weighted average score was calculated along with an average score. While the

average score takes the total score for all data sources and divides by the number of sources for

each material type, the weighted average redistributes the weight of each study’s score based on

whether the data source is a driving factor in overall emissions. For example, a source was generally

considered key if it impacts several materials within a category, is a lead source in process emission

estimates, or is comprehensive enough to be used throughout the life cycle of a material’s emission

estimates. In the weighted average score, key sources were given double the weight of other, non-

key sources.

➢ Step 6: Alignment of Scores with Data Quality Levels: Across multiple data sources for a material

category or pathway, the averages for high level indicators of flow reliability, flow

representativeness, and process review and completeness were taken and used to develop average

data quality values across that material category or pathway. The averaged data quality values were

aligned with data quality levels from low to high as shown in Table 6. To present the results in a

more visual way, a shading system was applied to the scores where pale blue was assigned to the

lowest data quality level with an average data quality value of one and dark blue was assigned to the

highest data quality level corresponding with an average data quality value of five. Between those

data quality levels and values the shading scales from light blue for low data quality to dark blue for

high data quality. In the case of the example data source above, the average score of 2.3 aligned

with a data quality level of medium-high.

WARM Data Quality Assessment 15

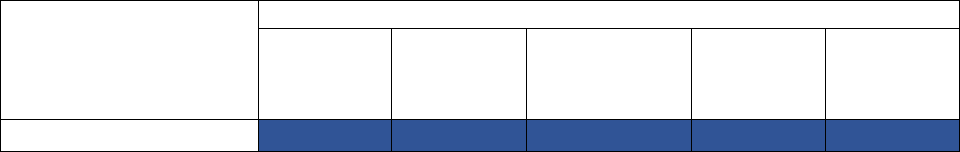

Table 6: Alignment of Average Data Quality Values with Data Quality Levels

Average DQ Value

DQ Levels

1

High

2

Medium-high

3

Medium

4

Medium-low

5

Low

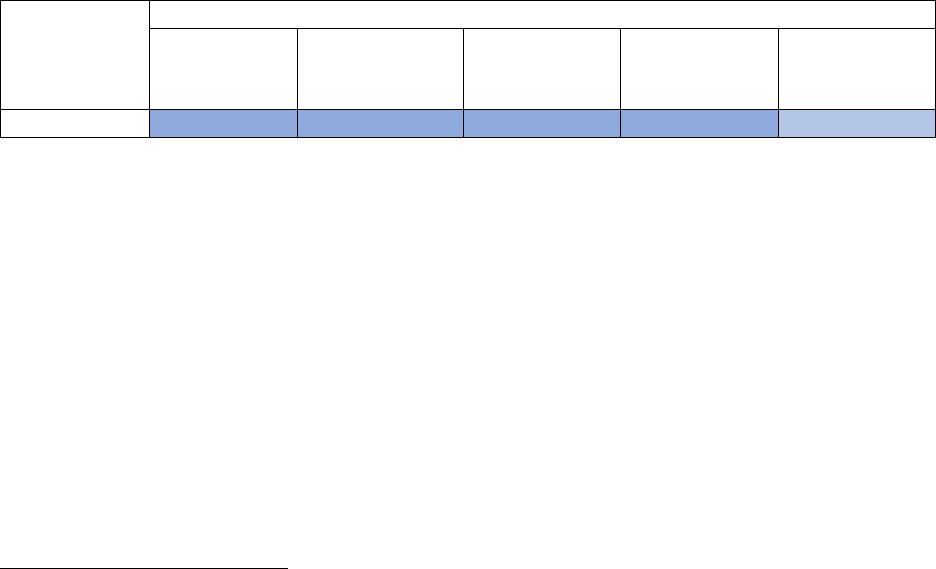

➢ Step 7: Assessment of Results: Based on the scoring assessment, the resulting matrix was organized

into the categories – high, medium-high, medium, medium-low, and low data quality scores. For

each material category and management pathway the following summary table is presented in the

sections that follow.

Management

Pathway

DQ Values by Indicator Grouping

Flow

Reliability

a

Flow

Represent-

ativeness

b

Process

Review and

Completeness

c

Average

d

Weighted

Average

e

a

Refers to data generation method and verification.

b

Includes temporal correlation (data year), geographical correlation (region of data), technological correlation (technology type,

scale), and data collection methods (representativeness, sample size).

c

Includes process review (third party or internal reviewers) and process completeness (percent of flows covered).

d

Average of all indicators.

e

Developed to give additional weight to the key data sources informing the emission factor estimates.

The materials or pathways with datasets receiving the lowest data quality scores and the indicators

contributing to those scores were identified and will require closer examination to inform

prioritization of future WARM updates.

➢ Step 8: Preparation of Findings and Recommendations: This report was developed to summarize

key findings, areas for improvement, and recommendations for addressing WARM’s data quality.

Weighted averages were calculated to provide additional context to the reader and give a deeper

view into how different data sources were used. These weighted averages could also be used in the

future to help prioritize updates to source materials.

3. Assessment of Material Datasets

The following sections present the results from the assessment of the quality of the datasets and data

sources by material category (e.g., metals) and type (e.g., aluminum cans). Summaries of key findings

are presented followed by recommended areas for further research and improvement of the data

quality. In the discussion of data sources, key sources used in the development of the emission and

energy factors are noted as (KEY). They are weighted more heavily for the development of the weighted

averages. Additional details on the scoring results from the assessment of the flow level and process

level indicators for each material data source are presented in the Appendix: Data Quality Assessment

Matrix.

WARM Data Quality Assessment 16

3.1 Plastics and Bioplastics

Summary of Key Findings

Data Sources. WARM includes emission and energy factors for seven plastic resins—high-density

polyethylene (HDPE), low-density polyethylene (LDPE), polyethylene terephthalate (PET), linear low-

density polyethylene (LLDPE), polypropylene (PP), general purpose polystyrene (GPPS), and polyvinyl

chloride (PVC)—a mixed plastics category, and the bioplastic, polylactide (PLA) biopolymer resin. The

development of the factors relied on the use of both key sources and additional sources, as described

below.

The primary data sources used to develop the fossil-based plastic resin factors include:

• The Life-Cycle Inventory (LCI) report, Cradle-to-Gate Life Cycle Inventory of Nine Plastic Resins

and Four Polyurethane Precursors (FAL 2011), which provides raw material acquisition and

manufacturing energy data for the production of the virgin plastic resins HDPE, LDPE, PET,

LLDPE, PP, GPPS, and PVC. This report presents a cradle-to-gate LCI quantifying the total energy

requirements, energy sources, atmospheric pollutants, waterborne pollutants, and solid waste

resulting from the production of nine plastic resins produced in North America. (KEY)

• The LCI report, Life Cycle Impacts for Postconsumer Recycled Resins: PET, HDPE, and PP (FAL

2018), which provides process energy data for the production of recycled plastics resins HDPE,

PET, and PP. This report presents a cradle-to-gate life cycle analysis quantifying total emissions

from the production of recycled HDPE, PET, and PP resins in North America. (KEY)

The bioplastics factors rely largely on two primary data sources:

• The NatureWorks U.S. LCI spreadsheet entitled “SS Polylactide Biopolymer Resin_US LCI

May_2010.xls” submitted to the U.S. LCI Database

5

(U.S. LCI 2010). It provides raw material

acquisition and manufacturing energy data for the production of Ingeo PLA resin. Although this

source reflects PLA resin production by NatureWorks LLC in Blair, Nebraska, it is considered

representative of U.S. PLA production due to the absence of direct competitors to NatureWorks

operating a fully industrial-scale PLA manufacturing plant in the United States. (KEY)

• Responses from NatureWorks on ICF’s preliminary review of the NatureWorks PLA LCI Data

Memo (NatureWorks 2010). The responses include updated data for net atmospheric CO

2

uptake during corn production, landfill carbon storage, and PLA carbon content. (KEY)

Transportation-related information was obtained from the following data sources:

• For all plastics resins and bioplastics: US Census Commodity Flow Survey Preliminary Tables,

Table 1: Shipment Characteristics by Mode of Transportation for the United States (BTS 2013).

This source is a Commodity Flow Survey (CFS) on domestic freight shipments developed jointly

5

U.S. Life Cycle Inventory Database | NREL, https://www.nrel.gov/lci/

WARM Data Quality Assessment 17

by the Bureau of Transportation Services (BTS), the U.S. Census Bureau, and U.S. Department of

Commerce. It provides data on retail transportation distance and fuel-type.

• For bioplastics: The Role of Recycling in Integrated Solid Waste Management to the Year 2000

(FAL 1994). This report is a study on the role of recycling in integrated solid waste management

published by Franklin Associates and provides data on transportation energy use.

• For bioplastics: Evaluation of Climate, Energy, and Soils Impacts of Selected Food Discards

Management Systems (Oregon Department of Environmental Quality [DEQ] 2014). This report

evaluates the environmental and energy impacts of specific food discards management systems

and provides data on transportation emissions. The transportation emissions data from this

report are used for bioplastics.

Scoring. The average DQA scores for plastics and bioplastics varied within the medium to medium-high

data quality levels. A summary of the results by data quality indicator grouping for plastics and

bioplastics is shown in Table 7. The key findings for each of the sources used for plastics and bioplastics

are discussed below.

Table 7: Summary of Data Quality Results for Plastics and Bioplastics Data Sources

Material

DQ Values by Indicator Grouping

Flow Reliability

Flow

Represent-

ativeness

Process Review

and

Completeness

Average

Weighted

Average

Plastics

Medium-high

Medium-high

Medium

Medium-high

Medium-high

Bioplastics

Medium-high

Medium

Medium-high

Medium-high

Medium-high

Note: For details on the indicator subcategories for each indicator grouping, see Section 2: Approach.

Plastics

The medium-high data quality average and weighted average for the fossil-based plastic resins was

largely a consequence of the data from the virgin plastic resin LCI report (FAL 2011) reflecting medium-

high and high data quality for most flows and process indicators. The exception for that data source is

the process review indicator (a sub-category of the process review and completeness indicators), which

was deemed low quality due to lack of information on external reviews in that report and temporal

correlation (a sub-category of the flow representativeness indicator), which reflects medium-low data

quality due to the data used in FAL (2011) being representative of 2003 or earlier. The recycled plastic

resin LCI report (FAL 2018) was classified as medium to high data quality across the indicators as it

covers over 80 percent of processes in North America related to the emissions of recycling plastics, with

a representative data pool and documented calculation. The Role of Recycling Report (FAL 1994), which

provides general transportation equipment information, was determined to be of medium-high data

quality as it characterizes a majority of the municipal solid waste in the United States at the time, uses

calculated data, and covers a wide scope of technologies, including vehicle type, vehicle load, and

material type to inform data on transportation equipment. However, FAL (1994) is not a higher data

quality source due to low quality temporal correlation as the data were collected in 1992. This likely

impacts the validity of the data as transportation technology has changed since 1992. The Commodity

Flow Survey (BTS 2013) reflects medium data quality overall, as it was characterized as medium-low

data quality for temporal correlation and process review due to data that are over 10 years old and a

WARM Data Quality Assessment 18

lack of information on external reviews. The source also reflected low data quality for process

completeness (sub-category of process review and completeness indicators).

The plastic data sources generally reflect high data quality for flow reliability, geographical correlation,

and data collection (sub-categories of the flow representativeness indicators), and process

completeness indicators. However, the plastic data sources reflect low data quality for the temporal

correlation indicator (sub-category of the flow representativeness indicators) and process review

indicator. The mixed plastics material type in WARM is the average of the emission factors developed

for the plastic resins. Therefore, the average plastics data quality scoring was applied to assess the

“mixed plastics” material category.

Bioplastics

For bioplastics, the NatureWorks LCI dataset (U.S. LCI 2010) was characterized as having medium-high to

high data quality across the indicators, with the exception of the temporal correlation indicator, which

reflected medium-low quality. The additional NatureWorks source (Vink 2010) is of medium-high data

quality overall, as it was deemed high quality across most indicators, but low data quality for temporal

correlation and process review completeness (sub-category of process review and completeness

indicators) as it is a relatively old source and lacks documentation of external reviews. The data quality

of the additional data sources—BTS (2013), FAL (1994), Oregon DEQ (2014)—used for the PLA emission

and energy factors are described above under plastics.

Overall, the plastics datasets scored as follows:

• Average indicator: Medium-high

• Average weighted indicator: Medium-high

Overall, the bioplastics datasets scored as follows:

• Average indicator: Medium-high

• Average weighted indicator: Medium-high

Recommendations

Areas for improvement include:

• Identify and incorporate an additional source for raw material acquisition and manufacturing energy

data for the production of virgin plastic resins that has two or more types of documented third-party

reviews. The current source, FAL (2011), that provides process energy data for all virgin plastic resins

does not have any documented third-party reviews.

• Identify and incorporate an additional source for plastics with process data for production of

additional recycled plastic resins (i.e., LDPE, LLDPE, GPPS, and PVC). FAL (2018), the singular source

for data on recycled plastic resins, includes only HDPE, PET, and PP resins.

• Update the retail transportation distance and fuel-type information with the more recently available

US Census Commodity Flow Survey (from 2017).

WARM Data Quality Assessment 19

3.2 Metals

Summary of Key Findings

Data Sources. The types of metals modeled in WARM include aluminum cans, aluminum ingot, steel

cans, and copper wire. This WARM material category focuses on container and packaging end-uses for

aluminum and steel and electrical end-uses for copper wire. Metals can be employed in various sectors

and products; other major uses of aluminum in addition to those considered in WARM include

construction, consumer durables, electrical, machinery and equipment, transportation, and other

industrial uses. For steel, other major uses include service centers and distributors, construction (which

is modeled in WARM but discussed in the construction materials section below), transportation, and

other industrial uses. Other major uses of copper include building construction, industrial machinery and

equipment, transportation equipment, and consumer and general products. A mixed metals material

type is also modeled in WARM, reflecting the weighted average using the latest relative recovery rates

for steel and aluminum cans. See column I of Table 8 below for these recovery rates. See the “Mixed

Metals” material in Table 9 below for data quality scoring that follows this weighting scheme.

Table 8. Relative Prevalence of Metals in the Waste Stream in 2015

(a)

(I(c)

(d)

(e)

(f)

Material

Generation

(Short Tons)

% of Total

Container

Metal

Generation

Recovery

(Short Tons)

% of Total

Metals

Recovery

Recovery Rate

Aluminum Cans

1,350,000

43%

670,000

35%

50%

Aluminum Ingot

NA

NA

NA

NA

NA

Steel Cans

1,740,000

57%

1,240,000

65%

71%

Copper Wire

NA

NA

NA

NA

NA

Source: EPA (2018).

NA = Not available.

The WARM emission and energy factors for these metals rely on 9 primary data sources. For the

development of the aluminum can and aluminum ingot factors, the primary data sources include:

• The LCA report, Life Cycle Impact Assessment of Aluminum Beverage Cans (PE Americas 2010),

which provides process and process non-energy data for aluminum beverage cans.

6

It is used to

develop the process and process non-energy emission factors for aluminum cans and aluminum

ingot and to understand the current mix of inputs (recycled vs. virgin) for WARM. This source

was further disaggregated by process energy, transportation energy, and non-energy process

emissions for WARM by the Aluminum Association in a spreadsheet provided to ICF and EPA (PE

Americas 2011). (KEY)

6

The Aluminum Association provided a detailed spreadsheet of their calculations (titled "Data for ICF-EPA_ICF

formatted 08-04-11”) to supplement the information published in the PE Americas report. ICF had several

conversations with Senior Sustainability Specialist, Jinlong Marshall Wang to clarify the details in the calculations’

spreadsheet. Because this spreadsheet is considered an extension of the PE Americas report, the calculation

spreadsheet was not assessed for data quality separately from the PE Americas report (2010).

WARM Data Quality Assessment 20

• An unpublished database with transportation energy data developed jointly by the Research

Triangle Institute and EPA (RTI 2004). It documents energy consumption associated with virgin

and recycled production process transportation across material types and is used to develop the

transportation energy emissions factor for aluminum.

The primary data sources used to develop the steel can factors include:

• The EPA report, Background Document A: A Life Cycle of Process and Transportation Energy for

Eight Different Materials, Greenhouse Gas Emissions from Management of Selected Materials in

Municipal Solid Waste, prepared by Franklin Associates, Ltd. (EPA 1998a). This report provides

process energy, process non-energy and transportation energy data for steel cans. (KEY)

• Personal communication between ICF and Franklin Associates, Ltd. that culminated in a

documented review of recycled content values and current mix of steel can production

(identifying the percentage that is from recycled versus virgin inputs) (FAL 2003a). The

communications information was based on two key resources: Ohio Department of Natural

Resources “Full Circle: Buying Recycled-Content Products” fact sheet,

7

and “Municipal Solid

Waste in the United States: 2000 Facts and Figures” document

8

developed by the EPA.

• Loss rate data provided by Franklin Associates, Ltd. (FAL 2003b).

The primary data sources used to develop the copper wire factors include:

• The report, Energy and Greenhouse Gas Factors for Personal Computers, prepared by Franklin

Associates, Ltd. (FAL 2002). It presents life-cycle energy and GHG emissions for personal

computers, including the GHG emissions associated with relevant copper production for use in

computers. It provides the process energy, process non-energy, and transportation energy data

used for the copper wire emission factors. (KEY)

• The report, Flows of Selected Materials Associated with World Copper Smelting, prepared by the

U.S. Geological Survey (USGS 2004) that provides information on the percent of current

production from recycled vs. virgin inputs for copper wire, and the copper wire scrap mix used

to create copper ingot.

For all metals, transportation-related information was obtained from the following data sources:

• The EPA report, Greenhouse Gas Emissions from the Management of Selected Materials (1998b),

which provides retail transportation

9

energy data used for the aluminum and steel calculations.

This is the predecessor to the WARM documentation and bases its retail transportation energy

on data received from Franklin Associates (FAL 1998) and the Tellus Institute (Tellus 1998) in

7

Ohio Department of Natural Resources. Full Circle: Buying Recycled-Content Products.

www.dnr.state.oh/us/recycling/awareness/facts/buy.htm.

8

Municipal Solid Waste in the United States: 2000 Facts and Figures. EPA530-R-02-001. Also, Franklin Associates, A

Division of ERG, working papers for this report and previous versions.

9

“Retail transportation” consists of the average truck, rail, water and other-modes transportation emissions

required to get the material from the manufacturing facility to the retail/distribution point.

WARM Data Quality Assessment 21

Background Documents A and B, respectively. The Franklin Associates Background Document A

provides the aggregated process and transportation energy for eight materials, including

aluminum and steel cans. The Tellus Institute Background Document B estimates the amounts

and types of energy consumed in raw materials acquisition and manufacturing of eight

materials, including aluminum and steel cans.

• US Census Commodity Flow Survey Preliminary Tables, Table 1: Shipment Characteristics by

Mode of Transportation for the United States (BTS 2013). This source is a CFS on domestic

freight shipments developed jointly by the BTS, the U.S. Census Bureau, and U.S. Department of

Commerce. It provides data on retail transportation distance and fuel-type.

Scoring. This DQA showed that data quality is generally consistent across all metals with an average and

weighted individual value of medium. Only the flow reliability and process review and completeness

indicators and average value for steel cans are rated differently, with a medium-low values. While the

DQA values varied across individual data sources, overall, all metals materials received an average value

that corresponds with the medium data quality level. On average, the metal sources scored the best in

the geographical correlation indicator category. For that indicator, the sources had medium-high data

quality, conveying that the region of data correlates well to that of WARM (i.e., the United States). A

summary of the results by DQI is shown in Table 9. The key findings for each of the sources used for the

different metal materials are discussed below.

Table 9: Summary of Data Quality Results for Metal Data Sources

Material

DQ Values by Indicator Grouping

Flow Reliability

Flow

Represent-

ativeness

Process Review

and

Completeness

Average

Weighted

Average

Aluminum Cans &

Aluminum Ingot

Medium

Medium

Medium

Medium

Medium

Steel Cans

Medium-low

Medium

Medium-low

Medium-low

Medium

Copper Wire

Medium

Medium

Medium

Medium

Medium

Mixed Metals

Medium

Medium

Medium

Medium

Medium

Metals

Medium

Medium

Medium

Medium

Medium

Note: For details on the indicator subcategories for each indicator grouping, see Section 2: Approach.

Aluminum Cans and Aluminum Ingot

The PE Americas (2010)

10

report along with the PE Americas (2011) spreadsheet had the highest data

quality among the metal data sources reviewed, showing a medium-high data quality. This result is due

to its strong geographical and technological correlation, flow reliability, process completeness, and

process review. The PE Americas (2010) report also developed its own rating using the same general

10

To develop the life-cycle process emission factors for aluminum, the PE Americas report uses WRI fuel emission

factors, global average grid emission factors (for bauxite mining and alumina refining); North America aluminum

industry mix and global aluminum industry mix (for smelting and casting) values; and the United States average

grid emission factors (for secondary production, can sheet rolling, and can making). These distinct calculation

inputs for the PE Americas report emission factors were sent to ICF in the “Data for ICF-EPA_ICF formatted 08-04-

11” spreadsheet. Because these are inputs to the PE Americas report, the rating for the PE Americas report is

reflective of these input sources as well.

WARM Data Quality Assessment 22

scoring metric as this report (see Appendix: Data Quality Assessment Matrix). There were additional

conversations with Marshall Wang of the Aluminum Association that also informed the development of

the process and process non-energy emission factors, but this information was included in the

supplemental spreadsheet provided to ICF and EPA (PE Americas 2011), which was assessed collectively

for the purposes of the DQA.

The RTI (2004) database that is used to develop the transportation energy emissions factor for

aluminum received a low data quality value. This is due to the age of the data, reducing the temporal

correlation, and limited to no documentation on the other data quality indicators. Details on the

development of and methodology for this database also could not be located, leading to the low data

quality value.

The scoring for EPA (1998b) was based on an average of the data quality values for both the Franklin

Associates and the Tellus Institute Background Documents (see Table 10 below). It received an average

value of medium-high due to its high quality process completeness and geographical and technological

correlation. Its data quality was lowest for temporal correlation and sample size because much of the

data were uncited, and the source is over 20 years old.

Table 10: EPA 1998b Background Document Ratings

Source

Flow Reliability

Flow

Representativeness

Process Review and

Completeness

FAL (1998) Background Document A

Medium-High

Medium

Medium-High

Tellus (1998) Background Document B

Medium-High

Medium

High

EPA 1998b (average of background

documents)

Medium-high

Medium

High

The Commodity Flow Survey (BTS 2013) has medium data quality overall. Its lowest data quality value is

for process completeness, and averages as medium for its flow representativeness. EPA (2018a) has an

average value of medium-low due to its high data quality across most categories, except for process

review.

Steel Cans

The EPA report, Background Document A: A Life Cycle of Process and Transportation Energy for Eight

Different Materials report (EPA 1998a), had high data quality for geographical correlation, technological

correlation, and process completeness because its data were representative of the United States, its

technology categories were equivalent, and it covered greater than 80 percent of the determined

process flows. EPA (1998a) received low data quality values for temporal correlation, as the source is

greater than 15 years old, and data generation and collection methods, as explanations were not found.

While there were third party reviews of the EPA (1998a) document, documented reviews of the Franklin

Associates data were not found, which impacted its process review data quality value.

The FAL (2003a) source, providing information on the current mix of steel can production received an

average value of medium-low, with low data quality for temporal correlation. This is because it is based

on data that are more than 15 years old, and low data quality for representativeness and process review

WARM Data Quality Assessment 23

and completeness as the sample size of the data is unknown, and there are no documented reviews of

the data. Because the information in FAL (2003a) is based on two key resources: Ohio Department of

Natural Resources “Full Circle: Buying Recycled-Content Products” fact sheet, and EPA’s “Municipal Solid

Waste in the United States: 2000 Facts and Figures” document, the scoring for FAL (2003a) was the

average of the scoring given to those sources. The Ohio Department of Natural Resources fact sheet was

not located, and thus was given a scoring of low data quality for each DQI category.

The FAL (2003b) source, providing the material loss rate information for steel cans, was not located, and

therefore was given low data quality scoring across all categories. The scoring for EPA (1998b), BTS

(2013), and EPA (2018a) are discussed in the aluminum can and ingot section above.

Copper Wire

FAL (2002) reflected a medium data quality value on average based on its mix of DQI values from low to

high quality. It had low data quality for temporal correlation, as much of the data are more than 15

years old, and for process completeness and data collection methods due to those aspects being

unknown and unable to assess. This source had medium-low data quality for flow reliability because it is

an old source with data based on documented estimates rather than verified measurements of

calculations. However, FAL (2002) had high data quality for geographical correlation, as the data are

U.S.-based, and medium-high quality for technological correlation and process review. Because

technology processes are slower to change, older data are not necessarily unrepresentative of the

current production and processing landscape. However, the data quality scoring matrix takes a cautious

approach by giving lower quality values to older data sources, in case the material type has a quicker

technological progress timescale.

The USGS (2004) source had an average data quality level of medium. Its lowest data quality is for

process completeness, and its highest data quality is for flow reliability, geographical correlation, and

technological correlation.

11

The scoring for EPA (1998b) and BTS (2013) are discussed in the aluminum

can and ingot section above.

Overall, the metals datasets scored as follows:

• Average indicator: Medium

• Average weighted indicator: Medium

Recommendations

Areas for improvement include:

• Identify and incorporate data on energy consumption from a more recent and publicly published

study. WARM currently pulls from the RTI (2004) database, which is over 15 years old and has the

lowest data quality of all the sources. As the dataset is unpublished, there is very little information

on its methodology which contributes to its low data quality.

11

See the USGS methodology report for more information on the rating: https://d9-wret.s3.us-west-

2.amazonaws.com/assets/palladium/production/s3fs-public/atoms/files/myb1-2004-surve-2.pdf

WARM Data Quality Assessment 24

• Identify and incorporate more recent data, particularly for steel and copper wire, to replace sources

such as EPA (1998a) and FAL (2002). Compared to other material categories, metal sources had the

lowest data quality in the temporal correlation category, with an overall medium-low level,

conveying that the data sources are on average greater than 15 years old. Because many

technologies are slower to change, older data may still be relevant for many processes. However,

there is still a clear need to update the data sources used in WARM for the metals section to studies

based on more recent datasets.

• Update the retail transportation distance and fuel-type information with the more recently available

US Census Commodity Flow Survey (from 2017).

• Assess the feasibility of updating the aluminum factors with data from a more recent assessment.

12

• Retain documentation for all data sources, including conversations with subject matter experts. Ask

subject matter experts that inform WARM to share published sources for any specific data elements.

3.3 Glass

Summary of Key Findings

Data Sources. The glass emission and energy factor calculations rely on two key data sources for process

energy and process non-energy emission factors and four key data sources for the transportation

emission factor calculations.

The primary data sources used for glass process energy and process non-energy data include:

• A database with process energy and process non-energy data developed jointly by the Research

Triangle Institute and EPA (RTI 2004). Process energy and process non-energy data are sourced

from this unpublished database that documents energy consumption associated with virgin and

recycled production processes across material types. (KEY)

• A U.S. Department of Energy (DOE) report, Energy and Environmental Profile of the U.S. Glass

Industry. DOE (2002), which provides assumptions on the average composition of glass and fuel

used to combust glass. This source provides an energy and environmental profile of the U.S.

glass industry.

• In-house data from Franklin Associates (FAL 2003b) provides information on the current mix of

production from virgin and recycled inputs for glass manufacturing, typical glass recycled

content values in the marketplace, and glass loss rates.

The primary data sources used for the transportation emission calculations include:

12

Wang 2022. "The Environmental Footprint of Semi-Fabricated Aluminum Products in North America." The

Aluminum Association. January 2022. https://www.aluminum.org/sites/default/files/2022-01/2022_Semi-

Fab_LCA_Report.pdf (Accessed: January 17, 2023).

WARM Data Quality Assessment 25

• The Role of Recycling in Integrated Solid Waste Management to the Year 2000 (FAL 1994). This

report is a study on the role of recycling in integrated solid waste management published by

Franklin Associates. This report provides GHG emissions from transportation energy usage for

transportation of waste to the combustion facility.

• US Census Commodity Flow Survey Preliminary Tables, Table 1: Shipment Characteristics by

Mode of Transportation for the United States (BTS 2013). This source is a Commodity Flow

Survey (CFS) on domestic freight shipments developed jointly by the Bureau of Transportation

Services (BTS), the U.S. Census Bureau, and U.S. Department of Commerce. It provides

additional assumptions on retail transportation energy usage (average shipping distances and

modes) for glass.

• Typical transportation fuel efficiencies are sourced from the EPA report, Greenhouse Gas

Emissions from the Management of Selected Materials, prepared by ICF for EPA, (EPA 1998b),

which is the original WARM emission factor methodology document.

Scoring. On average, the data quality for the glass data sources is highest within the geographical and

technological correlation indicators. On average, the sources reflect medium data quality, conveying

that the region of data correlates relatively well to that of WARM (the United States) and the majority of

technology categories are equivalent.

13

The low data quality of the key source for the glass analysis

brought down the weighted average value to medium-low. A summary of the results by data quality

indicator groupings is shown in Table 11. The key findings for each of these sources are discussed below.

Table 11: Summary of Data Quality Results for Glass Data Sources

Material

DQ Values by Indicator Grouping

Flow

Reliability

Flow

Representative

-ness

Process

Review and

Completeness

Average

Weighted

Average

Glass

Medium

Medium

Medium

Medium

Medium-low

Note: For details on the indicator subcategories for each indicator grouping, see Section 2: Approach.

RTI (2004) was considered to be a low quality source as it is an unpublished database developed by the

Research Triangle Institute and EPA; and details on the development of and methodology for that

database have not been found. This is especially salient as the process energy and non-process energy

emission factors for glass is almost entirely based on RTI (2004), with additional glass composition

assumptions sourced from DOE (2002). The highest data quality was with FAL (1994), which includes a

fairly robust dataset; however, the data collection occurred in 1992.

FAL (2003a) is based on in-house data provided by Franklin Associates to ICF. This source was not found

as it is based on in-house data from Franklin Associates, and therefore was considered to reflect low

data quality across all categories.

13

Technology categories are process design, operating conditions, material quality, and process scale.

WARM Data Quality Assessment 26

For the development of the weighted average glass data quality value, the RTI (2004) data source is

weighted more heavily than the rest of the sources as it is the main source of process energy and

process non-energy data used for the development of WARM glass emission and energy factors.

Overall, the glass datasets scored as follows:

• Average indicator: Medium

• Average weighted indicator: Medium-low

The difference between the medium quality average indicator value and the medium-low quality

average weighted indicator value shows the impact of a key data source being low quality. RTI (2004)

was determined to be a low quality, out of date source with a poorly documented methodology.

However, WARM relies on RTI (2004) as a key source to inform glass emissions, which brings down the

overall quality of the glass section, particularly when considering an average that weighs RTI (2004)

more heavily than other sources.

Recommendations

Areas for improvement include:

• Conduct research to identify a more recent peer-reviewed study for the glass process energy

emission factors than the current data source, RTI (2004). On average, the data quality for the glass

data sources is lowest within the temporal correlation category.

• Identify more recent and publicly available information on the current mix of production for glass.

• Update the retail transportation distance and fuel-type information with the more recently available

US Census Commodity Flow Survey (from 2017).

• Consider a more updated source for transportation fuel efficiencies (such as fuel efficiencies

published by NREL

14

).

3.4 Paper

Summary of Key Findings

Data Sources. Paper materials and products included in WARM are magazines, newspaper, office paper,

phonebooks, textbooks, and corrugated containers such as cardboard packing boxes. The paper material

emission factor and energy factor calculations rely on seven data sources. Of these, three key data

sources informed process energy, process non-energy, and transportation emission factors, and

therefore were weighted more heavily when determining overall data quality of paper sources. These

include:

• An unpublished database developed jointly by the Research Triangle Institute and the U.S.

Environmental Protection Agency Office of Research and Development (RTI 2004), which

provides information on the industrial process emissions and energy mix of paper materials

including corrugated containers, magazines, newspaper, office paper, phonebooks, and

textbooks. (KEY)

14

Alternative Fuels Data Center: Maps and Data - Average Fuel Economy by Major Vehicle Category (energy.gov)

WARM Data Quality Assessment 27

• The EPA Report, Greenhouse Gas Emissions from Management of Selected Materials in

Municipal Solid Waste, Background Document A: A Life Cycle of Process and Transportation

Energy for Eight Different Materials, prepared by Franklin Associates, Ltd. (EPA 1998a), which

provides information on energy requirements for production of recycled corrugated containers.

(KEY)

• Greenhouse Gas Emissions from Management of Selected Materials in Municipal Solid Waste,

Background Document A, Attachment 1: A Partial Life Cycle Inventory of Process and

Transportation Energy for Boxboard and Paper Towels, published by Franklin Associates, Ltd.

(FAL 1998), which provides information on the composition of mixed paper and energy

requirements for production of virgin and recycled boxboard. (KEY)

The paper factors also relied on other non-key data sources:

• Personal communication between ICF and Franklin Associates, Ltd. that culminated in a

documented review of recycled content values and current mix of paper material production

(identifying the percentage that is from recycled versus virgin inputs) (FAL 2003a).

• In-house data from Franklin Associates (FAL 2003b) provides information on retention rates

during recycling of paper materials.

• U.S. Census Commodity Flow Survey Preliminary Tables, published by the U.S. Bureau of

Transportation Statistics (BTS) Research and Innovative Technology Administration (BTS 2013),

which provides data on transportation energy.

• Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990 – 2013, a report published by the

U.S. EPA (EPA 2015), which provides measurements on fuel-specific carbon content and

coefficients.

Scoring. A summary of the results by data quality indicator groupings is shown in Table 12. The key

findings for each of these sources are discussed below.

Table 12: Summary of Data Quality Results for Paper Data Sources

Material

DQ Values by Indicator Grouping

Flow

Reliability

Flow

Represent-

ativeness

Process

Review and

Completeness

Average

Weighted

Average

Paper

Medium-low

Medium

Medium-low

Medium-Low

Medium

Note: For details on the indicator subcategories for each indicator grouping, see Section 2: Approach.

Key sources for paper, RTI (2004), EPA (1998a), and FAL (1998), provide process energy, process non-

energy, and transportation energy requirements for the manufacturing of various paper materials.

Overall, the paper flow representativeness indicator reflected medium data quality, while the flow

reliability and process review and completeness indicators reflected medium-low data quality. On

average, the paper data sources were of low quality for temporal correlation; medium-low for flow

reliability, data collection methods, and process review; and medium quality for geographical

correlation, technological correlation, and process completeness. Poor temporal correlation was due to

WARM Data Quality Assessment 28

the publication years of the paper data sources, which range from 1998 to 2015. Data collection

methods saw more variable data quality, but two sources, including key source RTI (2004) and EPA

(1998a), were deemed low quality for this category as the sources did not list sites or time periods