CAPA basics and

tools you could

use.

Presented by Trevor Schoerie

4 July, 2016

Slide 2 © PharmOut 2014

Outline

What is CAPA?

CAPA Tools

CAPA Workflow

Introduction

Slide 3 © PharmOut 2014

What is CAPA?

An improvement tool

used within good

manufacturing

practice (GMP)

principles and

various ISO

standards

Aims to prevent

issue recurrence

(corrective action) or

to prevent issue

occurrence

(preventative action)

CAPA is the core of

continuous

improvement

systems

“… CAPA is a quality assurance system, which addresses

quality events, which may occur or could be anticipated to

occur during healthcare products manufacturing.”

Slide 4 © PharmOut 2014

Correction, corrective action and

preventative action

Issue

Correction

Corrective Action

Preventative Action

Investigation

Slide 5 © PharmOut 2014

Key CAPA definitions

Corrective and Preventative Action

A systematic approach that includes actions needed to

correct (correction), avoid recurrence (corrective

action), and eliminate the cause of potential non-

conforming product and other quality problems

(preventative action)

CAPA

Action to eliminate a detected non-conformity.

Corrections typically are one-time fixes. A correction is

an immediate solution such as a repair or rework.

• Also known as remedial or containment action.

Correction

Slide 6 © PharmOut 2014

Key CAPA definitions

Action to eliminate the causes of a detected

nonconformity or other undesirable situation.

The corrective action should eliminate the

recurrence of the issue.

Corrective Action

Action to eliminate the causes of a potential

nonconformity or other undesirable potential

situation. Preventative action should prevent

the occurrence of the potential issue.

Preventative Action

Slide 7 © PharmOut 2014

Corrective or preventative?

• Product failing specifications

• Confirmed customer complaint

• Use of obsolete documents

• Audit finding

Name it corrective action only

if you already have a product

non-conformance or process

non-compliance

• Developing adverse trends from

monitoring systems

o Shifts

o Trends

o High Variability, and so on

Name it preventative action

whenever the product, process

or system is still in conformance

but you discover root cause with

the potential to create non-

conformities

• Changing to new material or new

design

• Implement new (enhanced) processes

Name it preventative action if

it is purely a recommendation to

enhance or improve any

product, process or system

Slide 8 © PharmOut 2014

The Quality System and CAPA

Quality System

• Defines processes to fulfil product requirements, customer satisfaction

and continuous improvement

QMS

• How quality policies are implemented and quality objectives are

achieved

Continuous Improvement

• Ongoing activities to evaluate and enhance the Quality System

Data Analysis

• Demonstrates the suitability and effectiveness of the QMS

Corrective Actions

• Identifies action needed to correct the causes of identified problems

Slide 9 © PharmOut 2014

Quality Systems Centre - CAPA

CAPA

Complaints

Customer &

Supplier Audits

Regulatory

Inspections

Stability

Environmental

Monitoring

Annual Product

Reviews

Continuous

Product

Verification

Internal

Audits

Deviations

Slide 10 © PharmOut 2014

Tools for identifying causes

Tools

• 5 Whys

• (Who, What, When,

Where, Why, How)

• Cause & Effect

• Problem Description

• Fault Tree Diagram

• Change Analysis

• Factor Analysis

• Brain storming

Tools

• Flow charting

• Root Cause Mapping

• Simple Checklists

• Fishbone diagrams

• Pareto chart

• Failure Mode & Effect

Analysis

• Change Analysis

Slide 11 © PharmOut 2014

Tool: 5 Why’s

• Step 1:

Establish a problem statement

E.g. “I was late to CAPA training today”

• Step 2:

Ask (and answer) the question “Why” 5 times

• Step 3:

The root cause becomes apparent by the 5

th

Why

Slide 12 © PharmOut 2014

Tool: Fishbone Diagram

Example:

CAUSES OF BURNT TOAST

No security on

Toaster Settings

Burnt

Toast

Equipment

Environment

People

Didn’t know correct

Toasting Setting

Didn’t read

instructions

Morning –

in a hurry

New Toaster

No Testing of

Settings done

before use

Procedure not

followed/

available

Process

Process not

tested/

validated

Material

Bread of

poor Quality/

Too dry

Slide 13 © PharmOut 2014

Tool: Problem Description

Date (week of)

Facts

October 12

Results within specifications

October 19

Floor maintenance housekeeping performed during the

weekend

October

26

High variability of results. The two balances were found

out of tolerance. Balances were calibrated.

November

2

Results within specifications

November

9

Results within specifications

November

16

Results within specifications

November

23

Results within specifications

November

30

Results within specifications

November

7

Floor maintenance housekeeping performed during the

weekend

November

14

High variability of results. The two balances were found

out of tolerance. Balances were calibrated.

November

21

Results within specifications

Slide 14 © PharmOut 2014

Tool: Change Analysis

0

10

20

30

40

50

60

70

80

February March April May June July August September October November December

Change Analysis Graph

Slide 15 © PharmOut 2014

Tool: Comparison Matrix

Is

Is not

Possible causes

Further action

Where

Johnstown

Plant

Cedarville

Plant

Equipment;

Inspection

procedures

Interview plant

management

What

Pit fragments

less than

5mm

No fragments

larger than

5mm

Improperly

maintained

pitters;

Performance data;

Line speeds

Analyse

maintenance

logs

and production

records

When

Production

after July 30

Production

before July 30

Change in fruit

characteristics;

Pitter

performance

Analyse

maintenance logs

and fruit

characteristics

Who

Smith;

Abbot farms

All other

farms

Soft fruit

Measure fruit

softness

Slide 16 © PharmOut 2014

Types of barriers:

Tool: Barrier Analysis

Physical barriers

• Separation among

manufacturing or

packaging lines

• Emergency power supply

• Dedicated equipment

• Barcoding

• Keypad controlling doors

• Software that prevents

further input if a field is

not completed

Administrative barriers

• Training and

certifications

• Clear procedures and

policies

• Adequate supervision

• Adequate load of work

• Use of checklist

• Verification of critical

task by a second person

Slide 17 © PharmOut 2014

Tool: Standard Checklists

Checklists are beneficial in providing a standard,

consistent list of potential sources of error.

For example:

• Was the correct procedure followed?

• Was the person trained in the procedure?

• Does the procedure match actual practice?

• Is this a recurring issue?

• Was there an equipment problem?

• Was the equipment calibrated?

Slide 18 © PharmOut 2014

Tool: Brainstorming

Brainstorming can be used in association with other

Root Cause Analysis tools

Brainstorming is a method for

generating a large number of

creative ideas in a short period

of time

Approach:

• Unstructured shout-out ideas

• Thinking “outside the box”

• Structured rotation around the room for ideas

Slide 19 © PharmOut 2014

Chronology

Causes Of Burnt Toast

Time

Prior to today

Used old Toaster

Last night

Wife introduced New Toaster

8am

Awoke

after late night

8.10

Removed bread from Pantry. Noted old bread was dry

8.15

Inserted bread to toaster as per previous day

8.16

Depressed

Toasting lever

8.20

Toaster smoking, toast burnt

8.21

Pressed

abort and removed burnt toast

8.22

Recognised Toaster was new

8.23

Called wife to locate instructions. Sitting beside toaster

8.24

Went to work with no Breakfast

Slide 20 © PharmOut 2014

Tool: Comparison Matrix

Comparison Matrix

• Tool aimed at focussing on the key areas implicated in the

problem and remove areas of investigation not implicated

Slide 21 © PharmOut 2014

Tool: Fault Tree Analysis

Fault-Tree Analysis

• Tool used to identify the key activity streams that may have led to the

problem being displayed

• Helps identify the true root cause(s)

This method is similar to the Root Cause

Mapping

Slide 22 © PharmOut 2014

Root Cause Analysis (RCA) tips

Root Cause Analysis (RCA) is a key element to a site’s

Quality System.

Important considerations include:

• Don’t forget the past – has this occurred previously?

• Don’t stop at the first plausible explanation – complete

the process to eliminate

all

other possible causes

• There may be

more than one

root cause

• If you do not find a confirmed root cause, address the

potential root causes and monitor the issue

• Monitor – follow-up on implemented actions

Slide 23 © PharmOut 2014

CAPA work flow

Identify

Root Cause

Assess the

significance

Assess the

risk

Assess the

potential

for

recurrence

Slide 24 © PharmOut 2014

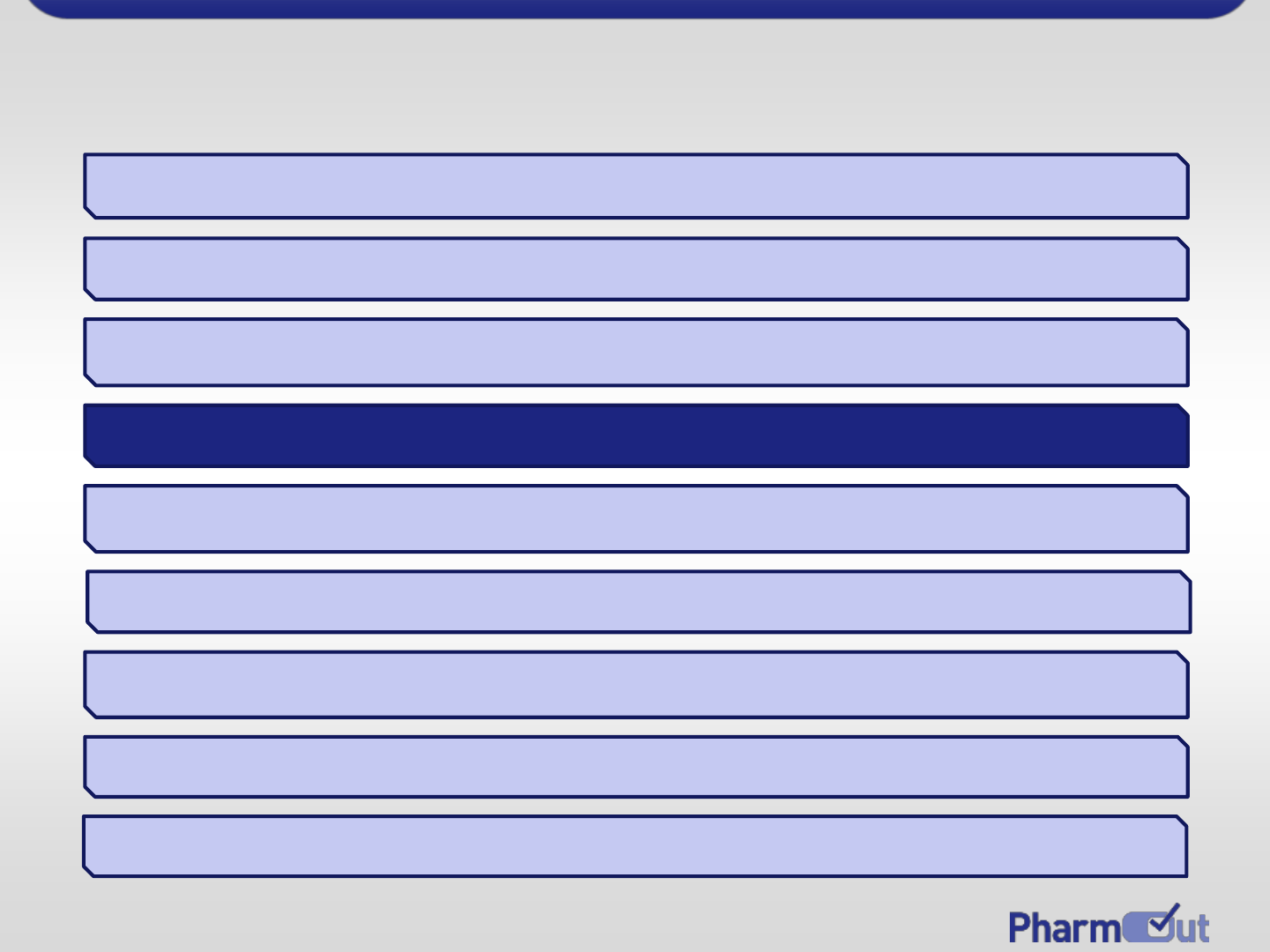

CAPA form

Section 1– Issue Details

Section 2 – Immediate actions

Section 3 – Investigation

Section 5 – Corrective actions

Section 6 – Preventative actions

Section 7 – CAPA Implementation Plan

Section 8 – CAPA Effectiveness Check and Summary

Section 4 – Root Cause

Section 9 – Approval

Slide 25 © PharmOut 2014

Describe the issue

Slide 26 © PharmOut 2014

CAPA Form

Section 1– Issue Details

Section 2 – Immediate actions

Section 3 – Investigation

Section 5 – Corrective actions

Section 6 – Preventative actions

Section 7 – CAPA Implementation Plan

Section 8 – CAPA Effectiveness Check and Summary

Section 4 – Root Cause

Section 9 – Approval

Slide 27 © PharmOut 2014

List the immediate actions taken

Slide 28 © PharmOut 2014

CAPA Form

Section 1– Issue Details

Section 2 – Immediate actions

Section 3 – Investigation

Section 5 – Corrective actions

Section 6 – Preventative actions

Section 7 – CAPA Implementation Plan

Section 8 – CAPA Effectiveness Check and Summary

Section 4 – Root Cause

Section 9 – Approval

Slide 29 © PharmOut 2014

Describe investigation undertaken

Slide 30 © PharmOut 2014

CAPA Form

Section 1– Issue Details

Section 2 – Immediate actions

Section 3 – Investigation

Section 5 – Corrective actions

Section 6 – Preventative actions

Section 7 – CAPA Implementation Plan

Section 8 – CAPA Effectiveness Check and Summary

Section 4 – Root Cause

Section 9 – Approval

Slide 31 © PharmOut 2014

List the root cause(s) of issue

Slide 32 © PharmOut 2014

CAPA Form

Section 1– Issue Details

Section 2 – Immediate actions

Section 3 – Investigation

Section 5 – Corrective actions

Section 6 – Preventative actions

Section 7 – CAPA Implementation Plan

Section 8 – CAPA Effectiveness Check and Summary

Section 4 – Root Cause

Section 9 – Approval

Slide 33 © PharmOut 2014

List proposed corrective actions

Slide 34 © PharmOut 2014

CAPA Form

Section 1– Issue Details

Section 2 – Immediate actions

Section 3 – Investigation

Section 5 – Corrective actions

Section 6 – Preventative actions

Section 7 – CAPA Implementation Plan

Section 8 – CAPA Effectiveness Check and Summary

Section 4 – Root Cause

Section 9 – Approval

Slide 35 © PharmOut 2014

List proposed preventative actions

Slide 36 © PharmOut 2014

CAPA Form

Section 1– Issue Details

Section 2 – Immediate actions

Section 3 – Investigation

Section 5 – Corrective actions

Section 6 – Preventative actions

Section 7 – CAPA Implementation Plan

Section 8 – CAPA Effectiveness Check and Summary

Section 4 – Root Cause

Section 9 – Approval

Slide 37 © PharmOut 2014

Detail the CAPA Implementation Plan

Slide 38 © PharmOut 2014

Detail the CAPA Implementation Plan

Slide 39 © PharmOut 2014

CAPA Form

Section 1– Issue Details

Section 2 – Immediate actions

Section 3 – Investigation

Section 5 – Corrective actions

Section 6 – Preventative actions

Section 7 – CAPA Implementation Plan

Section 8 – CAPA Effectiveness Check and Summary

Section 4 – Root Cause

Section 9 – Approval

Slide 40 © PharmOut 2014

Describe post-implementation

effectiveness checks

Slide 41 © PharmOut 2014

Describe post-implementation

effectiveness checks

Slide 42 © PharmOut 2014

CAPA Form

Section 1– Issue Details

Section 2 – Immediate actions

Section 3 – Investigation

Section 5 – Corrective actions

Section 6 – Preventative actions

Section 7 – CAPA Implementation Plan

Section 8 – CAPA Effectiveness Check and Summary

Section 4 – Root Cause

Section 9 – Approval

Slide 43 © PharmOut 2014

Final CAPA Approval

Slide 44 © PharmOut 2014

10 common mistakes

01 Timeliness (lack of)

02 Everything is an isolated event

03 Root cause not identified

04 Correcting the symptom instead of the cause

05 Lack of interim corrective actions

06 Root cause identified by not corrected

07 Lack of true preventative action

08 Lack of effectiveness verification

09 Multiple CAPA systems without correlation

10 Abuse of human error and retraining

Slide 45 © PharmOut 2014

Thank you for your time.

Questions?

Trevor Schoerie

trevor.schoerie@pharmout.net

Managing Director

www.pharmout.net