SAMPLE COLLECTION AND EVALUATION OF VAPOR

INTRUSION TO INDOOR AIR

FOR REMEDIAL RESPONSE, RESOURCE CONSERVATION

AND RECOVERY ACT AND VOLUNTARY ACTION

PROGRAMS

Division of Environmental Response and Revitalization

March 2020

i

Acknowledgements

This updated guidance was developed by a workgroup of Ohio Environmental Protection

Agency (EPA) staff.

Workgroup members included:

Michael Allen

Gavin Armstrong

Sarah Beal

Chris Bulinski

Dawn Busalacchi

Corin Fogle

Erik Hagen

Melissa Langton

Chuck Mellon

Chris Osborne

Carrie Rasik

Lisa Shook

Vanessa Steigerwald-Dick

Brian Tucker

Katie Weyrauch

The following guidance document represents an update to the May 2010 Ohio EPA

document of the same title and supersedes any and all previous vapor intrusion guidance

documents presented by the agency. This update reflects the Ohio EPA Division of

Environmental Response and Revitalization’s (DERR) latest understanding of

appropriate policies regarding vapor intrusion. The document was developed using

established guidance from the United States (U.S.) Environmental Protection Agency

(EPA), the Interstate Technology Resource Council (ITRC), American Society of Testing

and Materials (ASTM), and other states, modified for the purposes of complying with

remedial response, resource conservation and recovery act and voluntary actions in Ohio.

Special thanks to the California Environmental Protection Agency, Department of Toxic

Substances Control, for permission to use the Interim Final Guidance for the Evaluation

and Mitigation of Subsurface Vapor Intrusion to Indoor Air, December 2004, as a

template. In some instances, exact phrasing from California’s guidance was used.

Disclaimer

This guidance was developed solely for sites under the oversight of Comprehensive

Environmental Response, Compensation, and Liability Act of 1980 (CERCLA), the

Resource Conservation and Recovery Act program (RCRA), and the Voluntary Action

Program (VAP), carried out under the supervision of Ohio EPA DERR. In this document

sites managed under CERCLA and RCRA will be characterized as remedial programs

ii

(RP). Use of this guidance for other Ohio EPA programs or other state agency programs

may not be appropriate.

The guidance serves as an instructional tool for the investigation and evaluation of vapor

intrusion at sites in Ohio. It is not meant to be a regulatory document and any statements

provided herein are not legally binding.

iii

TABLE OF CONTENTS

LIST OF ACRONYMS .....................................................................................................vi

EXECUTIVE SUMMARY ................................................................................................. x

1.0 INTRODUCTION .................................................................................................... 1

2.0 SCOPE .................................................................................................................. 1

3.0 VAPOR INTRUSION EVALUATION ...................................................................... 2

3.1 Initial Vapor Intrusion Assessment ...................................................................... 2

3.2 Conceptual Site Model ........................................................................................ 4

3.3 Data Quality Objective Process and Developing a Sample Plan ........................ 6

4.0 SOIL GAS AND SUB-SLAB VAPOR SAMPLING PROCEDURES ........................ 9

4.1 Soil Gas and Sub-Slab Vapor Sample Collection and Analysis .......................... 9

4.2 Analytical Detection Limits ................................................................................ 11

4.3 Soil Gas Sampling ............................................................................................ 11

4.4 Soil Gas Probes ................................................................................................ 13

4.5 Sub-Slab Vapor Sampling and Data ................................................................. 15

4.6 Sampling Basements with Dirt Floors and Crawl Spaces ................................. 17

4.7 Leak Testing ..................................................................................................... 18

4.8 Passive Soil Gas (Exterior or Sub-Slab) Sampling ........................................... 21

5.0 INDOOR AIR SAMPLING .................................................................................... 22

5.1 Site Inspection, Product Inventory and Field Screening ................................... 23

5.2 Indoor Air Sample Collection and Analysis ....................................................... 23

6.0 GROUND WATER MONITORING AND EVALUATION ....................................... 26

6.1 Well Placement ................................................................................................. 26

6.2 Screen Placement ............................................................................................ 27

6.3 Screen Lengths ................................................................................................. 27

6.4 Ground Water Sampling ................................................................................... 27

6.5 Soil Gas Confirmation of Ground Water Concentration .................................... 28

6.6 Other Factors .................................................................................................... 28

7.0 BULK SOIL .......................................................................................................... 28

8.0 DATA EVALUATION AND ANALYSIS ................................................................. 29

8.1 Vapor Intrusion Screening Levels ..................................................................... 29

8.2 Bulk Soil Data ................................................................................................... 30

iv

8.3 Ground Water Data Screening .......................................................................... 31

8.4 Soil Gas and Sub-Slab Vapor Data Screening ................................................. 31

8.5 Indoor Air Data Evaluation ................................................................................ 32

8.6 Background Source Evaluation ......................................................................... 32

8.7 Occupational Exposure Limits .......................................................................... 32

9.0 VAPOR INTRUSION FROM PETROLEUM RELEASES ..................................... 33

9.1 Petroleum Release Characterization and Phase Partitioning ........................... 34

9.2 Lateral Inclusion Zone ...................................................................................... 35

9.3 Vertical Separation Distance............................................................................. 35

9.4 Ground Water Flow and Dissolved Plumes ...................................................... 36

9.5 Compliance with BUSTR .................................................................................. 36

10.0 MODELING THE VAPOR INTRUSION PATHWAY ........................................... 36

10.1 U.S. EPA Vapor Intrusion Screening Level Calculator .................................... 37

10.2 Overview of the Use of Fate and Transport Models in Ohio EPA ................... 38

10.3 Overview of U.S. EPA’s Johnson and Ettinger Model ..................................... 38

10.4 BioVapor ......................................................................................................... 39

11.0 EVALUATION OF IMMINENT HAZARD IN AN EXISTING BUILDING .............. 39

11.1 Potential Imminent Hazard Conditions ............................................................ 40

11.2 Explosive Hazard ............................................................................................ 40

12.0 RISK CHARACTERIZATION ............................................................................. 41

12.1 Determining Applicable Risk Goals and the Need for Further Evaluation ....... 41

12.2 Use of Maximum Contaminant Levels (MCLs) ................................................ 42

12.3 Use of BUSTR Petroleum Standards .............................................................. 42

13.0 REMEDY ............................................................................................................ 43

13.1 Remedy Selection and Implementation Considerations ................................. 43

13.2 Remediation of Environmental Media ............................................................. 46

13.3 Institutional Controls ....................................................................................... 46

13.4 Engineering Controls ...................................................................................... 46

13.5 Active Sub-Slab Depressurization Systems .................................................... 47

13.6 Heating, Ventilation, Filtration Units and Air Conditioning (HVAC) Measures . 49

13.7 Passive Engineering Controls ......................................................................... 50

13.8 Monitoring Requirements for Engineering Controls ........................................ 51

v

13.9 Post-Mitigation and Seasonal Monitoring ....................................................... 51

13.10 Termination of Engineering Controls ............................................................ 52

13.11 Owner Documentation/Notification of Engineering Controls ......................... 52

14.0 LONG-TERM MANAGEMENT AND EXIT STRATEGY AT VAPOR INTRUSION

SITES ........................................................................................................................ 53

14.1 Long-Term Management ................................................................................ 53

14.2 Ground Water, Soil Gas, Sub-Slab Vapor and Differential Pressure

Monitoring/Sampling ............................................................................................... 54

14.3 Passive Mitigation System Efficacy Verification .............................................. 54

14.4 Environmental Covenants and Deed Restrictions ........................................... 55

14.5 Exit Strategy ................................................................................................... 55

15.0 CITATIONS AND REFERENCES ...................................................................... 57

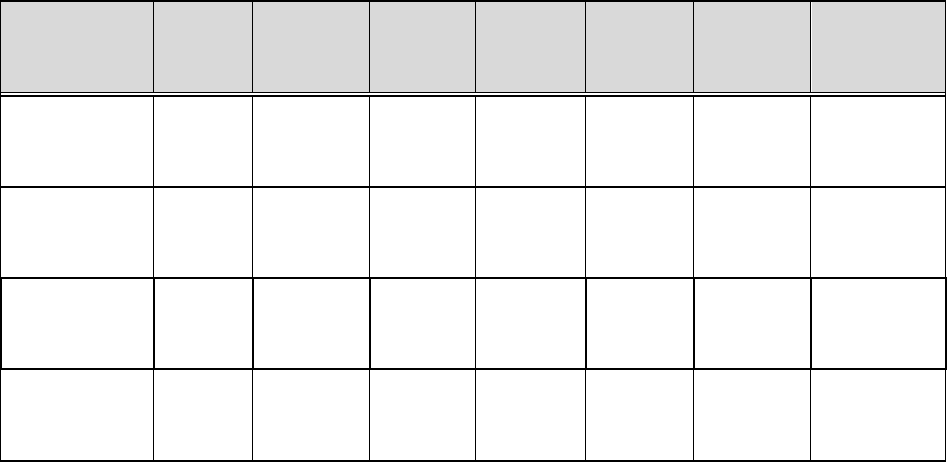

LIST OF FIGURES

Figure 1. Stepwise Approach for Evaluating the Vapor Intrusion Pathway ......................xi

Figure 2. Examples of Soil Gas Sampling Probes ........................................................ 13

Figure 3. Permanent Soil Gas Probe Schematic .......................................................... 15

Figure 4. Example of a Sub-Slab Vapor Probe ............................................................ 17

Figure 5. Schematic of a Summa Canister ................................................................... 25

Figure 6. Petroleum Distillation .................................................................................... 34

Figure 7. Schematic of PVI Scenario with LNAPL ........................................................ 36

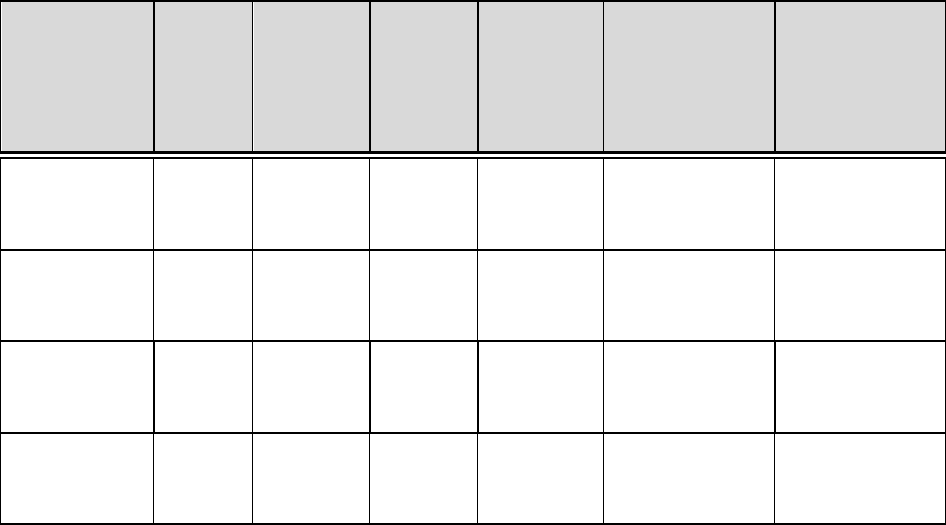

LIST OF TABLES

Table 1. Common Tracers Advantages and Disadvantages ......................................... 20

Table 2. Comparison of Indoor Air and Sub-Slab Vapor Sampling Conditions to Bias

Sampling to the Highest Potential Concentrations* ....................................................... 24

Table 3. Comparison of Mitigation Technologies .......................................................... 45

vi

LIST OF APPENDICES

APPENDIX A. Vapor Intrusion Conceptual Site Model Checklist .................................. 61

APPENDIX B. Special Considerations for Evaluating Residential Properties ............... 63

APPENDIX C. FSOPs ................................................................................................... 64

APPENDIX D. Soil Gas Probe Field Data Report Form .............................................. 106

APPENDIX E. Indoor Air/Sub-Slab Sampling Form .................................................... 107

APPENDIX F. Soil Gas and Sub-Slab Vapor Analytical Methods and Reporting Limit

Ranges ........................................................................................................................ 113

APPENDIX G. Comparison of Tubing Type to Vapor Absorption ................................ 116

LIST OF ACRONYMS

AC Alternating Current

ADS Active Depressurization System

AF Attenuation Factor

APU Air Purifying Unit

AST Aboveground Storage Tank

ASTM American Society of Testing and Materials

BGS Below Ground Surface

BTEX Benzene Toluene Ethylbenzene Xylene

BUSTR Bureau of Underground Storage Tank Regulations

CERCLA Comprehensive Environmental Response, Compensation, and Liability

Act

COCs Chemicals of Concern

CP Certified Professional

CPRG Closure Plan Review Guidance

CSM Conceptual Site Model

CVAFS Cold Vapor Atomic Fluorescence Spectrometry

vii

CV/AA Cold Vapor/Atomic Absorption

DERR Division of Environmental Response and Revitalization

DNAPL Dense Non-Aqueous Phase Liquid

DQOs Data Quality Objectives

EC Environmental Covenant

ECD Electron Capture Detector

ELCR Excess Lifetime Cancer Risk

EPA Environmental Protection Agency

FFS Federal Facilities Section

FID Flame Ionization Detector

FSOP Field Standard Operating Procedure

GC/MS Gas Chromatograph/Mass Spectrometer

HASP Health and Safety Plan

HEPA High-Efficiency Particulate Air

HQ Hazard Quotient

HRV Heat Recovery Ventilation

HVAC Heating, Ventilation and Air Conditioning

IDLH Immediately Dangerous to Life and Health

IRIS Integrated Risk Information System

ITRC Interstate Technology Resource Council

J&E Model Johnson and Ettinger Vapor Intrusion Model

LDPE Low Density Polyethylene

LEL Lower Explosive Limit

LNAPL Light Non-Aqueous Phase Liquid

LPM Liters Per Minute

MIP Male Iron Pipe

NAPL Non-Aqueous Phase Liquid

NCP National Contingency Plan

viii

NJDEP New Jersey Department of Environmental Protection

O&M Operation and Maintenance

OAC Ohio Administrative Code

OD Outer Diameter

ODH Ohio Department of Health

Ohio EPA Ohio Environmental Protection Agency

ORC Ohio Revised Code

OSHA Occupational Safety and Health Administration

OSI Office of Special Investigation

OSWER Office of Solid Waste and Emergency Response (U.S. EPA)

PCBs Polychlorinated Biphenyls

PCE Tetrachloroethylene

PDS Passive Depressurization System

PEL Permissible Exposure Limit

PHC Petroleum Hydrocarbons

PID Photoionization Detector

PPB Parts per Billion

PPBV Parts per Billion Volume

PPM Parts per Million

PPMV Parts per Million Volume

PTFE Polytetrafluoroethylene

PVI Petroleum Vapor Intrusion

QA Quality Assurance

QC Quality Control

RAGS Risk Assessment Guidance for Superfund

RCRA Resource Conservation and Recovery Act

RI/FS Remedial Investigation/Feasibility Study

RP DERR Remedial Programs (CERCLA and RCRA)

ix

RSL Regional Screening Level

SARA Superfund Amendments and Reauthorization Act

SCIA Source Control Interim Action

SIFU Site Investigation Field Unit (Ohio EPA)

SIM Selected Ion Monitoring

SOP Standard Operating Procedure

SSWP Site-Specific Work Plan

STEL Short-Term Exposure Limits

SVE Soil Vapor Extraction

TCD Thermal Conductivity Detector

TCE Trichloroethylene

TPH Total Petroleum Hydrocarbons

TSCA Toxic Substances Control Act

UPUS Unrestricted Potable Use Standards

U.S. EPA United States Environmental Protection Agency

UST Underground Storage Tank

VAP Voluntary Action Program

VI Vapor Intrusion

VISL Vapor Intrusion Screening Level (U.S. EPA)

VOA Volatile Organic Analysis

VOCs Volatile Organic Compounds

x

EXECUTIVE SUMMARY

The intrusion of volatile chemicals from the subsurface into buildings is one of many

exposure pathways that must be considered when assessing risk to human health from

contamination. The Ohio EPA Division of Environmental Response and Revitalization

(DERR) recommends a stepwise approach and sampling methodologies for evaluating

vapor intrusion, as described in this document.

Ohio EPA DERR currently administers four environmental media clean-up programs: the

Voluntary Action Program (VAP), the Comprehensive Environmental Response,

Compensation, and Liability Act of 1980 (CERCLA) program, the Federal Facilities

Section (FFS) and the Resource Conservation and Recovery Act (RCRA) program. In

this document sites managed under CERCLA, FFS and RCRA will be characterized as

Remedial Programs (RP).

The VAP is semi-privatized and operates under Ohio Revised Code (ORC) 3746 and

Ohio Administrative Code (OAC) 3745. Site assessments and clean-ups in the VAP are

conducted by Certified Professionals certified by the program. Site clean-ups under the

RP are directed by Ohio EPA staff, and follow the requirements of CERCLA as modified

by the Superfund Amendments and Reauthorization Act, and the National Contingency

Plan. Corrective Actions and Unit Closures are directed by Ohio EPA staff and follow the

requirements of RCRA and subsequent amendments. There are differences between the

programs and their methods of assessment, decision points and remedy selection.

However, this guidance applies to all Ohio EPA DERR clean-up programs unless

explicitly noted.

Stepwise Approach

If volatile chemicals are present in the subsurface at a site, then the vapor intrusion

pathway should be evaluated along with other complete or anticipated exposure

pathways identified through the site assessment. Due to the complexity of vapor intrusion,

many professional disciplines may be needed to evaluate and mitigate the exposure.

Ohio EPA recommends evaluating multiple lines of evidence in a systematic, stepwise

approach depicted in Figure 1 (the flowchart) for the evaluation of the vapor intrusion

pathway. It is not necessary to investigate a site for potential vapor intrusion risk in the

order presented in this guidance. For sites where the environmental release history is

unknown, the stepwise approach should be most useful and effective. However, many

sites in Ohio EPA DERR programs have been assessed in some manner prior to

investigating potential vapor intrusion issues. Therefore, entering the flowchart (Figure 1)

at various steps may be appropriate.

xi

Figure 1. Stepwise Approach for Evaluating the Vapor Intrusion Pathway

xii

Step 1 Conduct the site assessment.

The site assessment is paramount to determining whether the potential for the vapor

intrusion pathway exists at a site. A site assessment involves examining current and

former activities such as, the types of chemicals used, stored and managed at the site,

as well as the administrative history to determine whether releases occurred or if there

was potential for releases of hazardous substances or petroleum to environmental media

(i.e., soil, ground water, soil gas, sub-slab vapor or indoor air). A site walkover/inspection

is also necessary.

Step 2 Determine if there is the potential for any volatile and toxic chemicals in soil

or ground water.

Chemicals in the subsurface must be both sufficiently volatile and toxic to present a vapor

intrusion risk. If there is no reason to believe that a release of a volatile chemical may

have affected the site, then the information supporting this decision should be

documented and the vapor intrusion pathway does not need further evaluation.

Step 3 Determine if there is a potentially complete vapor intrusion pathway.

If there was a release, or a release of any sufficiently volatile and toxic chemicals was

possible, then develop an investigative workplan that includes a Conceptual Site Model

(CSM) for evaluating the vapor intrusion pathway. The potential for a complete vapor

intrusion pathway depends on factors such as current or future land use, distance

between contamination and existing or proposed buildings, preferential pathways, and

whether contaminant plumes are at steady state. The CSM is not static, but continually

refined and revised based on data and other information collected at the site.

Step 4 Sample environmental media.

After the vapor intrusion pathway is determined to be potentially complete, sample

environmental media (i.e., soil, ground water, soil gas, sub-slab vapor or indoor air) and

determine if concentrations indicate a vapor source is present and/or if vapors have

infiltrated a building. Data from only one environmental medium is generally not sufficient

to fully assess the vapor intrusion exposure pathway. A multiple lines of evidence

approach is preferred to evaluate pathway completeness from all environmental media,

to assess the complete and potentially complete vapor intrusion exposure pathway to

human receptors, and to reduce uncertainties.

Step 5 Evaluate data and determine if data evaluation indicates the possibility of

an imminent hazard.

A number of tools can be used at this stage to determine if the vapor intrusion pathway

poses a potential unacceptable risk for building occupants. Compare ground water, soil

gas, and/or sub-slab vapor concentrations to vapor intrusion screening levels (VISLs) that

correspond to a non-cancer hazard of 1 and an excess lifetime cancer risk (ELCR) of 1E-

5. Update the CSM depending on the outcome of data evaluation. If data indicate the

xiii

possibility of an imminent hazard, which is any condition which poses an immediate risk

of harm to public health, safety, or the environment, Ohio EPA should be contacted as

soon as possible and the volunteer should be prepared to move to Steps 7 and/or 8, as

appropriate, in a timely manner.

Step 6 Evaluate the potential risk and hazard from the vapor intrusion pathway.

For RP sites, if data evaluation indicates that concentrations are below screening values,

those chemicals of concern (COCs) are eliminated from further vapor intrusion

assessment. For VAP properties, if the concentrations are below screening values the

vapor intrusion pathway may not be complete for that COC, however the data and

screening values must be used to calculate incremental site-wide risk.

Step 7 If data evaluation indicates risk or hazard goals are or may be exceeded,

then additional data may be collected, or a remedy may be implemented (see Step

8).

If data evaluation indicates a potential for unacceptable human health risk, then additional

data collection may be necessary to conduct a risk assessment, evaluate lines of

evidence, and/or determine what, if any, remedy is needed. Further investigation may

include the following:

• Collecting data to define physical and chemical parameters for site-specific soil

using recommended test methods.

• Collecting soil gas samples to define the vapor plume at sites where buildings do

not exist.

• Collecting sub-slab vapor samples or crawl space samples at an existing building.

• Collecting indoor air samples in conjunction with sub-slab vapor or soil gas

samples.

• Additional evaluation of the environmental data may be needed to derive an

exposure point concentration for use in a property-specific risk assessment.

Step 8 Remediation, Mitigating Indoor Air Exposure and/or Conducting Long-Term

Monitoring.

If data evaluation indicates the potential for unacceptable human health risk, there are

several remedies that may be considered to mitigate vapor intrusion to indoor air. For

VAP sites, the volunteer selects the remedy. For RP sites, the remedy is selected

following procedures outlined in CERCLA as amended by SARA and the NCP and may

be defined by site-specific orders.

Potential remedies may include:

• Removing vapor-forming chemical contamination through site remediation.

• Installing passive or active vent systems (existing buildings).

xiv

• Installing passive and/or active vent systems/membrane systems (future

buildings).

• Designing ventilation systems to mitigate indoor air concentrations (HVAC).

• Using institutional controls to restrict structures or land use on contaminated

property.

• Implementing and monitoring of appropriate engineered remedies to prevent or

mitigate exposure through vapor intrusion. Monitoring of engineered controls must

continue until risk-based clean-up levels as measured in environmental media

have been met.

For any remedy chosen for a site, long-term monitoring of soil gas and/or indoor air may

be necessary under an Operations and Maintenance (O&M) plan. The frequency of the

monitoring will depend upon site-specific conditions and the degree of vapor-forming

chemical contamination.

1

1.0 INTRODUCTION

Volatile chemicals in soil or ground water can migrate through the subsurface, enter

buildings, and potentially cause an unacceptable chemical exposure for building

occupants. If volatile chemicals are present at a site, Ohio EPA DERR requires that

potential risk from vapor intrusion be included in the CSM and the potentially complete

pathway investigated. This guidance provides a framework for site characterization and

investigation of the vapor intrusion pathway.

Evaluation of the vapor intrusion to indoor air pathway may involve sampling

environmental media to evaluate and characterize subsurface chemical releases, using

screening models to predict indoor air concentrations, and usually includes conducting

indoor air sampling. This guidance outlines the technical aspects of evaluating the vapor

intrusion pathway and provides recommendations for elements that should be included

in a site investigation. This guidance is not intended to provide detailed information on

conducting a baseline or property specific risk assessment.

Due to the complexity of vapor intrusion, many professionals of varying disciplines may

be needed to evaluate and mitigate exposure, such as geologists, risk assessors,

engineers, HVAC specialists, Certified Industrial Hygienists, and risk communication

specialists. Accordingly, an appropriate project team should be gathered when evaluating

vapor intrusion issues. Ohio EPA DERR anticipates that this guidance will be used by

regulators, responsible parties, environmental consultants, community groups, and

property developers.

Vapor intrusion is a developing field and it is anticipated that some of the procedures and

practices within this guidance will change as understanding of vapor intrusion progresses.

Ohio EPA DERR will update this document as needed to accommodate refinements and

advances in the field of vapor intrusion.

2.0 SCOPE

This guidance provides options of technically defensible and consistent approaches for

evaluating the vapor intrusion to indoor air pathway, but it is not comprehensive, nor does

it impose any requirements or obligations on the regulated community. Other technically

equivalent sampling and engineering procedures exist and those investigating vapor

intrusion may use other technically sound approaches. Furthermore, this guidance does

not alleviate a volunteer or potentially responsible party from any obligations that U.S.

EPA may require.

This guidance document provides procedures to evaluate the vapor intrusion to indoor air

pathway only. All other media characterization and evaluation of complete exposure

pathways at a site must be done in accordance with the rules or procedures of the

appropriate Ohio EPA DERR programs. This guidance is meant to provide information to

fully characterize the potential risk from vapor intrusion at DERR sites.

2

This guidance assists in addressing, but is not limited to, the following questions:

• What sites are candidates for potential risk from vapor intrusion to indoor air?

• What site-specific data are needed to conduct a vapor intrusion evaluation?

• What methods are recommended for sampling subsurface media and indoor air?

• Should indoor air sampling be conducted?

• What are the data requirements for an evaluation of the vapor intrusion pathway?

• What measures are available to mitigate indoor air exposures?

3.0 VAPOR INTRUSION EVALUATION

The following text describes the stepwise approach for evaluating vapor intrusion found

in Figure 1 (the flowchart). The stepwise approach in this guidance document is meant to

be flexible and may be tailored to site-specific circumstances. Pathway evaluation may

begin at any step in the flowchart provided that the data collection and the CSM clearly

justify entry into that step. However, most vapor intrusion pathway evaluation decisions

and determinations regarding the need for remedial activities and long-term mitigation are

not made using indoor air sampling results alone because a vapor intrusion exposure

pathway is assumed to be complete unless demonstrated otherwise. For this reason, it is

preferred to also have data collected from soil, ground water, soil gas, and/or sub-slab

vapor when making decisions and drawing conclusions about a potential vapor intrusion

pathway from indoor air sampling results.

3.1 Initial Vapor Intrusion Assessment

The steps outlined in the flowchart apply at sites whether or not buildings are currently

present and/or occupied. Current buildings and future building scenarios, as appropriate,

will determine sampling strategy and data evaluation. While the assessment process is

presented in a stepwise fashion, the vapor intrusion pathway is generally evaluated in an

iterative manner and steps may be repeated.

Flowchart Step 1 and Step 2: Conduct the site assessment and determine if there is a

potentially complete vapor intrusion pathway

A comprehensive evaluation of the current and historical operations at a site should be

conducted to identify potential or known releases of volatile chemicals to subsurface

environmental media. A complete compilation of site information is essential for

identifying all potential vapor intrusion exposure pathways. For VAP properties, a

complete Phase I property assessment must be conducted in accordance with the Ohio

Administrative Code (OAC) 3745-300-06. RP sites may use ASTM E1527-13 (or most

recent version) Standard Practice for Environmental Site Assessments: Site assessment

Environmental Site Assessment Process (ASTM, 2013), DERR’s Closure Plan Review

Guidance (CPRG) (Ohio EPA, 2017) or other relevant CERCLA and RCRA guidance.

For simplicity, this guidance will not repeat the requirements necessary to conduct a site

assessment. However, using the site assessment information when developing a CSM is

3

a necessary component of this guidance. See the discussion in Step 4 for more details

on CSM components for evaluating the vapor intrusion pathway.

U.S. EPA’s June 2015 OSWER Technical Guide for Assessing and Mitigating the Vapor

Intrusion Pathway from Subsurface Vapor Sources to Indoor Air (VI Guidance) (U.S. EPA,

2015b) states that the chemicals in the subsurface must be both sufficiently volatile and

toxic to present a vapor intrusion risk. A chemical is considered “volatile” if its:

• Vapor pressure is greater than 1 millimeter of mercury (mmHg); or

• Henry’s law constant is greater than 10

-5

atmosphere-meter cubed per mole

(atm m

3

mol

-1

).

In addition to being sufficiently volatile, a chemical must be potentially toxic to present a

vapor intrusion risk. A volatile chemical may be considered toxic in regard to vapor

intrusion if:

• The vapor concentration of the pure component exceeds the target indoor

air concentration, when the subsurface vapor source is in soil; or

• The saturated vapor concentration exceeds the target indoor air risk level,

when the subsurface vapor source is in ground water.

In addition to researching a chemical’s physical-chemical properties, the most recent

version of the U.S. EPA Vapor Intrusion Screening Level (VISL) calculator can be used

as a tool to help determine if a chemical meets the criteria of sufficiently volatile and toxic

and should be included in a vapor intrusion investigation. Chemicals that are sufficiently

volatile and toxic in regard to vapor intrusion are referred to in this guidance document as

vapor-forming chemicals. For additional information on identifying vapor-forming

chemicals, please refer to Chapter 3 of U.S. EPA’s June 2015 OSWER Technical Guide

for Assessing and Mitigating the Vapor Intrusion Pathway from Subsurface Vapor

Sources to Indoor Air (U.S. EPA, 2015b).

If any chemicals that meet these criteria were potentially released, then the site should

be evaluated for vapor intrusion. This includes evaluating the history of adjacent

properties for potential releases of vapor-forming chemicals that may have affected the

subject site. If there is no reason to believe that a release of a vapor-forming chemical

may have affected the site, then the information supporting this decision should be

documented and the vapor intrusion pathway does not need further evaluation.

Please note, polychlorinated biphenyls (PCBs) and PCB mixtures (i.e., Aroclors) are

considered sufficiently volatile and toxic in the U.S. EPA VISL calculator. However, only

lighter PCB mixtures and degradants would be expected to volatilize at a site. In most

cases, PCBs do not need to be evaluated in a vapor intrusion (VI) assessment; please

contact Ohio EPA if the site assessment identifies PCBs for vapor intrusion on a site.

4

Based on the site assessment decide if further investigation and understanding of the

vapor intrusion pathway is warranted. The potential for a complete vapor intrusion

pathway depends on factors such as current or future land use, distance between

contamination and existing or proposed buildings, preferential pathways, and whether

contaminant plumes are at steady state. A potentially complete or complete vapor

intrusion pathway exists if there is: 1) a potential or confirmed source of a sufficiently

volatile and toxic chemical or chemicals; 2) a current or future mechanism to transport the

chemical; and, 3) a current or future human receptor. Please note, future buildings are to

be reasonably anticipated. If a determination is made that there is no complete or

potentially complete vapor intrusion pathway, this determination must be documented. If

the three factors listed above are present at a site, an investigative workplan that includes

a CSM for evaluating the vapor intrusion pathway should be developed. The CSM is not

static, but continually refined and revised based on data collected at the site.

Flowchart Step 3: Develop a conceptual site model and data quality objectives

3.2 Conceptual Site Model

Site investigations should include the development and refinement of a CSM. The

purpose of a CSM is to provide a conceptual understanding of the potential for exposure

to hazardous contaminants based on knowledge of the sources of contamination present,

release mechanisms to the environment, transport mechanisms, exposure pathways, and

potential receptors. The CSM should include a diagrammatic or schematic representation

that relates the source of contamination to human and ecological receptors and identifies

all potential sources of contamination, the potentially contaminated media, and exposure

pathways. The CSM should evolve as site-specific conditions are better understood and

additional data becomes available, thus the CSM should not be static. The CSM

organizes and communicates information about the site characteristics and is not only a

necessary component of any vapor intrusion site investigation, but an essential decision-

making and communication tool for all interested parties.

For vapor intrusion sites the CSM is integral to the development of a sampling plan. The

CSM will focus on the potential receptors and pathways and is updated as additional data

and information is obtained. Ohio EPA recommends that the following items be included

in a CSM for the vapor intrusion pathway. However, in the early stages of investigation,

not all components listed may be available.

• Primary Sources of Contamination. Provide a list of all volatile chemicals for each

potential source. For each potential contaminant source, describe the release and

provide a list of volatile chemicals released into the environment.

• Secondary Sources of Contamination. Include all the environmental media

potentially contaminated by the primary sources, such as surface soil, subsurface

soil, and ground water. Contaminated building materials, such as concrete

foundations, can be a source area for a potential release to an environmental

medium and should be considered.

5

• Contaminant Transport Mechanisms. For each potentially contaminated

environmental medium, describe the transport mechanism to indoor air, (usually

advection and diffusion through the vadose zone), and describe the characteristics

of the subsurface.

• Exposure Routes. Describe current buildings, potential future building scenarios,

as appropriate, and areas where vapors may accumulate, including smaller

enclosed areas in larger buildings. Discuss any preferential contaminant migration

pathways associated with the buildings, such as foundation cracks, voids, utility

ports, pipes, elevator shafts, sumps, and drain holes.

• Potential Receptors. List all the current and potential future receptors, as

appropriate, that could potentially be exposed to contaminated indoor air from the

vapor intrusion pathway.

A preferential contaminant migration pathway is a pathway of less resistance than typical

pathways available for transport through environmental media, taken by chemicals of

concern (COC) while undergoing diffusion or advection. These pathways, which can be

natural or anthropogenic, are a result of disturbance in natural soil layers, (such as

installation of underground utilities or fractures in bedrock), are more porous and

transmissive, and enable more rapid COC transport. Early in the development of a CSM

and sampling plan, preferential pathways need to be considered, located and potentially

sampled for. For example, it has been observed that utility lines are able to influence the

flow of shallow ground water contaminated with vapor-forming chemicals, and either block

the flow of such ground water, or conversely, facilitate flow of soil gas and contaminated

ground water through the porous bedding material or the pipes themselves. Sewer lines

in particular, due to their construction, have been known to convey vapor-forming

chemicals for long distances from a source. Older sewer lines may be composed of clay,

cast iron or Orangeburg pipe, which may have cracks and voids at joints depending upon

their age. Infrastructure present in older cities and towns may be cracked or detached at

joints due to settling. Utility lines are surrounded by bedding material which is typically

more porous than the surrounding native soils. The presence of any preferential pathway

necessitates an examination of whether vapor-forming chemicals can be transmitted

beyond the assumed 100-foot buffer zone. A study by McHugh, et. al. (2017) showed that

concentrations of vapor-forming chemicals were higher in the basement than the sub-

slab vapor concentrations. Therefore, if a sewer line is within the zone of influence (less

than 100 feet) from a source of vapor-forming chemicals, or there is reason to suspect

that a ground water plume contaminated with vapor-forming chemicals above U.S. EPA

VISLs is interacting with the sewer line, then sampling the line and bedding material

should be planned and included in the sub-surface investigation and field sampling plan.

To document current site conditions, the CSM should be supported with maps,

subsurface cross-sections, site diagrams, and any other site-specific details which may

be pertinent, such as building characteristics. The narrative should clearly describe known

site conditions and state what assumptions were made to generate the CSM. The

6

narrative should include a description of ambient sources and the presence of nearby

potential sources of volatile organic compounds (VOCs) and other volatile chemicals,

such as neighboring dry-cleaning operations. Additional information on the development

of a CSM can be found in guidance published by various entities, including the U.S. EPA

Risk Assessment Guidance for Superfund (U.S. EPA, 1989), Standard Guide for

Developing Conceptual Site Models for Contaminated Sites ASTM E1689 – 95 (ASTM,

2014), Ohio EPA DERR Conceptual Site Models Guidance Document (Ohio EPA, 2015),

and U.S. EPA Guidance on Systematic Planning Using the Data Quality Objectives

Process (U.S. EPA, 2006).

The site evaluation may lead to the conclusion that the vapor intrusion pathway is

incomplete. The following are examples of instances where the vapor intrusion pathway

may be considered incomplete:

• No buildings are present at the site and there is a prohibition on building structures

at the site in the future;

• Absence of sufficiently volatile and toxic chemicals;

• The distance between contamination and existing or proposed buildings is greater

than 100 feet leading to low probability of vapor intrusion, as confirmed with soil

gas data;

• Lack of preferential pathways; or

• Contamination plumes (e.g., ground water, soil gas or sub-slab vapors) are

confirmed to be at steady-state and contaminant concentrations are and will

remain below screening levels.

A checklist of information to assist in the development of a CSM for vapor intrusion and

for planning a soil gas sampling strategy for a site can be found in Appendix A.

3.3 Data Quality Objective Process and Developing a Sample Plan

The scope and objectives of environmental media sampling should be established before

the vapor intrusion investigation is conducted by working through the Data Quality

Objective (DQO) process. For voluntary actions, the DQO process is part of the Phase II

Property Assessment (see OAC 3745-300-07(C)). For RP sites, the CERCLA RI/FS

guidance, RCRA Corrective Action Guidance, Closure Plan Review Guidance and

general U.S. EPA Quality Management documents should be followed when designing a

sampling plan and developing DQOs. The DQOs are qualitative and quantitative

statements that:

• Clarify the study objective.

• Identify the chemicals of concern (COCs).

• Define if the sample will provide qualitative or quantitative information.

• Define the type, quantity, and quality of each piece of data collected in the study.

• Determine required analytical detection limits.

7

• Define how each sample will be used to assess whether vapors are intruding into

buildings.

• Determine the most appropriate locations, sampling method, and sampling

duration for data collection.

• Specify the amount of acceptable uncertainty in the sampling results.

• Specify how the data will be used to test the exposure hypothesis.

Additional information on the DQO process can be found in U.S. EPA. Guidance on

Systematic Planning Using the Data Quality Objectives Process (February 2006) at

https://www.epa.gov/quality and Ohio EPA, Data Quality Objectives Process Summary,

DERR-00-DI-32, Internal Guidance Document, January 2002 at

https://www.epa.ohio.gov/portals/30/rules/Data%20Quality%20Objectives%20Process%

20Summary.pdf.

The type of environmental media sampled and sampling strategy for the evaluation of the

vapor intrusion pathway is dependent on release history, prior site investigations, the

CSM, and whether the site is being evaluated under the VAP or RP programs.

For RP sites, the sampling strategy is directed by the RI/FS, RFI/CMS or unit closure site

characterization process. For VAP sites, the Phase I will direct the sampling with the

results presented in the Phase II. For RP sites, the sampling strategy should be sufficient

to characterize the complete nature and extent of contamination. For VAP sites the

sampling strategy may be tailored to the remedy selection. During site characterization,

the sampling and analysis plan that was developed during the project planning is

implemented and field data are collected and analyzed to determine if a complete vapor

intrusion pathway exists and to what extent the site poses a threat to human health and

the environment. This is an iterative process and the resulting data and information will

be used for selecting a remedy for the site.

The U.S. EPA OSWER Technical Guide for Assessing and Mitigating the Vapor Intrusion

Pathway from Subsurface Vapor Sources to Indoor Air (June 2015) recommends

collecting multiple rounds of sampling at multiple locations to evaluate spatial and

temporal variations of the concentrations of COCs in environmental media. Spatial and

temporal variability factors to consider include depth to ground water, heterogeneity in

subsurface materials, weather conditions, building operations, building construction and

age, interior compartmentalization, preferential contaminant migration pathways (such as

foundation cracks, sumps and utilities), and whether the site is developed or

undeveloped.

In most cases, soil gas data is part of the multiple lines of evidence approach to determine

whether the vapor intrusion pathway is potentially complete from contaminated soil or

ground water. For existing buildings, sub-slab vapor concentrations best reveal the

potential for vapor intrusion directly into the building. The flow chart in Figure 1 does not

require that environmental media be sampled in a linear fashion (i.e., soil and ground

water, then soil gas, then sub-slab vapor, and finally indoor air). However, where

receptors are potentially being exposed, the preference is to determine impacts from soil

8

gas, soil, and ground water first to determine if a potential for vapor intrusion exists. A

more detailed discussion of the relative importance and iterative sampling of different

media is provided in Sections 4.3, 4.5, and 6.4. If soil gas, soil and/or ground water data

indicate a potential risk to building occupants, then sub-slab vapor and indoor air data

should be collected and used in the risk evaluations. Special considerations are advisable

when evaluating residential properties and/or imminent hazard situations and are

discussed in Appendix B and Section 11.0, respectively.

Ambient air and sub-slab vapor should be collected when sampling indoor air to aid in

data interpretation and determining if vapor intrusion is occurring. Although measuring

indoor air concentration is a direct measurement at the exposure point, many factors can

influence indoor air results, including materials used or stored indoors, disturbance of

sampling equipment during testing, and the possibility of ventilating the building during

the sample event (i.e., opening doors/windows). Additionally, indoor air values can be

influenced by concentrations of volatile chemicals in ambient outdoor air that are

unrelated to releases in soil or ground water.

For all vapor-forming chemical releases, if the data collected during the site investigation

indicates existing or future buildings at a site or near the site are greater than 100 feet

laterally from the known extent of subsurface contamination above screening levels and

there are no preferential pathways (e.g., sewer lines) that can be a direct conduit from a

vapor source to a building, then vapor intrusion is not likely under the current site

conditions, and no further consideration of the exposure pathway should be needed until

such time site conditions change in a way that warrant a vapor intrusion investigation

(e.g., a building is built directly above the source area). For relatively small releases

compromised of only petroleum hydrocarbon (PHC), such as underground storage tank

(UST) sites, a lateral separation distance of 30 feet and a vertical separation distance of

15 feet (above LNAPL) or 6 feet (above dissolved sources) can be applied instead of the

default 100 feet. Sites with a potential for larger petroleum releases, such as bulk plants,

refineries, petrochemical plants, or pipelines, or sites where lead scavengers were used

or stored should use the 100 feet lateral separation distance recommended for non-PHC

VOCs. See Sections 9.2 and 9.3 for additional information regarding PHC lateral and

vertical separation distances.

Evaluations of building distance from contamination should only be conducted if the

movement of subsurface contamination has reached steady-state conditions (i.e., when

the maximum migration potential of the subsurface plumes has been reached). For

ground water, the migration potential can be evaluated with data from routine sampling

of ground water monitoring wells. If COCs in ground water indicate stable or decreasing

contaminant trends, the maximum contaminant migration for ground water has probably

occurred. For soil gas, a similar evaluation can be conducted if routine sampling data is

available from permanent or temporary sampling points. If sufficient time has passed

since the chemical release to allow for diffusional movement to the building in question,

then steady-state conditions have probably occurred. If soil gas or ground water

contaminant plumes are increasing, 100 feet is not an appropriate distance for potential

pathway elimination.

9

When evaluating the distances between subsurface contaminant plumes and buildings,

it is important to consider whether preferential pathways exist which could allow vapors

to migrate beyond the lateral separation distance. These preferential pathways could be

either natural or anthropogenic. Examples of preferential pathways include fractures,

macropores, gravel base for utility conduits, and subsurface drains, etc.

Flowchart Step 4: Sample environmental media

4.0 SOIL GAS AND SUB-SLAB VAPOR SAMPLING PROCEDURES

The following section provides basic guidelines for conducting soil gas and sub-slab vapor

sampling for assessing the vapor intrusion pathway. Soil gas sampling refers to samples

collected outside of a building footprint and sub-slab vapor sampling refers to samples

collected from directly underneath an existing building. Appendix C contains Ohio EPA

DERR’s standard operating procedures for installing soil gas probes, sub-slab vapor

probes and direct push techniques for collection of soil gas.

Soil gas and sub-slab vapor sampling can be used for a number of purposes including

initial site characterization, delineation of impacts from ground water plumes, identification

of source areas and potential receptors, remediation and post-remediation monitoring,

and for developing and refining a CSM.

4.1 Soil Gas and Sub-Slab Vapor Sample Collection and Analysis

Depending on the scope of the study and the DQOs, samples may be collected using

devices such as gas-tight syringes, Tedlar

®

bags, passive sorbent samplers or Summa

canisters. Gas tight syringes are appropriate only when an on-site field laboratory is used,

and samples are analyzed immediately following sample collection. Field screening and

use of a mobile lab are acceptable in order to refine DQOs by conducting on-site, real

time field analysis. Alternative soil gas and sub-slab vapor sampling options can be

proposed to Ohio EPA for considerations.

Prior to collecting the sample for analysis, Ohio EPA DERR recommends purging three

tubing volumes or conducting a purge test until parameters (e.g., oxygen, carbon

monoxide, or VOCs) stabilize in order to determine the optimal purge volume for the

location. The purge volume should be consistent for all samples collected from the study

area. An approximate 10-minute delay should occur between purging and sampling.

When purging or collecting samples using a vacuum pump or an evacuated canister, the

vacuum applied to the probe should not exceed ten inches of mercury or 100 inches water

and the flow rate generally should not exceed 200 milliliters per minute. This should limit

the potential for ambient air being drawn into the sample from the ground surface and it

should limit desorbing of vapors from contaminated soils.

To maintain sample integrity:

10

• The recommended maximum holding times for samples should not be exceeded.

The laboratory should be contacted for holding times and to ensure the sampler

uses the best collection method.

• If stored samples are to be subjected to changes in ambient pressure (such as

shipping by air), canisters are recommended (ITRC, 2007).

• Samples should not be chilled during storage unless specified by the method.

• Tedlar

®

bag samples should be kept out of direct sunlight.

• All sampling records should be completed and maintained (e.g., chain of custody,

sample data forms).

The appropriate sample method is dependent on the DQOs developed for the project.

The contract laboratory can provide information on appropriate sample volume for

analysis. Samples should be analyzed for the appropriate COCs, including breakdown

products. Syringe samples and Tedlar® bags generally are only acceptable for qualitative

and possibly semi-quantitative analyses. Quantitative analysis by TO-15/8260 or TO-17

should be used for human health risk assessments. The analytical method used should

be able to identify and quantify the target analytes and be capable of meeting program

specific requirements. Sample results submitted to Ohio EPA DERR should be reported

in units of ppbv and/or µg/m

3

. Lower explosive limit (LEL) percentages should be used

for explosive gas determinations. Soil gas and sub-slab vapor sampling field data should

be recorded on either the Soil Gas Probe Field Data Report Form (Appendix D) or the

Indoor Air/Sub-Slab Vapor Sampling Form (Appendix E) or equivalent forms, as

applicable, and submitted with the results.

Utility and sewer lines should be located prior to conducting sampling for safety and to

aid in locating samples. Contact a local municipal utility authority to obtain accurate layout

of utilities and sewer lines in immediate vicinity of the site before a subsurface

investigation. In Ohio, it is 8-1-1, the Ohio Utilities Protection Service, which coordinates

with local utility contacts. The utilities and sewer lines should be depicted on the cross

section of the CSM, and a determination should be made if there is a potential for utility

or sewer lines to interact with shallow ground water. Utility lines within 100-feet of a known

vapor-forming chemical release should be screened via a Photoionization detector (PID)

or equivalent field screening instrument.

A utility line preferential pathway investigation should take into consideration the type,

depth, diameter and construction specifications of all lines and bedding material, utilizing

historical resources. Screen sewer gas and determine depth of lines through manhole

apertures if possible, using a PID. Sampling in sewer lines and the bedding around utilities

requires caution and expertise given the risks involved if utilities are pierced or damaged.

The following resources discuss techniques which can be utilized to sample for soil gas

in and around utilities:

• Indiana Department of Environmental Management (IDEM): Investigation of

Manmade of Preferential Pathways, Office of Land Quality, August 2015:

https://www.in.gov/idem/cleanups/files/remediation_tech_guidance_investigation

_mpp.pdf

11

• Massachusetts Department of Environmental Protection (MassDEP) Vapor

Intrusion Guidance, Site Investigation, Mitigation and Closure, October 2016:

https://www.mass.gov/files/documents/2016/10/nu/vapor-intrusion-guidance-10-

14-2016.pdf

4.2 Analytical Detection Limits

Analytical detection or reporting limits for soil gas samples should be sufficiently low to

adequately evaluate the vapor intrusion pathway per the project’s DQOs. For VAP sites,

an estimate of the applicable standard, adjusted for the presence of multiple chemicals,

provides the basis for the minimum detection limits. For screening at Ohio EPA DERR

RP sites, the minimum detection limit is determined by the appropriate screening value.

More information on the analytical methods and reporting limits can be found in Appendix

F.

4.3 Soil Gas Sampling

In many cases, soil gas sampling is essential in evaluating the vapor intrusion pathway.

There are a variety of techniques for obtaining these samples, from placing probes using

boring devices to measuring soil gas using passive-type samplers. Whatever technique

is chosen, the soil lithography and stratigraphy should be determined using on-site data

from previous investigations, data from nearby sites, or based on information from county

soil surveys to aid in characterizing the source and transport mechanisms. Other pertinent

information that should be considered when planning a soil gas investigation include

depth to ground water and the presence of perched impermeable zones. This information

should be used to determine appropriate sampling depths. Ohio EPA generally expects

that initial soil gas samples should be taken above the capillary fringe to determine if a

contamination source is of sufficient concentration to warrant additional soil gas sampling

or to conduct sub-slab vapor sampling. It may be necessary to install probes at multiple

depths to evaluate the vertical distribution of contaminants in soil gas. For vertical

delineation, soil gas samples could be collected at various depths (e.g., 5 feet, 10 feet,

and 20 feet below ground surface (bgs)) to demonstrate attenuation and the likelihood

that the vapor intrusion pathway is complete. Ohio EPA DERR recommends that vadose

zone monitoring points for sample collection be installed to evaluate the temporal

variations in soil gas concentrations. Soil gas sampling should be postponed at least 24-

hours after a major rain event (one-half inch or more) and the sampling area must be free

of ponded water.

Soil gas sample locations should be biased toward the source, if known, or toward highest

expected concentrations. If a property is developed, sub-slab vapor sampling rather than

soil gas sampling is preferred to evaluate the potential vapor intrusion pathway to the

building. If sub-slab vapor sampling is not practical, then soil gas samples should be

collected as close to the building as possible. However, keep in mind that soil gas samples

may exhibit a high degree of spatial and temporal variability (U.S. EPA, 2015b). According

to U.S. EPA (2015b), “…soil gas concentrations measured exterior to a building may not

12

be representative of sub-slab concentrations measured directly beneath the building

foundation sub-slab. The bias introduced by these factors may be high or low depending

on climatic and building conditions and the extent to which the samples accurately

represent the spatial and temporal variability of concentrations under the building.” If soil

gas samples are being collected in lieu of sub-slab samples, then bias should be given to

preferential pathways, such as utilities and fill materials located at the site to account for

this potential variability. It is important to note that situations may exist where vertical

fractures may provide preferential pathways, in such instances sub-slab vapor sampling

may be necessary to adequately evaluate the indoor air pathway.

Ohio EPA DERR recommends that a minimum of two rounds of soil gas data be collected

to evaluate the vapor intrusion pathway. However, early or interim response actions may

be required following one round of sampling. The two rounds will begin to estimate

temporal and seasonal variations at the site and other site-specific factors which may

influence vapor migration. Since two rounds constitute a limited database, the maximum

concentration detected should be used to evaluate potential risk. Based on these results,

additional samples may be required depending on the source strength, plume movement

and how soil gas concentrations compare to screening levels. If soil gas samples exceed

screening values and buildings are within 100 feet of the sample location for non-

petroleum vapor-forming chemicals and within 30 feet of PHC vapor-forming chemicals,

then sub-slab vapor samples and/or indoor air samples should be collected to further

evaluate the vapor intrusion risk pathway. For further information on evaluating petroleum

releases and their inclusion zones see Section 9.0.

For undeveloped sites with vapor-forming chemical contamination, soil gas samples

should be collected to evaluate the potential for vapor intrusion should the property be

developed in the future. The number and depth of soil gas samples should be sufficient

to evaluate concentrations in soil gas and attenuation of soil gas as it migrates to the

surface. Reassessment of the vapor intrusion pathway may be warranted once structures

are built on the site to evaluate the site-specific situation.

Generally, soil gas samples should not be collected at depths shallower than five feet bgs

due to the potential for atmospheric interference. Ambient air may infiltrate the soil column

and could result in dilution of the soil gas sample near the surface. For sites where the

depth to ground water or the soil source is less than five feet, but sub-slab sampling

beneath an enclosed structure is not an option, an attempt should be made to collect soil

gas samples from beneath existing impermeable surfaces such as outdoor patios, parking

lots, or roads. When shallow (< 5 feet bgs) soil gas sampling is performed, leak testing is

a critical element of the sampling to verify the integrity of the vapor probe seal and the

quality of the data (Section 4.7). If an impermeable surface is not present beneath a

structure or in outdoor areas, then it may be more appropriate to rely on other lines of

evidence such as passive soil gas sampling, ground water sampling, crawl space or

indoor air sampling to evaluate the vapor intrusion pathway.

13

4.4 Soil Gas Probes

Soil gas sampling probes are either temporary or permanent. Temporary soil gas probes

are only sampled once, and all equipment is removed upon sample completion.

Permanent soil gas probes are sampled over time to evaluate seasonal, temporal or other

variations in concentrations. When possible, permanent soil gas probes should be

installed when collecting soil gas samples for risk assessments. Figure 2 shows several

types of soil gas probes (NJDEP, 2005). Whether installing a temporary or permanent

soil gas probe, it is necessary to prevent ambient air from diluting the soil gas sample. A

leak test should be performed to verify the integrity of the vapor probe seal. For further

information on leak testing refer to Section 4.7.

Figure 2. Examples of Soil Gas Sampling Probes (NJDEP, 2005)

Temporary vapor probes can be installed by a variety of methods. The most common

methods are direct push and manual slide hammer. These methods allow sample tubing

to be placed at the desired depth for sampling then removed once a sample is collected.

Temporary vapor probes use a retractable or removable drive tip. Typically, ¼” nylon,

14

Teflon or polyethylene tubing is used to collect subsurface vapors for sampling in

temporary applications.

Figure 3 is a schematic of a permanent soil gas probe. Samples from permanent soil gas

probes should be collected over an appropriate seasonal or temporal time frame in order

to adequately evaluate the risk from the contaminants detected. Permanent soil gas

probes typically consist of a screen or sample port installed at the tip or near the bottom

of the tubing. Stainless steel, Teflon or nylon tubing are preferred in permanent

applications. Tubing selections should be based upon duration of sampling, type of

COCs, and how long the sampling point needs to remain in place (see Appendix G for

comparison of sample tubing type to vapor absorption). Common installation methods

include direct push equipment (e.g., Geoprobe®), hollow stem auger and manual slide

hammer (see Appendix C for the standard operating procedure for advancing soil gas

probes). The soil gas probe is installed to a specific depth in a bore hole created with a

slide hammer, direct-push system or a hollow stem auger. Sand is placed in the annulus

around the sampling port screen and the remainder of the bore hole is sealed with

hydrated bentonite. The tubing is usually labeled and capped at the surface. The bore

hole is completed with a protective cover at the surface.

15

Figure 3. Permanent Soil Gas Probe Schematic

4.5 Sub-Slab Vapor Sampling and Data

Sub-slab vapor data, which is collected from under the foundation floor and is within the

advective envelope of building-driven depressurization, indicate whether contaminants

have accumulated directly under the building. Analytical detection limits should be low

enough to effectively evaluate the indoor air risk posed by the vapor intrusion pathway.

See Section 12.0 for more information on evaluating the indoor air risk from vapor

intrusion by calculating risk levels.

16

When there is an indication of a potentially complete exposure pathway, proceeding

directly to sub-slab vapor sampling may shorten the investigation. However, if the purpose

of an investigation is to directly link a known or suspected source to vapor intrusion, then

sub-slab vapor sampling is only one step in the process. In this situation, it is important

to also consider collecting soil, ground water, soil gas, sub-slab vapor, utility or sewer

line, and indoor air samples, as applicable, in order to link the source to the exposure

point (i.e., the indoor air). When collecting sub-slab vapor samples, Ohio EPA DERR

recommends the event be paired with indoor air samples and an ambient air sample in

order to compare the chemicals detected in these samples to aid in vapor intrusion

assessment data interpretation and conclusions.

If COCs are detected in sub-slab vapor samples above screening levels, then installation

of permanent sampling ports may be necessary to determine the temporal variability of

the data. However, the collection of sub-slab vapor samples can be inconvenient to

building occupants since it requires the removal of floor coverings and drilling through the

foundation slab, thus clear communication with inhabitants and property owners about

the sampling process is needed.

When sub-slab vapor sampling is conducted, an appropriate number of samples should

be taken to characterize the sub-slab area. The number, type (time-integrated or grab

samples), and locations of the sub-slab samples should be determined based on

information collected during the building survey, an understanding of the building

foundation(s), the COCs (e.g., PHC versus chlorinated), the results from nearby soil gas,

ground water, and/or soil sampling, and the site-specific DQOs. At residential properties,

at least two sub-slab vapor samples should be taken with one sample taken in the center

of the building’s foundation. For foundations greater than 5,000 square feet, at a minimum

sub-slab vapor samples should be collected approximately every 2,000 to 5,000 square

feet from biased locations, such as locations directly over source areas, maximum ground

water concentration areas or near preferential pathways, and one of the sample locations

should be located near the center of the building foundation. If indoor air sampling is not

performed concurrently, but is subsequently needed, the indoor air samples should be

analyzed only for the chemicals detected in the sub-slab vapor (see Section 5.0). By

selecting for the chemicals detected in the sub-slab samples, the chance of inadvertent

inclusion of indoor sources of chemicals can be decreased or eliminated. However,

analyzing indoor air samples for the method’s full analyte list can be necessary when the

full nature and extent of contamination has not yet been determined.

During sub-slab sampling care should be taken to not damage the integrity of the slab or

underground utilities. Sub-slab utilities or tension cables need to be located prior to

selecting sampling locations. Blueprints can assist in locating these features. A private

utility locating service should be contracted to determine the presence of sub-slab utilities

or tension cables if there is no information available from other sources. Since penetrating

the slab creates a preferential pathway, proper sealing of the sampling port is essential

to avoid leaks. Sub-slab sampling should be avoided in areas where ground water might

intersect the slab. Figure 4 is a schematic of a sub-slab vapor probe made with Swagelok

®

parts. Another alternative is the Cox-Colvin vapor pin

®

.

17

Figure 4. Example of a Sub-Slab Vapor Probe

Multiple sampling rounds may be needed to adequately account for temporal variability

due to the “substantial spatial variability in sub-slab vapor concentrations” (U.S. EPA,

2015b). Generally, if both indoor air and sub-slab vapor samples are collected during the

most desirable sampling conditions to evaluate reasonable maximum exposure and both

are non-detect or below screening values, then one round of sampling may be sufficient.

If, however, COCs are detected in both sub-slab vapor and indoor air, or if indoor air is

non-detect, but COCs are elevated in sub-slab vapor, soil gas or other media, then

multiple rounds of sampling (or preemptive mitigation) are typically required. The number

of additional rounds depends on the chemical concentrations and other site-specific

circumstances. For example, long-term quarterly, semi-annual, or annual sampling may

be necessary in situations where vapor concentrations are variable, or to verify remedy

effectiveness.

4.6 Sampling Basements with Dirt Floors and Crawl Spaces

If a basement or crawl space has a dirt floor, any sampling conducted should be with an

evacuated air canister in the same manner as for sampling indoor air.

18

4.7 Leak Testing

Atmospheric air drawn into a soil gas or sub-slab vapor sample can result in dilution of

the sample. Negatively biased samples, resulting from the inclusion of atmospheric air

during soil gas or sub-slab vapor sampling, will be unusable to demonstrate that a vapor

intrusion pathway is incomplete. To ensure that valid soil gas and sub-slab vapor samples

are collected, leak tests on the probes should be conducted to demonstrate that dilution

is not a concern. It is often desirable to conduct leak testing with utilization of tracer gases

or a water dam. The water dam can consist of a secondary, larger hole surrounding the

smaller hole that the vapor sampling point is installed through (such as the hole used for

flush mount Vapor Pin® installation) or can be a ring temporarily sealed to the floor with

VOC-free putty. The water dam is filled with water after connecting the tubing to the

Summa canister. Changes in water level or appearance of bubbles during sampling are

indicative of possible leaks.

Soil gas probes should be installed greater than five feet bgs and should be tested for

integrity with a particular emphasis on the sampling train (i.e., the tubing or the

connectors). This testing is usually performed with compounds not found at the site that

enshroud the sampling train. Atmospheric oxygen and CO

2

may also be considered for

leak tests. As a general rule, shallow soil gas samples (i.e., less than 5 feet bgs), are

discouraged. However, if shallow soil gas sampling is the only option at a site, then leak

testing should be utilized, and sampling must be discussed with Ohio EPA DERR

personnel prior to collection of these samples. Temporary soil gas probes should be

abandoned immediately after the investigation is concluded. Sub-slab vapor sample

collection can also be affected by leaks from surface air and a sub-set of these samples

should also have leak tests performed. In addition to tracer gas leak tests, a mechanical

leakage test of the sampling train should be considered, such as Shut-in Test as proposed

by McAlary et. al. (2009). This test involves pulling a vacuum on the tubing and valves

used to construct the sampling train. Typically, a vacuum of 100 inches of water is applied

to the “closed-off” sampling train and potential leaks are verified with an in-line vacuum

gauge.

Depending on the contaminants of concern a number of different compounds can be used

as a tracer, as shown in Table 1. Sulfur hexafluoride (SF

6

), perfluorhydrocarbons and

helium are commonly used as tracers because they are readily available, have low

toxicity, and can be monitored with portable measurement devices. Isopropanol can also

be used as a tracer but requires laboratory analysis for the tracer. In all cases the same

tracer should be used for all sampling probes at any given site. The leak test should be

conducted using a tracer that is not expected to be present in the soil gas or sub-slab

vapor being tested. When choosing a liquid tracer, check with the laboratory to determine

the reporting limit for the proposed tracer. Ideally, the reporting limit for the tracer should

be similar to the constituents present in the soil gas or sub-slab vapor.

Infiltration of atmospheric air during sampling may also be indirectly evaluated through

the measurement of oxygen and carbon dioxide concentration differences due to the

presence or absence of petroleum hydrocarbon degradation. For example, if oxygen

19

concentrations at a probe installed within a petroleum hydrocarbon source area are at

atmospheric levels, the soil gas data should not be considered reliable and the probe seal

should be modified and the probe re-sampled, because oxygen levels would be expected

to have been depleted in the biological degradation process. Care should be exercised

using this logic when investigating sub-slab vapor as the absence or presence of a robust

microbial community may be questionable. The Soil Gas Probe Field Data Report Form

in Appendix D is useful for recording data when conducting soil gas evaluations. Table 1

lists advantages and disadvantages of common tracer compounds.

20

Table 1. Common Tracers Advantages and Disadvantages

Tracer

Advantages

Disadvantages

Helium

Can check for leaks on site

with handheld detector.

Can quantify amount of

leakage accurately.

Does not interfere in TO-15

analysis.

Party-grade helium may have low VOC

contamination. If used, send a QC sample