Third

Edition

Metric Version

www.iscar.com

www.iscar.com

ISCAR’s Quick

Reference Guide for

Die and Mold Making

ISCAR’s Quick

Reference Guide for

Die and Mold Making

ISCAR’s Quick Reference Guide for Die and Mold Making Metric Version

ISCAR LTD.

Headquarters

Tefen 24959, Israel

Tel + 972 (0)4 997 0311

Fax + 972 (0)4 987 3741

www.iscar.com

Argentina

ISCAR TOOLS ARGENTINA SA

Monteagudo 222

1437 Buenos Aires

Tel + 54 114 912 2200

Fax + 54 114 912 4411

Australia

Headquarters and Technical Centre

Norwest Business Park

30 Brookhollow Avenue

Baulkham Hills NSW 2153

Australian Technical Training Centre

Bell Street, Preston, Victoria, 3072

Tel + 61 (0) 2 8848 3500

Fax + 61 (0) 2 8848 3511

www.iscar.com.au

Austria

ISCAR AUSTRIA GmbH

Im Stadtgut C 2

A-4407 Steyr-Gleink

Tel + 43 7252 71200-0

Fax + 43 7252 71200-999

www.iscar.at

Belarus

JV ALC “TWING-M”

Slutskaya str. 3,

223056 v. Sennitsa

Minsk district

Tel +375 17 506-32-38

+375 17 506-33-31/65

Tel/Fax +375 17 506-32-37

www.twing.by, www.iscar.by

Belgium

n.v. ISCAR BENELUX s.a.

Roekhout 13

B 1702 Dilbeek (Groot-Bijgaarden)

Tel + 32 (0) 2 464 2020

Fax + 32 (0) 2 522 5121

www.iscar.be

Bosnia

(Representative Office)

Kralja Tvrtka I br. 17

BIH- 72000 Zenica

Tel +387 32 201 100

Fax +387 32 201 101

Brazil

ISCAR DO BRASIL COML. LTDA.

Rodovia Miguel Melhado Campos,

Km 79, Bairro Moinho

CEP: 13280-000 - Vinhedo - SP

Tel + 55 19 3826-7100

Fax + 55 19 3826-7171

DDG 0800 701 8877

www.iscar.com.br

Bulgaria

ISCAR BULGARIA

Starozagorska 1, Str.

Floor 1, Office G,

6100 Kazanlak

Tel/Fax +359 431 62557

Canada

ISCAR TOOLS INC.

2100 Bristol Circle

Oakville, Ontario L6H 5R3

Tel + 1 905 829 9000

Fax + 1 905 829 9100

www.iscar.ca

China

ISCAR CHINA

7B21, Hanwei Plaza,

7 Guanghua Road

Chaoyang District

Bejiing 100004

Tel + 86 10 6561 0261/2/3

Fax + 86 10 6561 0264

www.iscar.com.cn

Croatia

ISCAR ALATI d.o.o.

J. Jelačiča 134

CRO-10430 Samobor

Tel +385 (0) 1 33 23 301

Fax +385 (0) 1 33 76 145

www.iscar.hr

Czech Republic

ISCAR CR s.r.o.

Mánesova 73, 301 00 Plzen

Tel + 420 377 420 625

Fax + 420 377 420 630

www.iscar.cz

Finland

ISCAR FINLAND OY

Ahertajantie 6

02100 Espoo

Tel +358-(0)9-439 1420

Fax +358-(0)9-466 328

France

ISCAR FRANCE SAS

8, Rue Georges Guynemer

78286 GUYANCOURT Cedex

Tel + 33 (0)1 30 12 92 92

Fax + 33 (0)1 30 43 88 22

www.iscar.fr

Germany

ISCAR GERMANY GmbH

Eisenstockstrasse 14

D 76275 Ettlingen

Tel + 49 (0) 72 43 9908-0

Fax + 49 (0) 72 43 9908-93

www.iscar.de

Hungary

ISCAR HUNGARY kft

Kassai u 151

H 1142 Budapest

Tel + 36 1 251 5688

Fax + 36 1 251 4757

www.iscar.hu

Italy

ISCAR ITALIA srl

Via Mattei 49 / 51

20020 Arese [MI]

Tel + 39 02 93 528 1

Fax + 39 02 93 528 213

www.iscaritalia.it

Japan

ISCAR JAPAN LTD.

Head Office

15th Floor, Senri Asahi

Hankyu Building

1-5-3, Shinsenri-Higashimachi

Toyonaka-Shi,

Osaka 560-0082

Tel + 81 6 6835 5471

Fax + 81 6 6835 5472

www.iscar.co.jp

Macedonia

(Representative Office)

Londonska 19/4

MK-1000 Skopje

Tel +389 2 309 02 52

Fax +389 2 309 02 54

Mexico

ISCAR DE MÉXICO,

S.A de C.V.

Fray Pedro de Gante 15

Col. Cimatario

Querétaro, Qro.

C.P. 76030

Tel + 52 (442) 214 5505

Fax + 52 (442) 214 5510

www.iscar.com.mx

The Netherlands

ISCAR NEDERLAND B.V.

Postbus 704, 2800 AS Gouda

Tel + 31 (0) 182 535523

Fax + 31 (0) 182 572777

www.iscar.nl

New Zealand

ISCAR PACIFIC LTD.

1/501 Mt. Wellington Hwy.

Mt. Wellington Auckland

Tel + 64 9 5731280

Fax + 64 9 5730781

Poland

ISCAR POLAND Sp. z o.o.

ul. Gospodarcza 14

40-432 Katowice

Tel + 48 32 735 7700

Fax + 48 32 735 7701

www.iscar.pl

Portugal

ISCAR

PORTUGAL, SA

Avd.Dr.Domingos Caetano de Sousa

Fracção B, Nº 541

4520-165 Santa Maria da Feira

Tel + 351 256 579950

Fax + 351 256 586764

www.iscarportugal.pt

Romania

ISCAR TOOLS SRL

Str. Maramures nr. 38,

Corp 2, Otopeni,

jud. Ilfov, cod 010832

Tel + 40 (0)312 286 614

Fax + 40 (0)312 286 615

Russia

Moscow

ISCAR RUSSIA CIS

Godovikova str. 9, build. 10

129085 Moscow

Tel/fax +7 495 660 91 25/31

www.iscar.ru

Chelyabinsk

ISCAR RF EAST LTD

Malogruzovaya str., 1 - office 605

454007, Chelyabinsk

Tel/fax +7 351 2450432

www.iscar.ru

Serbia

ISCAR TOOLS d.o.o.

Autoput 22

SRB-11080 Zemun

Tel +381 11 314 90 38

Fax +381 11 314 91 47

Slovakia

ISCAR SR, s.r.o.

K múzeu 3

010 03 Zilina

Tel +421 (0) 41 5074301

Fax +421 (0) 41 5074311

www.iscar.sk

Slovenia

ISCAR SLOVENIJA d.o.o.

IOC, Motnica 14

SI-1236 Trzin

Tel + 386 1 580 92 30

Fax + 386 1 562 21 84

www.iscar.si

South Africa

ISCAR SOUTH AFRICA (PTY) LTD.

47 Lake Road

Longmeadow Business Estate - North

Extension 7, Modderfontein,

Edenvale, Gauteng

P.O. Box 392

Longmeadow Business Estate - North 1609

ShareCall 08600-47227

Tel +27 11 997 2700

Fax +27 11 388 9750

www.iscar.co.za

South Korea

ISCAR KOREA

304 Youggye-Ri,

Gachang-myeon

Dalsung-gun, Daegu 711-860

Tel + 82 53 760 7590

Fax + 82 53 767 7203

www.iscarkorea.co.kr

Spain

ISCAR IBERICA SA

Parc Tecnològic del Vallès

Avda. Universitat Autònoma 19-21

08290 Cerdanyola-Barcelona

Tel +34 93 594 6484

Fax +34 93 582 4458

www.iscarib.es

Sweden

ISCAR SVERIGE AB

Kungsangsvagen 17B

Box 845

751 08 Uppsala

Tel + 46 (0) 18 66 90 60

Fax + 46 (0) 18 122 920

www.iscar.se

Switzerland

ISCAR HARTMETALL AG

Wespenstrasse 14

CH 8500 Frauenfeld

Tel + 41 (0) 52 728 0850

Fax + 41 (0) 52 728 0855

www.iscar.ch

Taiwan

ISCAR TAIWAN LTD.

395, Da Duen South Road,

Taichung 408

Tel +886 (0)4-24731573

Fax +886 (0)4-24731530

www.iscar.org.tw

Thailand

ISCAR THAILAND LTD.

57, 59, 61, 63 Soi Samanchan-Babos

Sukhumvit Rd.

Phra Khanong, Khlong Toey

Bangkok 10110

Tel + 66 (2) 7136633-8

Fax + 66 (2) 7136632

Turkey

ISCAR KESICI TAKIM

TIC. VE IML. LTD. STI.

Gebze Organize Sanayi Bölgesi (GOSB)

Ihsan Dede Cad. No: 105

Gebze / Kocaeli

Tel + 90 (262) 751 04 84 (Pbx)

Fax + 90 (262) 751 04 85

www.iscar.com.tr

Ukraine

ISCAR UKRAINE LLC

Volgodonska str., 66

02099 Kiev

Tel/fax +38 (044) 503-07-08

www.iscar.ru

United Kingdom

ISCAR TOOLS LTD.

Woodgate Business Park

Bartley Green

Birmingham B32 3DE

Tel + 44 (0) 121 422 8585

Fax + 44 (0) 121 423 2789

www.iscaruk.co.uk

United States

ISCAR METALS INC.

300 Westway Place

Arlington, TX 76018-1021

Tel + 1 817 258 3200

Tech Tel 1-877-BY-ISCAR

Fax + 1 817 258 3221

www.iscarmetals.com

Vietnam

ISCAR VIETNAM

(Representative Office)

Room D 2.8, Etown Building,

364 Cong Hoa, Tan Binh Dist.,

Ho Chi Minh City

Tel +84 38 123 519/20

Fax +84 38 123 521

7861458

© ISCAR LTD.

All rights reserved

02/2017

Dear Die and Mold Maker,

our Distinguished Customer and Colleague,

Our primary concern, as a tool manufacturer, is to provide you with the most progressive and most

high-efficiency cutting tools that will meet your requirements and answer the purpose of

modern technology.

Cutting metal faster and more accurate means cutting machining time and cost per part.

In many cases the cutting tool, which is sometimes seen as the more insignificant link in the chain

of production costs, presents a barrier to achieving productivity. We, at ISCAR, are aware of that

fact; and our ongoing research and development intends to develop those cutting tools that will

increase your manufacturing productivity, improve the performance of your workshop and lead

your die-making process to be more profitable.

The research and development result in various innovative solutions that we offer to our customers.

The variety of ISCAR tools is very rich, and sometimes, it is not so simple to be well oriented

in it. Therefore, we hope that this guide will help you in right tool selection and will be a good

supplement to our catalogs, reference forms and leaflets because it takes into account specific

features of die and mold making. First of all the guide emphasizes the latest solutions in order to

give you the opportunity of becoming familiar with them.

Also, we included here some more general information, tips and even historical issues related to

the discussed material and hope that you will find them useful.

We will be thankful for your every remark or suggestion regarding the guide.

We consider ourselves as your true colleague in the die and mold making process at your location

and will be proud and sincerely pleased if you will feel the same.

Die and Mold

3

Contents

Foreword ......................................................................................................

Die and Mold Materials ...............................................................................

Typical Examples of Dies and Molds ..........................................................

Cutting Tools in the Die and Mold Industry .................................................

Milling Tools ..................................................................................................

1. 90˚ Shoulder Milling ....................................................................

2. Milling Plane Surfaces ................................................................

3. Milling Contoured Surfaces (Profiling) .........................................

Hole Making Tools ........................................................................................

In Summation ................................................................................................

Technical Information ...................................................................................

3

4

8

9

10

13

36

44

119

121

122

4

ISCAR Tool Families

Referenced in this Guide

1. Milling Tools

2. Hole Making Tools

Foreword

Die and Mold

5

Foreword

A lot of things around us, parts or even fully completed products, are produced in dies and

molds: an internal cylinder block or a toy, a plastic container or a crankshaft, a bottle or a jet

turbine blade, a tin soldier or a boat. These objects differ in their form, material, sizes, mechanical

properties, and are manufactured by different technological methods of metal forming or

processing of plastics.

Broadly speaking a die or a mold, being an assembly unit, comprises various elements, and

many of them are standard or unified. A form of a part that is produced in the die or the mold

is determined by several main components (cavities, rams, etc.).

Shaping the components is a central operation in die and mold manufacturing that demands from

die and mold makers rich knowledge, skills and experience. A die and mold maker is rightfully

considered as one of the most professionally skilled workers in manufacturing. Modern CNC

technology and CAD/CAM systems substantially change die and mold making, turning it from

craft into a whole branch of trade.

A part intended to be produced in a die or mold dictates shape and sizes of the die or

mold and accuracy requirements; and a forming technology and the part run size – the die

or mold material. The part shape and the die or mold material are a source data for

die and mold making.

Automotive Industry is a major consumer of dies and molds. Approximately 60%

of stamping dies and 40% of plastic molds produce automotive parts.

There are different kinds of dies and molds, which can be grouped in the following principal

types: forging dies, stamping (pressing) dies, die casting dies and molds for plastics.

In manufacturing a die or mold, the shape and the sizes are the main factors of the degree

of difficulty for machining:

• Low degree in case of plane areas, simple shapes, shallow cavities etc.

• Medium, when the shape becomes more complicated, the sizes bigger and the cavities

deeper; rams have steep walls, etc.

• High degree in the context of very complex shape, narrow and deep cavities, considerable

difference between heights, etc.

Also, difficulty in machining is a function of machinability of the die or mold material.

The key to productive and effective die and mold making is the process planning – the choice

of technology of the die or mold manufacturing that, in general, includes machining

operations, assembly and finishing works. Today’s CAD/CAM software enables analyzing the

die or mold design, defining machining strategy, developing CNC programs and machining

simulation in order to find the most efficient solution that allows full use of advantages of

modern machine tools.

The right machining strategy is directly related to correctly chosen cutting tools that

perform material removal during operation. A tool, which seems to be a secondary element

of the die and mold process, is a substantial factor of productivity and profitability.

We, at ISCAR, distinctly understand the role of cutting tools in the die and mold industry and try

to provide the die and mold maker with reliable and efficient tooling that meets every

requirement of the branch. The right tool selection depends on different factors.

We will discuss them here briefly, explain the tools’ features and thus build a base

for the correct tool choice.

Die and Mold Materials

6

Die and Mold Materials

We have already noticed that a die or mold has different movable and stationary parts

(clamping elements, springs, pins, bolts, bushings, support pillars, etc.) generally made from

different engineering materials, from plastics to cemented carbides.

However, key die or mold parts that act on specific requirements of the die and mold industry

usually are from particular materials, which should be emphasized.

Tool Steels

Tool steels relate to a type of steels that, as indicated in its name, is intended first of all for

making tools for cutting and forming metals and other materials. There are many national and

international standards for specified tool steels. Moreover, in order to answer to the particular

requirements of industry, steel manufacturers produce different steels in accordance with their

own specification. These steels often have no standard designation and are identified by their

trade names. In this guide we use the standards of the American Iron and Steel Institute (AISI)

and the Society of Automotive Engineers (SAE). The parallel designation in conformity

with other acting standards is sometimes given in the text; and the information section at the

end of this guide contains a cross-reference table with comparative designation of tool steels

in keeping with the different national standards.

Die and mold makers deal with steel in wide ranges of hardness, from low (HB 200 and less)

to high (HRC 63).

In line with the main field of application there are six general and two special-purpose classes

of tool steels, from which the following are the most popular in the die and mold industry:

• Cold-work tool steels including A series (air-hardening medium-alloy),

D series (high-carbon high-chromium) and O series (oil hardening)

• Hot-work H series

• Water hardening W series

• Plastic mold P series

• Shock resistant S series

• Special-purpose L series (low-alloy)

In die and mold design, the main properties of tool steels are strength, wear resistance,

corrosion resistance, etc. However, while for a die and tool maker dealing with the material,

which has already been specified by designers, more important properties are: hardness,

machinability, polishability and dimensional stability.

The steel manufacturers supply steels in different delivery conditions: annealed, pre-hardened

and hardened. Consequently, in die and mold making process, hardness of tool steel

(even the same grade) can vary within a wide range from HB 200 and less (soft steel)

to HRC 63 (hard steel). Normally, high stock removal rate characterizes rough machining of

a soft material while closed allowances are usual for finish cuts when material hardness is high.

The term “pre-hardened steel” is not well-defined. It means that steel is hardened and tempered

to relatively not high hardness but different steel producers use different limits for its

specification. Generally, it is less than HRC 45, however, in technical literature and references the

steels with that hardness often relate to hard steel. The term and its hardness limit are allied

to cutting tool development and their ability to cut material. Therefore, steels can be divided

into the following conditional groups depending on their hardness:

Die and Mold Materials

Die and Mold

7

• Soft annealed to hardness up to HB 250

• Pre-hardened to two ranges:

- HRC 30-37

- HRC 38-44

• Hardened to two ranges:

- HRC 45-49

- HRC 50-55

- HRC 56-63 and more

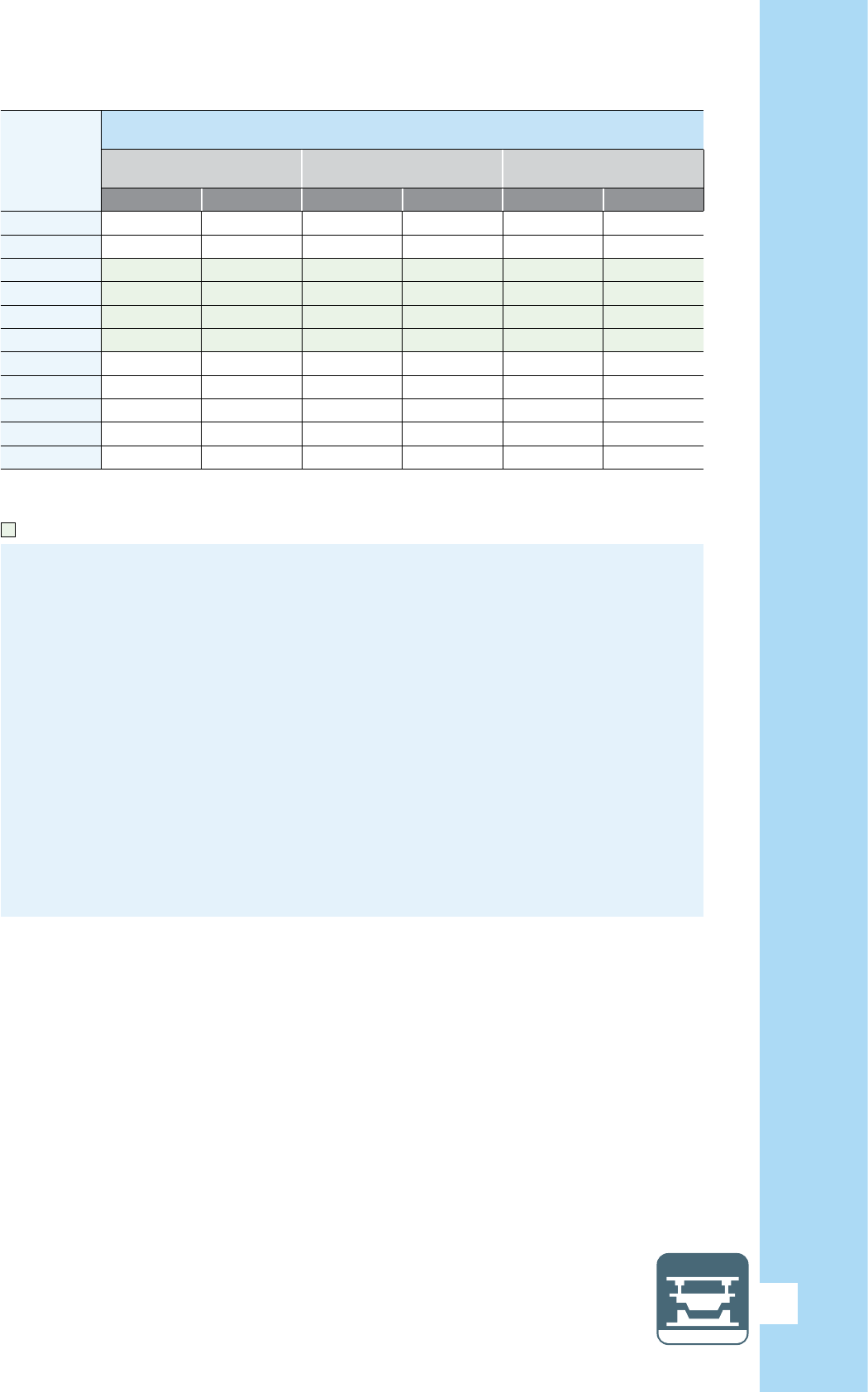

Table 1 shows some features of the most typical tool steels that are common in the

die and mold industry.

Not relating directly to tool steels, so called maraging steels (the term includes the words

martensitic

and

aging

) became be more and more usable in die and mold making, particularly, in

manufacturing plastic molds. They have relatively high Ni and Co percentage, can be supplied in

pre-hardened state (HRC 30-36, Maraging 250 and Maraging 300, for instance) and are hardened

to HRC 58. Nevertheless, despite their dimensional stability and good polishability, they are still

considerably expensive comparing with mold steels, and therefore their application in the die and

mold industry is limited.

Category

Designation Delivery

Hardening Application examples

AISI/SAE DIN W.-Nr. Annealed to Prehardened

Cold-work

tool steels

A2 1.2363 HB 220 HRC 56-60

Cold blanking, extrusion,

coining dies, molds

D2

1.2379

HB 210

HRC 56-62

Cold stamping and extrusion dies

and punches,

forging dies, master hobs

D3 1.2080 HB 240 HRC 56-62 Cold stamping dies and punches

O1 1.2510 HB 200 HRC 58-62

Forming dies and parts,

cold stamping dies

Hot-work

tool steels

H11 1.2343 HB 180 HRC 46-52 Hot extrusion dies, plastic molds

H13 1.2344 HB 190 HRC 44-54

Die-casting dies, punches,

plastic molds

Plastic mold

steels

P20 1.2330 HB 280 HRC 32-36 HRC 48-52 Plastic molds

Shock-resistant

steels

S7 HB 200 HRC 50-58

Hot forging dies, punches, master

hobs, cold extrusion dies

Special-

purpose steels

L6 1.2713 HB 230 HRC 36-44 HRC 50-60

Drop forging dies, die-casting dies,

plastic molds

Table 1 Typical Tool Steels for Die and Mold Making

Die and Mold Materials

8

Stainless Steels

Martensitic stainless steels (AISI 420, 420F) are widely used for producing plastic molds, especially,

for cavities of small to medium sizes with complicated shapes and substantial differences in cross-

sections. They are supplied as annealed to HB 200, and their heat treatment after machining is

simple.

Alloy Steels and Plain Carbon Steels

Alloy and even plain carbon steels are used for various general parts such as holders, pillars, pins,

rings, etc. Moreover, in many cases (low-run production dies, some kinds of molds) AISI/SAE

4130, 4140 and 4150 steels are main materials for forming parts. These three steels are usually

supplied in an annealed state or pre-hardened to HRC 32-35 and can be hardened to HRC 44-52.

The die and mold industry handles practically all types of engineering materials, but the most typical

for the branch are tool steels.

Cast Iron

Cast iron (especially grey) is also considered as a die and mold material for manufacturing large-

sized parts, plates, spacers, bushings and other components where wear is not expected. In

addition, nodular cast iron sometimes is used for dies, punches, jigs and pads and even for molds.

Nonferrous Metals

Aluminum is not the most popular material in the die and mold industry, but it often used for

prototype dies and molds, for multiplied identical molds, short life molds and various extrusion

molds because it is easy to machine and low cost. Today aluminum starts to penetrate into resin

mold manufacturing due to its much better thermal conductivity, machinability and polishability

compared to mold steels. The following aluminum alloys: 2024, 6061 and 7075 (in accordance

with the Aluminum Association Alloy and Temper Designation System) are more and more

common in mold making practice.

Beryllium-copper alloys and zinc alloy are materials for blow molds, injection mold components

and cavity inserts. Modern metal producers offer beryllium-copper alloys that have enough strength

and good wear and corrosion resistance properties. In machining, they are cut 2-3 times faster

than tool steels. The alloys’ hardness is HRC 30-42, depending on the hardness grade. For this

reason the beryllium-copper alloys can replace traditional tool steels and stainless steels as a mold

material in some cases.

Electrical discharge machining (EDM) is another important field of nonferrous metals application

in die and mold making. Electrodes for EDM are produced from brass, copper, copper tungsten

(60-70% of tungsten) and graphite.

Die and Mold Materials

Die and Mold

9

Machinability of Die and Mold Materials

The following data can be useful for estimating machinability of common die and mold materials in

regular delivery conditions. Machinability rating is based on AISI/SAE 1212 free cutting

steel as 100%.

¹ ASTM is the American Society for Testing and Materials

Carbon steels

1020 72% 1030 72% 1045 57%

1060 51% 1212 100% 1215 136%

Alloy steels

4130 72% 4140 66% 4340 57%

5015 78% 8620 68% 8720 68%

Tool steels

A2 42% D2 27% D3 28%

D7 25% H11 49 H12 46%

H13 46% H19 43% H21 36%

L6 39% O1 42% O6 57%

P2 42% P5 42% P20 38%

P21 38% S1 36% S5 31%

S7 45% W1 48% W2 45%

Martensitic stainless steels

403 55% 420 45% 430 45%

Grey cast iron (ASTM A48-76 classes¹)

20 (DIN GG 10) 73% 40 (DIN GG 25) 48%

Nodular cast iron (ASTM A 536-80 classes)

65-45-12 (DIN GGG 50) 61% 80-55-06 (DIN GGG 60) 39%

Aluminum alloys

6061-T 200% 7075-T 140%

Copper and copper alloys 80%-120%

Maraging 300 33%

Typical Examples of Dies and Molds

10

Typical Examples of Dies and Molds

Forging die

Die component……………....................

cavity

Material…………….………....................

S7

Hardness……………...............………...

HRC 52

Machining difficulty.................................

medium to high

Run size………………..............…….....

high-run production

Formed part……………….....................

connecting rod

Stamping die

Die component……………....................

punch

Material…………………….....................

D2

Hardness……………………..................

HRC 60

Difficulty for machining……...................

medium

Run size……………………...................

high-run production

Formed part……………….....................

hood

Die-casting die

Die component……………....................

cavity

Material…………………….....................

H21

Hardness……………………..................

HRC 51

Difficulty for machining……...................

low to medium

Run size……………………...................

medium-run production

Formed part……………….....................

tap's housing

Die-casting die

Die component……………....................

cavity

Material…………………….....................

H13

Hardness……………………..................

HRC 54

Difficulty for machining……...................

high

Run size……………………...................

high-run production

Formed part……………….....................

crankshaft

Plastic mold

Mold component…………....................

cavity

Material…………………….....................

H13

Hardness

HRC 50

Difficulty for machining……...................

low

Run size……………………...................

medium-run production

Formed part……………….....................

cellular phone housing

Plastic mold

Mold component…………….................

cavity

Material…………………….....................

P20

Hardness……………………..................

HRC 48

Difficulty for machining……...................

medium

Run size……………..............……….....

high-run production

Formed part……………….....................

car bumper

Die and Mold

11

Cutting Tools in

Die and Mold Industry

In die and mold manufacturing, there are different machining operations: cutting (milling, drilling,

reaming, etc.), abrasive machining (grinding, polishing, honing, etc.) and EDM. Even water jet

cutting is used by die and mold makers. However, metal cutting remains to be the predominant

method of die and mold production.

Dies and molds have different shapes and sizes, varying from small to large. In many cases

machining dies and molds requires removing a large amount of material. A typical machining

process contains rough and finish cutting operations. The main parameter for rough machining

with a large stock allowance is metal removal rate, while for finishing, the most important factors

are accuracy and surface finish.

For the development of machine tools, CNC control and CAD/CAM systems cardinally changed

the die and mold industry by giving the die and mold maker new methods of multi-axis machining

and introducing advanced computer techniques of machining simulation and verification. Modern

cutting strategies, such as high speed machining (HSM), high feed milling (HFM) and trochoidal

milling have penetrated into die and mold production. Machining hard materials, long tool life,

stability, reliability and high performance intended for reducing or even full elimination EDM and

manual polishing – only the tool that meets these requirements can be considered a passport to

success in productive and effective die and mold making.

Milling Tools

12

Milling Tools

Milling plays a key role in machining dies and molds. Indeed, milling tools remove the most

share of material, shaping a workpiece to a die or mold part. A conventional process planning

comprises rough, semi-finish and finish milling operations. The traditional approach to rough milling

is based on cutting with large depth and width of cut. Correspondingly, it demands high-power

machine tools with low spindle speeds for large milling tools. This way of machining provides

maximum productivity when cutting a soft material. Due to a die or mold has appropriate hardness

requirements and in addition, heavy-duty rough milling leads to significant residual stresses,

further heat treatment is necessary. The mentioned approach usually characterizes production of

large-sized die and mold parts that have considerable differences in depth or height. However,

some producers are still supporters of this method due to limitations of available machine tools,

CNC programs or traditional thinking in process planning. Over time, and as industrial innovations

developed, HFM became a relevant technique in roughing. It allows machining soft to pre-

hardened steels with small depth of cut and extremely high feed per tooth and leads to increased

productivity.

HSM, another modern way of metal cutting, is intended first of all for finish milling of hard steels.

Nevertheless, it can be effective also for rough and semi-finish machining, particularly for small to

medium parts or in cases with slight differences in depth or height because it enables cutting hard

material directly. Further HSM development has resulted in trochoidal milling.

Yet one method of rough milling growing in popularity in the die and mold industry is plunge milling

(or plunging) with a tool feed direction towards the tool axis. It gives the opportunity for efficient

roughing of cavities and external surfaces with a complex shape (so called sculpturing operations).

The modern milling techniques, their advantages and problematic points and requirements of

cutting tools will be discussed on the following pages of the guide.

All typical milling operations are involved in die and mold manufacturing: 90˚ shoulder milling,

face milling, milling slots, contours and chamfers; and profile milling (the parallel definition of the

operations: shouldering, facing, slotting, countering, chamfering and profiling, also are often used

by professionals). The latter, including machining shaped 3D surfaces, is the pivot of die and mold

making. Milling tools are available in different configurations: indexable, that has replaceable cutting

inserts or whole cutting heads, and solid.

Milling Tools

Die and Mold

13

Selection Guideline: How to Choose the Right Milling Tool

Putting the question of tool selection into broad perspective, the main side of the issue shall be

emphasized: cost per unit (CPU) for a part that is machined by the tool. In spite of the fact that

the tooling cost share in CPU is minor, the tool’s indirect influence on CPU reduction can be

considerable. Namely the tool, this small part of a manufacturing process, sometimes is a single

obstacle for a machine tool to run faster and thus to cut machining time.

Hence, for better productivity and as a result for lower CPU the most high-efficiency tool

should be used.

Another important aspect is versatility of the cutting tool, its ability to perform various milling

operations effectively. For example: shoulder milling, ramping and plunge milling. Such combinations

allow for using one tool for different applications and, when machining a part, shortening time

needed for tool change during machining.

An additional way of increasing versatility is using the tools with interchangeable precise cutting

heads, which render a possible head change when the tool or its holder is clamped into a machine

spindle and does not require time for setup procedures.

Taking these so obvious, but often left out points into consideration and speaking about the tool

selection more specifically, the analysis by chain: Application-Geometry-Grade (AGG) shall be

applied. In brief, AGG means the following commonly known checkpoints - questions, answer on

which allows for the tool choice:

Application What is the type of machining operation?

Workpiece: its material, hardness before the operation

Required accuracy and surface finish

Machining allowance

Machining strategy

Type of machining (light, medium, heavy)

What type of tool, in accordance to adaptation (a mill with shank, shell mill)?

Operation stability (good, bad)

Machine tool (sufficient/limited power, condition, spindle speed)

Coolant (coolant type: dry, wet; possibility of coolant throw spindle)

Geometry Which cutting geometry is recommended for machining the workpiece

for the above requirements? Both types of tools should be checked:

indexable and solid.

Grade Which grade of a cutting tool material is more suitable for machining the

workpiece for the above requirements?

Carbide Grades for Indexable Milling Inserts

The indexable inserts for milling the die and mold materials are produced from different tungsten

carbide grades, mostly coated by methods of physical or chemical vapor deposition (PVD and

CVD respectively).

PVD coatings have a wide distribution in milling inserts and solid carbide endmills because they

leave the cutting edges sharp. PVD coatings are applied at relatively low temperature

(about 500 ˚C).

CVD coatings are much thicker and that contributes to wear resistance. The CVD coatings are

applied at high temperature (approximately 1000 ˚C). Current technology enables improving CVD

process by moderate-temperature CVD (MT CVD) with its lower deposition temperatures. Further

steps in technology development include combinations of both coating methods: CVD and PVD.

ISCAR offers a rich program of the carbide grades for the milling inserts. We observe briefly the

more recent of them intended primarily for machining the popular die and mold materials. Except

for grade DT7150, the preferred grades, which are produced by SUMO TEC method, have

Milling Tools

14

ISO Class

DIN/ISO 513

Carbide Grades

IC808 IC5100 IC810 DT7150 IC830 IC330

P

P15-P30 P10-P25 P15-P30 P20-P50 P25-P50

M

M20-M30 M20-M40 M30-M40

K

K20-K40 K05-K20 K05-K25 K05-K25 K15-K40

H

H20-H30

Coating PVD MT CVD PVD Combination PVD PVD

Table 2 Selected Carbide Grades for Indexable Inserts Intended

for Milling Die and Mold Materials

For more detailed information about the carbide grades and coating technology refer to ISCAR

catalogs, guides and technical leaflets.

- First choice

Ferritic and martensitic s.s. (ISCAR material groups 12;13)

Tougher

Harder

a special post-coating treatment with extra advantages. Table 2 contains the comparative data for

general characteristics of the grades.

IC808 is a grade with tough submicron substrate and titanium aluminum nitride (TiAlN) PVD

coating, designed for milling die and mold materials such as hard alloy and carbon steels at

medium-to-high cutting speed. They are noted for excellent notch wear and built-up edge

resistance.

IC5100 – a tough substrate with a MT CVD and alpha aluminum oxide (Al

2

O

3

) coating that is

recommended for milling grey cast iron at high cutting speeds, providing excellent tool life.

IC810 – a PVD grade coated with aluminum titanium nitride (AlTiN) that produces high oxidation

resistance, enabling machining at high speed. A good choice for miling nodular and grey cast iron

at low to medium cutting speed under unstable conditions.

DT7150 – a carbide grade with a tough substrate that has a dual MT CVD and TiAlN PVD coating.

Features high wear and chipping resistance. Recommended for medium to high cutting speeds for

machining of cast iron and cast steel, especially with siliceous skin.

IC830 – a PVD TiAlN coated tough grade for milling alloy steel and stainless steel. Shows good

results for interrupted cut and heavy duty operations.

IC330 – a multi-purpose tough grade with titanium nitride (TiN)/titanium carbonitride (TiCN)

coating. Used for milling a wide range of die and mold materials, at low to medium

cutting speed.

SUMO TEC carbide grades

The SUMO TEC grades feature a special post-coating treatment which provides substantially

improved life and better reliability. The new process enhances toughness and chipping resistance,

reduces friction and built-up edge, thus increasing tool life. The golden-colored flank facilitates

wear detection. The post-coating treatment has the effect of making the rake face even and uniform,

minimizing inner stresses and droplets in coating, which lead to smooth chip flow and extended

tool life. Yet at the same time the untreated flank continues to be rough enough for good contact

with base surfaces of tool pockets.

Milling Tools

Die and Mold

15

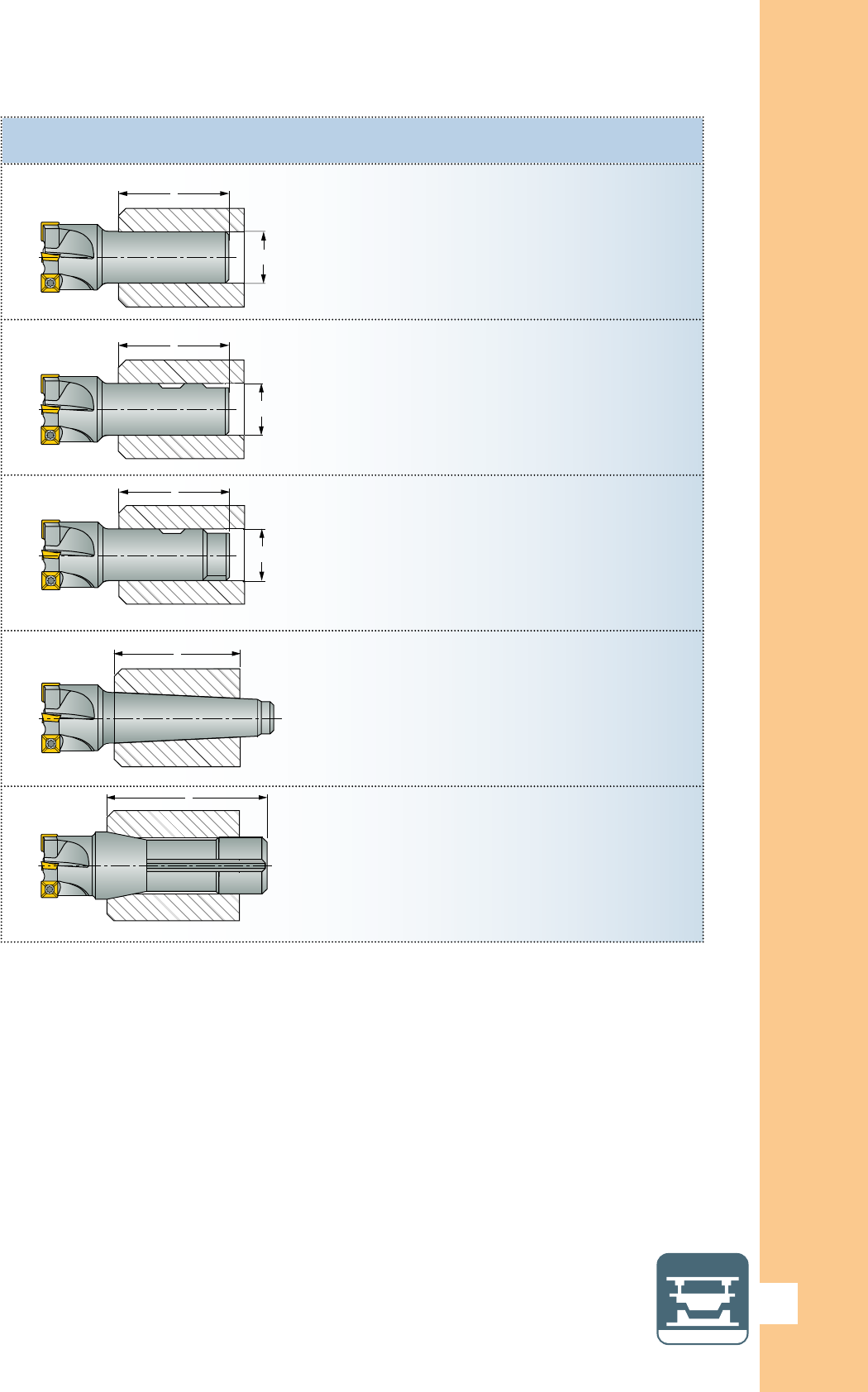

90˚ Shoulder Milling

ISCAR endmills that are intended mostly for 90˚ (square) shoulder milling but used also for

milling slots and grooves, are being developed in the following directions:

• Endmills with indexable inserts of diameter range 8-50 mm

• Solid carbide endmills with diameters to 25 mm

• Replaceable milling heads with MULTI-MASTER adaptation (or simply MULTI-MASTER heads)

of 6-25 mm diameters

• Extended flute endmill cutters of diameter range 12-100 mm

The extended flute endmill cutters are for roughing, while the other kinds of

endmills are used in all kinds of operations: roughing, semi-finishing and finishing.

Insert with helical cutting edge

In the 1990’s ISCAR introduced new milling cutters which carried indexable sintered carbide

inserts APKT 1003 PDR-HM. It was the first insert with a helical cutting edge. Now an insert cutting

edge as a part of a helix that is built on a cutting cylinder seems apparent, and many tool

manufacturers use this approach for producing their milling inserts.

But in the 1990’s it was a real innovative solution. A helical edge ensured constant cutting geometry,

smooth cutting and considerably improved insert life. Ground HSS and solid carbide tools,

which were known long before, already had helical edges; however, the edge was made

by grinding. Nonetheless, producing a replaceable carbide insert with a helical edge by means of

pressing technology only was a serious problem at that time, and its solution by ISCAR brought

about revolutionary changes in the cutting tools industry.

HELIMILL – a line of new milling tools was born.

Endmills with Indexable Inserts

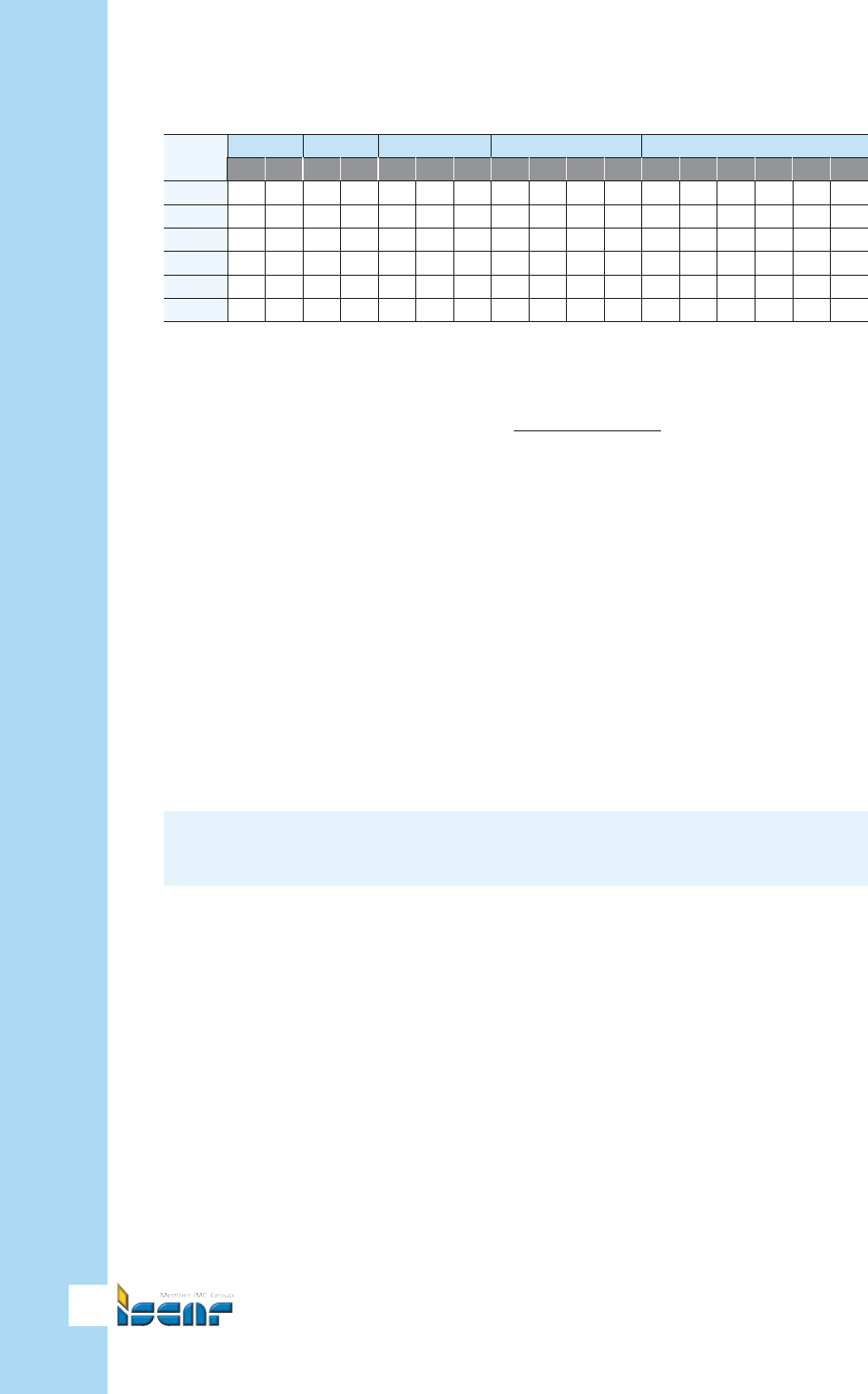

The main functional features of the most popular ISCAR endmills with indexable inserts are

summarized in Tables 3 and 4. Table 3 shows the number of teeth of the tools as a function of the

tool diameter and its maximal depth of cut; and Table 4 is intended for estimating the rampdown

ability of the tools.

Machining cavities is a typical feature of die and mold making. Hence, the ability to drill with

subsequent milling is an important attribute of a milling tool. Another significant factor is a tool

capability to ramp milling when the tool is simultaneously fed in radial and axial directions.

If the tool moves axially upward, it is ramp up milling (ramping up); and if it moves axially

down – ramp down milling. Maximal rampdown angle characterizing tool possibilities in ramping

is a valued feature for tool selection. The angle depends on cutting geometry and the nominal

diameter of a tool. For tools with high overhang from a toolholder (long and extra long series

of the tool overall length) the rampdown angle should be additionally diminished.

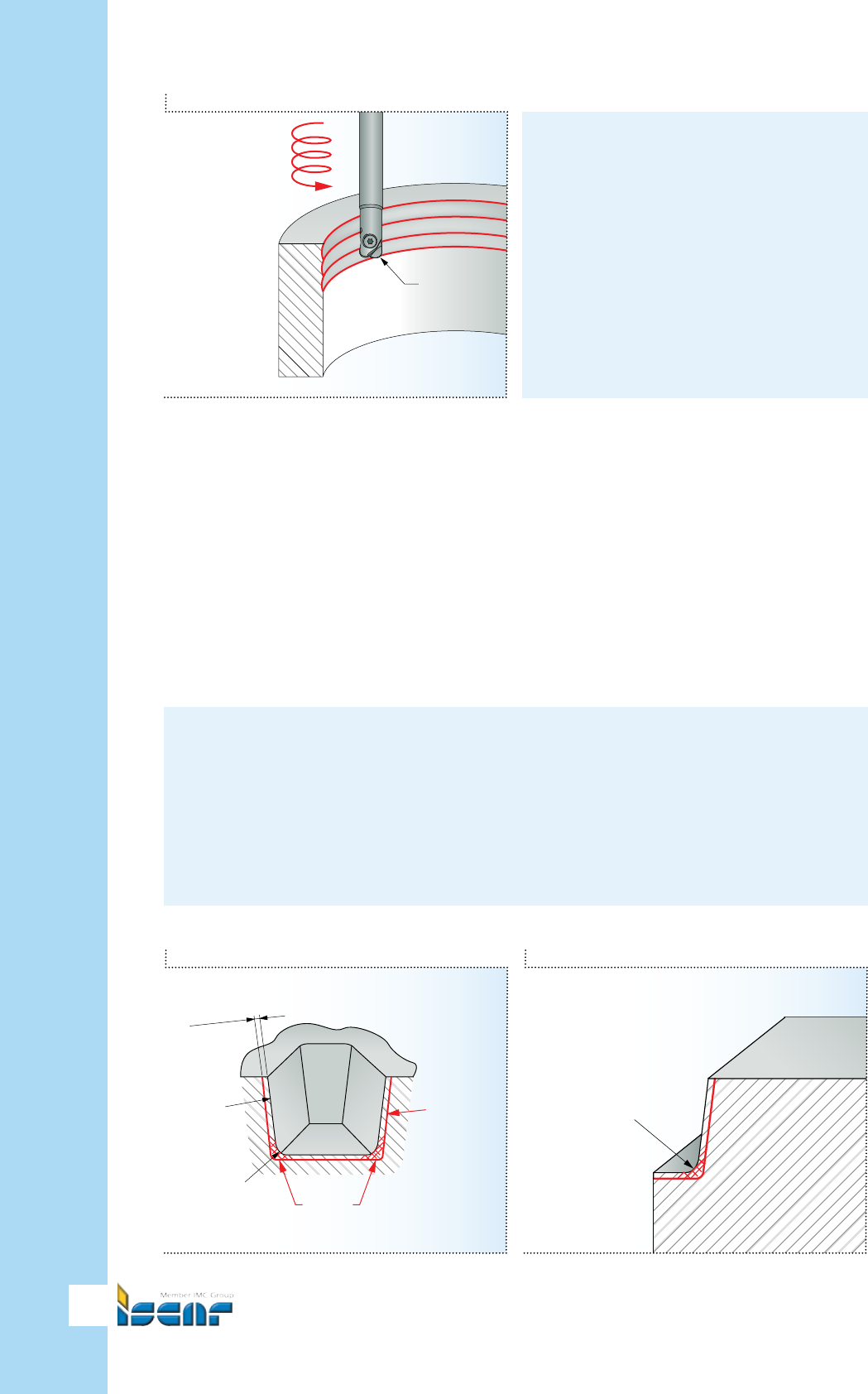

Three axes milling by helical interpolation is a widely used method for machining holes especially

with a large diameter. A cutter, which travels simultaneously along three coordinate axes of

a machine tool, moves planetary about an internal hole diameter and creates the summarized

cutting helical movement.

The helix angle is dependent of the maximal rampdown angle of the tool performed interpolation.

The helical tool path maintains smooth entry in the material and uniform loading of the tool.

The particular case of helical interpolation is two axes milling by circular interpolation when only

the planetary movement is made.

The depth of a machined hole depends on the maximal allowed depth of cut of the tool.

Chip evacuation and chip re-cutting are factors that affect a milling tool machined

cavities by a different technique.

1

Milling Tools

16

T290 ELN -05 HP E90AN

T490 ELN -08

T490 E90LN -08 H490 E90AX -09 HM90 E90A T290 ELN -10

ap 5 7.7 8 8 10 10

Tool D Number of Teeth (Effective)

8 1

10 2 1 1

12 2; 3 2 1

14 3 1

16 4; 5 3; 4 2 2 2

17 2

18 2

20 4; 5 2; 3 3 2; 3 2; 3

21 3

22 3

25 5; 7 3; 4 4 2; 3; 4 3; 4

28 4

30 4

32 6; 8 3; 5 5 3; 4; 5 4; 5

40 8; 10 4; 6 3; 5; 6 6

50 7

Inserts T290 LNMT 05 HP ANKT T490 LN..T 08 H490 ANKX 09

HM90 AP…10

AP…10 T290 LNMT 10

Table 3 Quick Selector for 90˚ Indexable Endmills

Table 3 Quick Selector for 90˚ Indexable Endmills (cont.)

H490 E90AX -12 T490 ELN -13 HM90 E90AD T490 ELN -16 H490 E90AX -17

ap 12 12.5 14.3 16 16

Tool D Number of Teeth (Effective)

8

10

12

14

16

17

18

20 1

21

22

25 2 2

28

30

32 3 3 2; 3 2 2

40 4 3; 4 2; 3; 4 3 3

50 5 4; 5 5 4 4

Inserts H490 AN..X 12 T490 LN..T 13

HM90 AD..15

AD..15 T490 LN..T 16 H490 AN..X 17

Milling Tools

Die and Mold

17

Table 4 Rampdown Angle for 90˚ Indexable Endmills

Table 4 Rampdown Angle for 90˚ Indexable Endmills (cont.)

*

Lower values for tools with long overall length

**

Valid only when H490 ANKX 1706R15T-FF is used.

T290 ELN -05 HP E90AN

T490 ELN -08

T490 E90LN -08 H490 E90AX -09 HM90 E90A T290 ELN -10

ap 5 7.7 8 8 10 10

Tool D Rampdown angle, ˚

8 2.5

10 2.3 2.5 5

12 2 2.7 32

14 1.5 Ramp Ramp 7

16 1 3.2 15

17 down down 15/4.5*

18 7.5

20 2.4 prohibited prohibited 7.5 4

21 7.5/2.8*

22 7.5

25 2 5 2.2

28 2

30 2

32 1.4 3 1.6

40 1 2.7 1.2

50 2.7

Inserts T290 LNMT 05 HP ANKT T490 LN..T 08 H490 ANKX 09

HM90 AP…10

AP…10 T290 LNMT 10

H490 E90AX -12 T490 ELN -13 HM90 E90AD T490 ELN -16 H490 E90AX -17

ap 12 12.5 14.3 16 16

Tool D Rampdown angle, ˚

8

10

12

14 Ramp Ramp Ramp

16

17 down down down

18

20 prohibited prohibited 3 prohibited

21

22

25 11.5

28

30

32 5. 3 6.5**

40 4 4.4**

50 5 3.8**

Inserts H490 AN..X 12 T490 LN..T 13

HM90 AD..15

AD..15 T490 LN..T 16 H490 AN..X 17

Milling Tools

18

General Characteristics of the Latest ISCAR Lines of

Indexable Tools for 90˚ Milling

No mismatch

In machining square shoulders by indexable milling tools, the shoulder height can be more than

a tool depth of cut (D.O.C.) that is determined by the length of cutting edge of an insert clamped in

the tool. In this case the shoulder machining needs two or more continuous passes. Ensuring true

90˚ shoulder profile without a detectible border, steps, marks or burrs between the passes –

no mismatch – is an essential feature of modern precise indexable milling tools intended for milling

square shoulders.

Use of such tools substantially improves productivity by eliminating additional finish cuts and ensures

the high-accuracy profile with good surface finish. Perpendicularity of the shoulder wall to its base of

no more than 0.02 mm is today a normal requirement to the “no mismatch” milling tools.

HELITANG T490 is a family of milling tools that uses tangentially clamped inserts with four right-

hand helical cutting edges. The T490 inserts are available in 8, 12.5 and 16 mm long cutting

edges. The smallest tool diameter is 16 mm, with 2 teeth. The line offers the tools in different

configuration: end and face mills, replaceable milling heads for ISCAR MULTI-MASTER and

FLEXFIT systems; and the tools are available with coarse or fine pitch. Most of the tools are

provided with holes for internal coolant supply. The tools are intended for milling square shoulders

at high rates, with no mismatch and they are capable of plunging as well.

The family features high durability and outstanding tool life, due to the tangentially oriented pocket,

the most advanced insert production technology and excellent grade combination.

It is interesting to note that none of ISCAR competitors can offer such a small tangential insert as

the T490 LN.. 0804PN-R with four cutting edges.

HELIDO H490, a family of tools for 90˚ milling, is an evolution of the original ISCAR HELIMILL line.

The H490 AN.. X laydown (radial) insert has 4 right-hand cutting edges. There are 3 standard sizes

of the insert with cutting edge lengths 8, 12 and 16 mm.

Insert construction is very thick and strong. It is clamped into a dovetail inclined pocket, which

provides a very rigid clamping, and has a wiper that leaves an excellent surface finish. Due to its

strong construction, unique chip deflector with positive rake angles and good grade combinations,

the family stands out high durability, low cutting forces and long tool life. The tools, which are

produced with coolant holes, can machine 90˚ shoulders with no mismatch, plunge with large

stepover and can perform milling slots and faces.

This family combines the most advantageous features of both the HELIMILL – helical cutting edge

and positive rake angles; and the MILL2000 – strong construction, most suited for heavy milling

applications.

3P ISCAR Premium Productivity Products

Since 2007 this symbol started coming into view on packages of various ISCAR products and on

pages of leaflets. The symbol stands for new tools, inserts and toolholders, which are

manufactured in accordance with the advanced designed principles and the latest technology,

and allow to the customer substantial productivity increase.

In addition to the progressive cutting geometry, the key features of the 3P cutting inserts are the new

SUMO TEC carbide grades with their special post-coating treatment.

Milling Tools

Die and Mold

19

SUMOMILL T290 is a family of milling tools with coolant holes that uses tangentially clamped

inserts with two cutting edges. The T290 inserts are available in 5 and 10 mm long cutting

edges. The inserts are the next evolution of the most popular HELIMILL inserts. As a result of

their tangential orientation in the pocket, the inserts allow tool design with larger core diameter,

providing a much stronger tool construction, which sustains a higher impact load and reduces the

risk of fracture to a minimum. When compared to the current HELIMILL and HELIPLUS tools of

similar sizes, the tools of the line feature high long-term strength and remarkable tool life, due to

the tangential orientation of the inserts in the pockets and higher tooth density.

The tools runs at higher feed speeds (table feeds), producing excellent surface finish and no

mismatch; and are suitable for plunging and rampdown applications. Their increased radial and

axial rake angles lead to a major reduction in cutting forces, improve tool stability and prolong life of

the cutting edge.

The T290 unique convex shaped insert enabled the development of small diameter cutting tools of

even 8 mm diameter.

Tangential or radial?

The question: what is more effective – tangential or radial clamping, often can lead the

user to hesitate when selecting the right cutting tool when there are both milling cutters with

laydown (radial) inserts and with inserts clamped tangentially. As in many practical cases,

the question has no strictly unambiguous answer. The academic studies of the question are

beyond the scope of the guide. Therefore, a brief review of advantages and disadvantages of each

clamping principle can be useful for the right choice. In general, the tangential configuration allows

increasing feed per tooth because the tangential component of a cutting force acts against an

insert with more rational orientation of its cross-section.

The well-designed tangential insert contributes to optimal loading of a clamping screw while

the resultant cutting force is transmitted directly to the cutter body. The tangential clamping

enables cutter design with larger core diameter than tools with radial inserts. It is much easier

to provide an indexable double-sided insert with helical cutting edges if a tangential configuration

is applied. And finally, the tangential clamping configuration also offers a higher insert density.

Typically, the milling cutters with tangentially clamped inserts run at high feed rates especially

when machining cast iron.

However, relative to milling tools with the laydown (radial) inserts, the cutters with the tangential

clamping normally have lesser ramping abilities, and their resources for shaping rake face and high

positive axial rake, which can significantly reduce cutting forces, are limited. Greater chip gullets in

case of the radial inserts go a long way towards better chip evacuation when milling materials such

as steel with high metal removal rate, particularly in machining deep cavities.

The latest ISCAR design provides the customers with the milling tools with tangential and radial

inserts for which in many cases the disadvantages related to tangential and radial clamping

correspondingly were overcome. For example, the H490 line with double-sided radial H490 AN…X

inserts, real workhorses, are intended for heavy milling operations with high feed per tooth;

and T290 line that is based on tangential T290 LN…T inserts is notable by excellent rampdown

performance. In either event the question of using the cutters with tangentially or radially clamping

inserts should be solved specifically. The ISCAR application specialists will be glad to advise

you the best choice.

Milling Tools

20

How to Start: Cutting Data

General Principles

Cutting speed Vc and feed per tooth fz, the first key parameters in milling, depend on

different factors.

Before everything else, a carbide grade. The harder grade has higher wear resistance and enables

higher cutting speed. The tougher grade with its better impact strength is intended for the

lesser speed, but allows greater feed per tooth.

Machinability of engineering materials is different, and even the same material can be substantially

different by its machinability (for example, milling a tool steel in different conditions: annealed,

pre-hardened and hardened). Therefore, a specific force needed for removal of a unit of a chip

section, and load acting on an insert differ too. It is evident; the machinability factor should be

taken into consideration.

Insert geometry is also important. A sharp cutting edge, which is brittle and can not stand up

against a serious load, sets the upper limit to the feed. The T-land, a negative land protecting

the cutting edge, conversely, binds the feed below because too small a feed causes in this case,

considerably increased cutting force.

Another factor - the milling tool body. A durable design of the body and a reliable method of

securing the insert ensure machining under high cutting data.

Further, the application. What is the aim of tool use? In rough milling, when a relatively large

volume of material is removed, the feed is high and the cutting speed is moderate. At the same

time, finish milling operations performing with small allowances demands maximal speeds and

small to medium feeds for high machining accuracy and good surface finish. Different limitations

such as large overhang (in milling deep cavities, for example), improper clamping, workpiece with

a thin wall and others lead to decreasing the speed, the feed or even both.

Lastly, the machine tool and toolholding. Poor machine conditions and not rigid toolholders create

an additional barrier for increased cutting data.

The mentioned arguments are very general; and no doubt everyone who is involved in metal cutting

is familiar with them. They are a good illustration of complex dependence or the cutting data on

different attributes. How to go from the generalities to the particulars and specify the

starting cutting data?

We can take into account the application factor and the machine tool conditions by introducing

operation estimation: light, medium and heavy. Then we can prepare the tables with the

recommended cutting speed and feed for every milling line and thus provide the user with the

cutting data. It is a correct approach; and the cutting data recommendations in full application

guides, tool advice software and specific guidelines use it in full.

In the U.S.A., instead of the term “feed per tooth” (“fpt”), “chip load” is often used; “advance per

revolution” means “feed per revolution” (“fpr” or “feed”) and “advance per minute” or “feed rate”

– “feed speed” (“feed per minute”, “fpm”, or “table feed”).

Milling Tools

Die and Mold

21

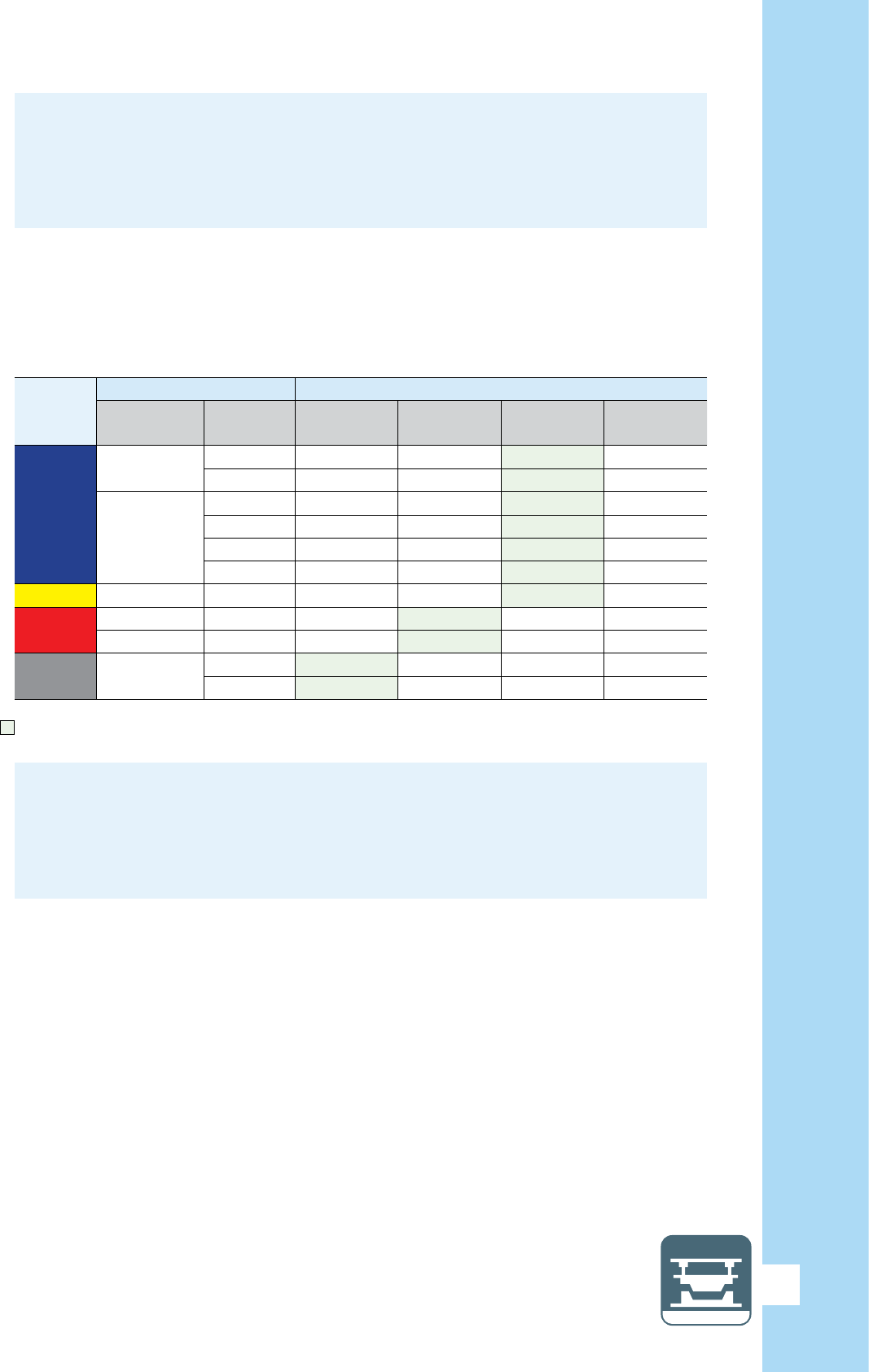

Starting Feed

Table 5 contains data for estimating starting feed per tooth. Smaller values more suitable for

finish operations and greater feeds usually characterize rough milling. In case of high tool overhang

and unstable technological system (poor clamping, cutting thin wall workpieces and so on),

the feed should be reduced by 20-30%.

Starting Speed

Vc = Vo x Ks x Kt (1)

Where: Vc – starting cutting speed

Vo – basic cutting speed

Ks – stability factor

Kt – tool life factor

a) Basic cutting speed Vo

Table 9 determines the basic cutting speed depending on carbide grade, workpiece

material and type of machining. The basic cutting speed relates to a 20 minute tool-life period.

In order to define what is known as light duty, moderate duty and heavy duty machining

more rigorous, we introduce the following two-step procedure.

Tooth Loading

In shoulder milling, tooth loading is a function of the ratios:

• Cutting depth h to a length of cutting edge a

p

• Width of cut b to the nominal diameter of a milling tool D

The tooth loading reflects a fraction of the cutting edge involved in cutting and a cycling path

of the tooth in the workpiece material from the tooth entering to the tooth exit.

While remaining in the material too long, the tooth experiences more intensive heat loads that

affect the tool life.

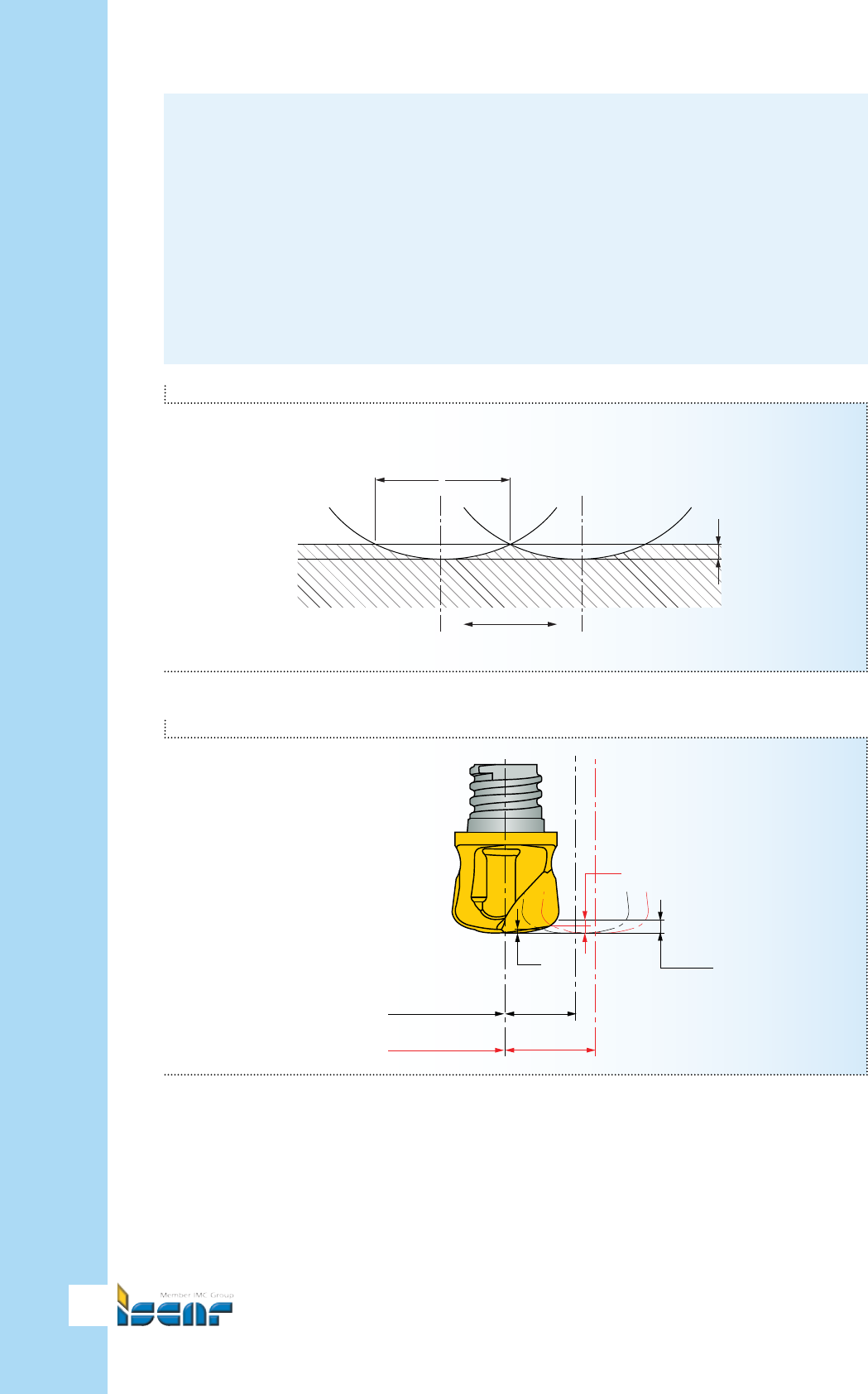

The diagram shown in Fig. 1 allows defining the tooth load, but for a quick rough

estimate, Table 6 may be enough.

Type of Machining

The tooth load in combination with the feed per tooth defines the type of machining (Table 7).

The feed interval from fz min to fz max relate to a field of the estimated starting feeds as above.

Do not take literally “minimum”, “maximum” and “moderate” feeds: the feeds

closed to the lower border of the field relate to fz min, the average values – to fz moderate,

and the feeds closed to the upper border – to fz max.

Milling Tools

22

ISO Class

DIN/ISO 513

Workpiece material Starting feed fz, mm/tooth, for grades

Type

Mat.

Group*

σ

T

N/

mm

2

Hard-

ness,

HB

IC808 IC5100 IC810 DT7150 IC830 IC330

P

Plain carbon

steel

1-4 <850 <250 0.1-0.25 0.1-0.25 0.1-0.25 0.1-0.35 0.1-0.4

5

>850

<1000

>250

<300

0.1-0.25 0.1-0.25 0.1-0.25 0.1-0.3 0.1-0.4

Alloy steel

and

tool steel

6, 7 <1000 <300 0.1-0.25 0.1-0.2 0.1-0.25 0.1-0.3 0.1-0.4

8, 9

>1000

<1200

>300

<350

0.1-0.2 0.1-0.18 0.1-0.2 0.1-0.25 0.1-0.3

10 <850 <250 0.08-0.18 0.08-0.15 0.08-0.18 0.1-0.25 0.1-0.25

11

>1100

<1450

>325 0.08-0.15 0.08-0.12 0.08-0.15 0.08-0.2 0.08-0.25

M

Martensitic

s.s.

12, 13 <850 <250 0.08-0.12 0.08-0.15 0.08-0.2

K

Grey cast iron 15-16 <1000 <300 0.2-0.35 0.2-0.4 0.2-0.4 0.2-0.3

Nodular cast

iron

17-18 <1000 <300 0.2-0.35 0.2-0.4 0.2-0.4 0.2-0.3

H

Hardened

steel

38.1

>1480

<1700

HRC

45-49

0.07-0.12 0.07-0.1

38.2

>1700

<2000

HRC

50-55

0.06-0.09

39

>2000

<2500

HRC

56-63

0.05-0.08

Table 5 Estimated Starting Feed fz

*

ISCAR material group in accordance with VDI 3323 standard

- First choice for grades

For T290 milling tools the table values should be reduced by 30%.

For the face mills with inserts HP ANKX…07 and T490 LN..T…08 the table values should be reduced by 20%.

For milling hardened steel, see the appropriate chapter for further discussion.

Harder

Tougher

h

a

p

3

4

3

4

1

2

1

2

1

4

1

4

1

1

b

D

Heavy

Moderate

Light

h

a

p

3

4

1

2

1

4

1

4

1

1

Heavy

Moderate

Light

1

2

3

4

b

D

b

h

a

p

D

Fig. 1. Tooth load areas

Milling Tools

Die and Mold

23

b/D

h/ap

1/4 1/2 3/4 1

1/4 light moderate moderate moderate

1/2 moderate moderate moderate heavy

3/4 moderate heavy heavy heavy

1 moderate heavy heavy heavy

Table 6 Tooth Load

Tooth loading

Type of Machining for Feed per Tooth fz

fz min fz moderate fz max

Light tooth loading Light-duty (L) Light-duty (L) Medium-duty (M)

Moderate tooth loading Light-duty (L) Medium-duty (M) Heavy-duty (H)

Heavy tooth loading Medium-duty (M) Heavy-duty (H) Heavy-duty (H)

Table 7 Type of Machining

b) Stability Factor Ks

The factor is defined by the below estimate of milling operation stability:

• for normal stability Ks = 1,

• for unstable operations (high overhang, poor clamping, milling thin walls, etc.)

Ks = 0.7

c) Tool Life Factor Kt

The factor that relies on the relationship cutting speed-tool life is shown in Table 8

Table 8 Tool life factor Kt

Tool life, min. 10 20 40 60

Kt 1.15 1 0.85 0.8

Example

The workpiece from AISI P20 steel with hardness HRC 32 is machined by ISCAR indexable endmill

cutter H490 E90AX D25-4-C25-09. The cutter carries inserts H490 ANKX 090408PNTR IC830.

The application – rough to semi-finish milling of a square shoulder with 4 mm depth and 16 mm

width. The workpiece is properly clamped; and the stiffness of the whole technological system

(machine tool + fixture) is estimated as sufficient.

The machined material relates to the ninth material group (No.9).

In accordance with Table 5 starting feed fz =0.2 mm/tooth (the value that is close to

the upper border).

The length of the cutting edge for the insert above is 8 mm (from the catalog or Table 3).

Hence, h/ap=4/8=0.5 and b/D=16/25≈0.6.

From Table 6 the tooth load is moderate; and from Table 7 the type of machining takes "medium-

duty" definition. Ks is accepted as 1 (paragraph b).

Therefore, as per Table 9 starting cutting speed for 20 min. tool life Vc=135 m/min.

For 60 minute tool life, tool life factor Kt=0.8 (Table 8); and the starting cutting speed in this case

will be 108 m/min.

Milling Tools

24

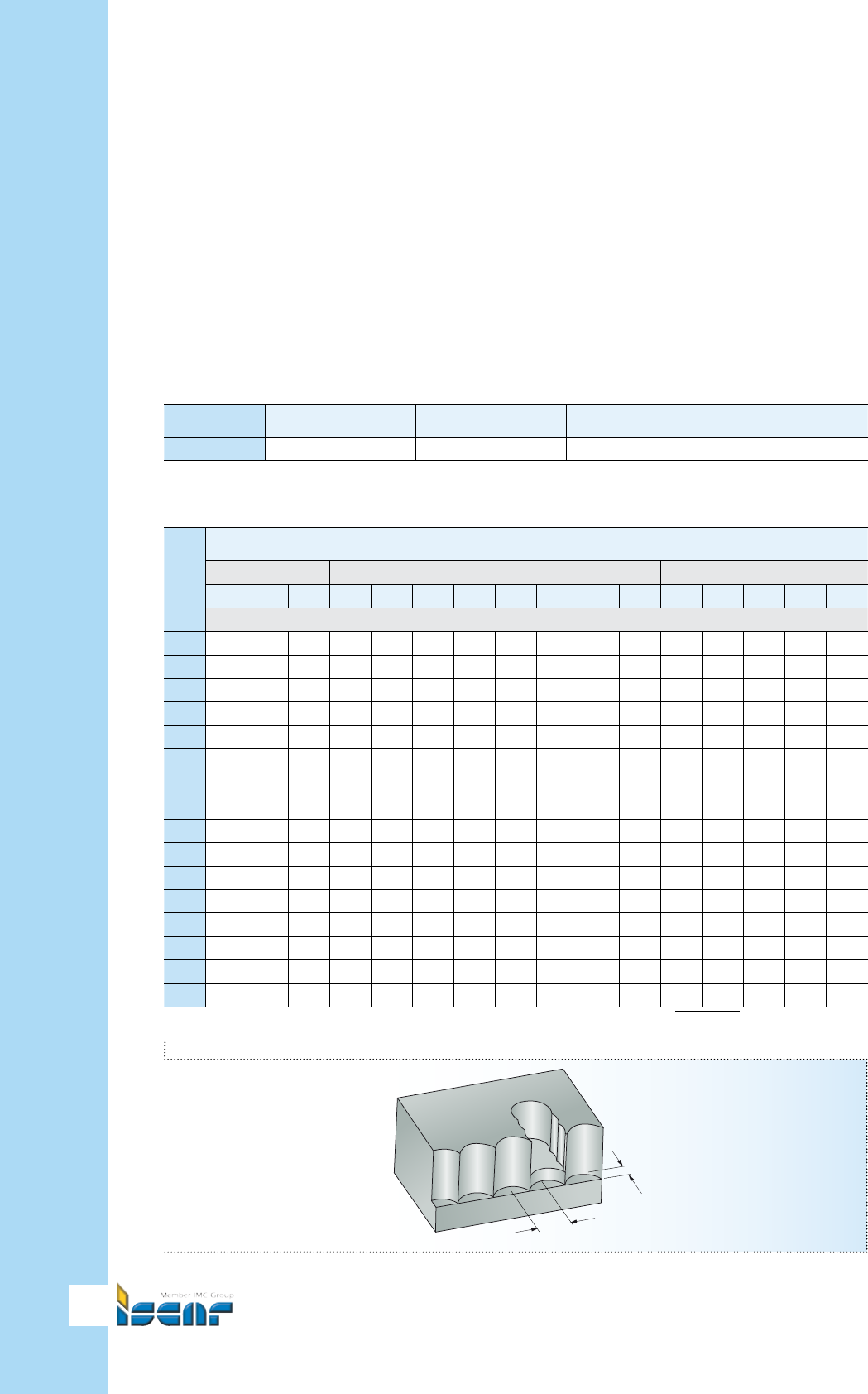

Table 9 Basic Speed Vo for Selected Grades in Relation to Type of Machining*

ISO Class

DIN/ISO 513

Workpiece Material Basic speed Vo, m/min, for grades and type of machining

Type

Material

group**

σ

T

, N/

mm

2

Hardness

HB

IC808 IC5100 IC810 DT7150 IC830 IC330

L M H L M H L M H L M H L M H L M H

P

Plain

carbon

steel

1 <850 <250 300 240 220 260 230 200 200 170 150 185 160 135

2-4 <850 <250 280 220 200 240 200 180 180 150 135 170 140 125

5 >850 <1000 >250 <300 240 200 180 215 190 170 150 135 120 135 120 115

Alloy steel

and

tool steel

6, 7 <1000 <300 230 200 170 200 180 160 170 140 125 150 135 120

8, 9 >1000 <1200 >300 <350 215 185 165 180 150 125 150 135 120 140 125 115

10 <850 <250 210 190 170 165 135 110 140 125 115 130 120 110

11 >1100 <1450 >325 165 135 115 150 125 105 135 120 115 125 110 100

M

Martensitic s.s. 12, 13 <850 <250 200 170 140 170 140 125 150 130 120

K

Grey cast iron 15-16 <1000 <300 260 220 200 300 250 220 300 250 220 300 250 220 260 220 190

Nodular cast iron 17-18 <1000 <300 240 200 180 250 220 200 250 220 200 250 220 200 200 185 160

H

Hardened steel***

38.1 >1480 <1700 HRC 45-49 120 100 80 100 80 70

38.2 >1700 <2000 HRC 50-55 75 55

39 >2000 <2500 HRC 56-63 65 45

*

For 20 min. tool life.

**

ISCAR material group in accordance with VDI 3323 standard

***

Milling hardened steel see under the appropriate chapter for further discussion.

- First choice for grades

Milling Tools

Die and Mold

25

Solid Carbide Endmills

ISCAR offers the die and mold makers a rich line of solid carbide endmills with 90˚ lead angle for

machining square shoulders. These tools with nominal diameters from 0.4 mm to 25 mm and

varied in form are intended for machining all types of materials used in the die and mold industry

such as tool and alloy steels, martensitic stainless steel, cast iron, etc. The tools differ in cutting

geometry, helix angle, number of flutes and length series (short to extra long) and perform all kinds

of milling: rough, semi-finish and finish operations.

ISCAR catalogs and leaflets contain detailed guidelines for using the solid carbide endmills in

shoulder milling. In general, recommended practice says that if the endmills with two flutes, which

have largest chip gullet characteristics, are intended mostly for rough shoulder machining, milling

slots and plunging; the multi-flute mills are usually used in finish applications with high requirements

of accuracy and surface quality.

Commonly, a tool choice and a cutting data depend on application requirements and workpiece

material. However, when speaking about feed limitations, it should be emphasized that the main

factors are not only tooth strength and tool rigidity, but also the ability of chip handling that is

defined by a chip gullet (a form of flute and its depth). Hence, due to the mentioned factors the

feed is limited by the nominal diameter and the number of flutes of a solid carbide endmill.

Endless cutting tool manufacturers from small shops to world-known companies produce solid

carbide endmills of the same sizes that often seem like copies of each other. However, in spite of

a formal resemblance, occasionally simply amazing, there is a great difference in performance and

tool life of the mills. The reason lies in carbide grades, grinding technology and of course, unique

features of cutting geometry.

Dry or wet

Dry machining (or using air as a coolant) is preferable for solid carbide endmills. In machining steels

and hard steels (ISO classes P and H correspondingly) by mills of IC900 and IC903 carbide grades,

a wet coolant is not recommended. If, however, an application requires wet cooling

(machining austenitic stainless steel, for instance), grade IC300 should be a first choice.

There are several carbide grades for ISCAR solid endmills.

The majority of the solid mills is produced from IC900 – a tough submicron substrate with PVD

TiAlN coating, which has wide-spectrum rough to finish applications at medium to high cutting

speeds in milling carbon, alloy, tool and stainless steel. Also, the grade is suitable for milling

hardened steel with hardness to HRC 55.

IC903 with an ultra-fine grain substrate with 12% cobalt content and PVD TiAlN coating can be

recommended for milling hardened steel, especially if its hardness is HRC 56-63 and even more.

The grade should not be used for heavy-duty machining.

IC300 is a tough submicron TiCN PVD coated grade that is suitable for machining steel

and stainless steel workpieces, specifically under unfavorable conditions, at low to medium

cutting speeds.

Uncoated fine-grain grade IC08 is aimed mainly at milling nonferrous materials.

Milling Tools

26

Table 10 Grade Selector for Solid Carbide Mills

- First choice

- Optional

ISO class IC900 IC903 IC300

P

:

M

K

H

Up to HRC 55

Above HRC 55

Within the rich and diversified family of ISCAR solid carbide square endmills (with 90˚ lead angle),

the following three lines have exceptional geometry.

The FINISHRED endmills feature 4 flutes with a 45˚ helix, two serrated teeth and two continuous

teeth, combine two geometries: rough (serrated teeth with chip splitting effect) and finish

(continuous teeth) and therefore sometimes are called “Two in One”. They enable running at rough

machining parameters, resulting in semi-finish or even finish surface quality. Such a single tool

(“One”) can replace the rough and finish endmills (“Two”), dramatically reducing cycle time and

power consumption, and increasing productivity. The unique tool design reduces vibrations at

heavy-duty applications; and the chip mixture from long and split short chips is evacuated more

easily, which is a good solution for machining cavities of dies and molds.

The CHATTERFREE endmills have 4 or 5 flutes and unequal tooth spacing. Due to the uneven

arrangement of the teeth these tools feature excellent dampening ability. They provide an effective

solution for low power machine tools with ISO40 or BT40 adaptations, which are popular in small

works involved in die and mold making. The mills are able machine full slots with 2xD depth.

The FINISHRED VARIABLE PITCH combines all the remarkable features of the two lines above.

Combining the lines together delivers a powerful hybrid solid carbide mill with extraordinary

performance. The user gets a “Three in One” rather than just a “Two in One” version of the

FINISHRED.

Regrinding solid carbide endmills

The progress in technology of grinding machine tools led to impressive achievements in regrinding

(resharpening) solid carbide endmills, allowing accurate restoration of cutting geometries of worn-out

tools. Reground mills still have shorter tool life due uncoated areas or problematic recoating.

However, the main reason of the efficiency losses is a reduction of a tool diameter as a result of

regrinding the tool relief surfaces. Regrinding the relief surfaces causes decreasing rake angles

and flute depth. Therefore, the tool cuts harder; its chip handling properties become worse.

On average, every 1% decrease of the tool diameter results in a decline of the tool performance

by 2%-3%, and from the definite reduction value the tool performance drops dramatically.

In order to avoid negative sides of regrinding it is very important to follow ISCAR’s instructions

regarding this operation.

Milling Tools

Die and Mold

27

Table 11 Maximal Depth of Slot Ap max, mm, for S.C. Mills of Standard Line

D, mm to 4 4-5 6-8 10-25

Ap max 0.3 D 0.4 D 0.4 D / D* 0.5 D / D*

*

with fz reduced by 50%

Table 12 Maximal Depth of Slot Ap max, mm, for FINISHRED Mills

D, mm to 4 4-5 6-8 10-25

Ap max 0.4 D 0.6 D 0.7 D / 1.2 D* 0.9 D / 1.5 D*

*

with fz reduced by 30%

Table 13 Maximal Depth of Slot Ap max, mm, for CHATTERFREE and

FINISHRED Variable Pitch Mills

D, mm to 4 4-5 6-8 10-25

Ap max 0.9 D D 1.2 D 2 D*

*

for D≥16 mm fz should be reduced by 20%

Cutting Data

Maximal Depth for Milling Full Slot

In full slot milling, the maximal depth depends not only on strength and stiffness of a mill but on

chip handling properties. In many cases milling deep slots demands considerable reduction of

feed per tooth in order to ensure proper chip evacuation. Using FINISHRED and FINISHRED

VARIABLE PITCH can substantially improve the mentioned difficulty.

The maximal depth should not exceed the values shown in Tables 11 to 13. The values relate to

slot milling in steel; and they should be doubled for workpieces from cast iron.

Milling Tools

28

Milling Square Shoulder: Dimensional Limitations

In rough to finish shoulder milling, depth of cut ap and width of cut ae can be estimated

in accordance with Table 14.

Starting Feeds and Speeds

The following tables specify estimated values for feed per tooth and cutting speeds referring to

FINISHRED, CHATTERFREE and FINISHRED Variable Pitch endmills.

The tables relate to rough and semi-finish milling. The recommendations regarding finish operations

are discussed on the next pages separately.

In case of unfavorable conditions (poor clamping, milling thin walls, high overhang), the table values

should be reduced by 20-30%.

ae

ap max

D ≤ 16 mm D > 16 mm

< 0.3 D 2 D 1.8 D

( 0.3…0.5) D 2 D 1.8 D

0.5 D < ae < 0.75 D 1.25 D 0.8 D

≥ 0.75 D Ap max*

Table 14 Shoulder Milling: Shoulder Size

- Recommended operational mode

*

Ap max as it specified in Tables 11-13

*

ISCAR material group in accordance with VDI 3323 standard

**

HRC 45-49

ISO Class

DIN/ISO 513

D, mm

Mat. Group* 1 2 3 4 5 6 8 10 12 16 20 25

P

1-4 0.008 0.020 0.030 0.040 0.055 0.065 0.080 0.085 0.092 0.138 0.145 0.155

5 0.008 0.020 0.028 0.038 0.055 0.065 0.077 0.082 0.090 0.130 0.137 0.148

6, 7 0.008 0.020 0.028 0.038 0.055 0.065 0.077 0.082 0.090 0.130 0.137 0.142

8, 9 0.008 0.019 0.028 0.038 0.050 0.060 0.072 0.077 0.085 0.130 0.137 0.142

10 0.008 0.017 0.025 0.036 0.048 0.058 0.070 0.072 0.082 0.125 0.130 0.137

11 0.008 0.012 0.022 0.032 0.045 0.055 0.065 0.065 0.077 0.110 0.120 0.132

M

12, 13 0.008 0.015 0.028 0.038 0.048 0.058 0.070 0.077 0.082 0.125 0.130 0.137

K

15-16 0.009 0.022 0.032 0.043 0.060 0.070 0.083 0.088 0.095 0.142 0.150 0.163

17-18 0.009 0.022 0.032 0.043 0.060 0.070 0.083 0.088 0.095 0.142 0.150 0.163

H

38.1** 0.022 0.028 0.032 0.038 0.040 0.045 0.055 0.060 0.065

38.2

39

Table 15 FINISHRED: Starting Feed fz, mm/tooth, for Mill Diameters D

Slot drills

Endmills that can cut straight down are also called “slot drills”. They have at least one center

cutting tooth, and their primary use is for milling key slots (“slot drilling”). Normally, the slot drills are

two-flute mills, but often they have three and sometimes even four flutes.

Milling Tools

Die and Mold

29

*

ISCAR material group in accordance with VDI 3323 standard

**

HRC 45-49

Table 16 CHATTERFREE and FINISHRED Variable Pitch

Starting Feed fz, mm/tooth, for Mill Diameters D

ISO Class

DIN/ISO 513

D, mm

Mat. Group* 3 4 5 6 8 10 12 16 20 25

P

1-4 0.022 0.032 0.045 0.055 0.058 0.060 0.065 0.078 0.088 0.110

5 0.022 0.032 0.040 0.050 0.055 0.058 0.060 0.065 0.077 0.100

6, 7 0.020 0.027 0.032 0.042 0.045 0.050 0.055 0.060 0.072 0.088

8, 9 0.019 0.027 0.032 0.036 0.038 0.042 0.050 0.055 0.065 0.075

10 0.016 0.022 0.027 0.030 0.032 0.038 0.045 0.050 0.060 0.067

11 0.012 0.016 0.022 0.027 0.030 0.035 0.038 0.045 0.055 0.060

M

12, 13 0.016 0.022 0.027 0.030 0.032 0.038 0.045 0.050 0.060 0.067

K

15-16 0.022 0.032 0.045 0.055 0.055 0.062 0.072 0.082 0.100 0.130

17-18 0.019 0.027 0.042 0.052 0.052 0.060 0.068 0.078 0.090 0.110

H

38.1** 0.016 0.020 0.022 0.025 0.027 0.032 0.035 0.045

38.2

39

*

ISCAR material group in accordance with VDI 3323 standard

**

HRC 45-49

Table 17 Starting Speed Vc, m/min (rough to semi-finish milling)

ISO Class

DIN/ISO 513

ISCAR

Mat. Group*

Slot

Milling

Shoulder

Milling

P

1 145 180

2-4 115 150

5 100 125

6 105 130

7-9 85 120

10 85 115

11 70 100

M 12, 13 80 110

K

15-16 130 160

17-18 125 150

H

38.1** 50 70

Ramp down milling and solid carbide endmills

We have already underlined that in die and mold making, where machining cavities and pockets are

so widely used, the ramp down ability is a very important feature of a milling tool. It stands to reason

that the slot drills have no limitations regarding a ramping angle, but the ramp down characteristics

of other endmills shall be thoroughly examined before planning and CNC programming the

corresponding milling operations (helical interpolation, for example) – refer to ISCAR catalogs

or product guidelines for appropriate data.

Milling Tools

30

*

ISCAR material group in accordance with VDI 3323 standard

**

HRC 45-49

Table 18 Starting Speed Vc, m/min (finish milling)

ISO Class

DIN/ISO 513

ISCAR

Mat. Group*

Vc,

m/min

P

1 280

2-4 200

5 170

6 190

7-9 170

10 165

11 120

M 12, 13 150

K

15-16 220

17-18 200

H

38.1 100

38.2 90

39 60

Milling Tools

Die and Mold

31

Finishing

Solid endmills as integral, monolith tools ensure high dimensional and form accuracy (tolerance

limits for a tool diameter, runout of teeth relative to the tool shank, etc.). Therefore, they fully meet

the requirements for finish milling (or finishing) of die and mold parts. The typical features of finishing

operations are high accuracy and surface quality of machined surface, and small allowances

(to 5% of a mill diameter and 0.1-0.2 mm for hardened steels). In finishing, the cutting speed is high

and the feed per tooth is low relative to rough and semi-finish operations. The tool strength allows

cutting with feeds greater than in Table 15 and 16, but due to insufficient surface finish it is

recommended to start cutting under the table values and then try to increase until the surface

roughness is enough.

Short or Extra-Long Reach?

Solid carbide endmills of the same type and nominal diameter vary in flute lengths and overall

lengths. The mills of short length ensure highest strength and rigidity whereas the extra long reach

mills are designed for deep cavities and high shoulders. As a rule, a series of standard endmills

comprise short, medium, long reach and extra long reach tools.

Example

It is required to mill a square shoulder of 3 mm width (ae) and 5 mm height (ap) in a mold block

from AISI/SAE 4340 steel with hardness HRC 34. The required roughness is Ra 2.5, the accuracy

requirements to straightness and flatness of the shoulder walls in accordance with ISO 2768-m

(medium). The available tool: solid carbide endmill EC-E4L 08-18/26W08CF63.

The machined material relates to the eighth material group (No.8).

The nominal diameter of the above mill is 8 mm (D), its cut length 18 mm (Ap).

The mill relates to the CHATTERFREE solid mill line.

The specified requirements to the milled surface are not high; ae/D = 3/8, ap<Ap, ap<2D (5<16);

hence the shoulder can be machined by one pass (Table 14).

From Table 16 starting feed fz =0.038 mm/tooth and from Table 17 starting cutting

speed Vc=120 m/min.

Feed per tooth or depth of cut?

In milling, metal removal rate, the litmus test of productivity, depends both on feed per tooth and